A kind of preparation method of silicon germanium black phosphorene pin heterojunction solar cell

A technology of solar cells and black phosphorene, which is applied in the field of solar cells, can solve problems such as living environment disasters, greenhouse effects, and environmental pollution, and achieve the effects of simple preparation methods, improved absorption efficiency, and improved photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] see Figure 1-6 , the present invention firstly provides a method for preparing a silicon germanium black phosphorene PIN heterojunction solar cell, specifically comprising the following steps:

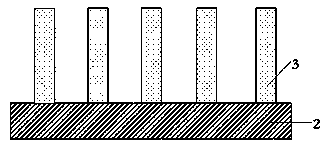

[0017] see figure 1 , providing an N-type silicon substrate 2, and cleaning the N-type silicon substrate 2;

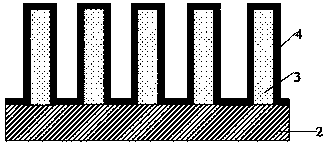

[0018] see figure 2 , using dry etching or wet etching to prepare an N-type silicon nanowire array 3 in the N-type silicon substrate 2 .

[0019] see image 3 , using the PECVD method to deposit an intrinsic amorphous germanium layer 4 with a thickness of 20-100 nanometers on the N-type silicon nanowire array 3;

[0020] see Figure 4 , using a liquid phase stripping method to form a solution containing black phosphorene, and spin-coating the solution containing black phosphorene on the intrinsic amorphous germanium layer 5 to obtain a P-type black phosphorene layer 5 with a thickness of 20-150 nanometers;

Embodiment 1

[0024] A method for preparing a silicon-germanium black phosphorene PIN heterojunction solar cell, specifically comprising the following steps:

[0025] First, the N-type silicon substrate was ultrasonically cleaned in acetone, ethanol, and deionized water for 20 minutes; 2 SO 4 :H 2 o 2 The mixed solution was heated to 110° C. for 1 hour, then rinsed with deionized water and dried with a nitrogen gun, and set aside.

[0026] Next, immerse the N-type silicon substrate in an aqueous solution containing 4.8M hydrofluoric acid and 0.02M silver nitrate, react at room temperature for 20-50 minutes, take out the etched N-type silicon substrate, and clean it to obtain an N-type silicon substrate. In the silicon nanowire array, by controlling the reaction time, the length of a single silicon nanowire in the N-type silicon nanowire array is 0.5-1 micron, the diameter of the single silicon nanowire is 50-100 nanometers, and the diameter of the adjacent silicon nanowire is The pitch ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com