Microwave attenuator

A microwave attenuation and metal wire technology, which is applied to waveguide-type devices, circuits, electrical components, etc., can solve the problems that attenuators cannot take into account, it is difficult to achieve continuous changes in attenuation, and the structure is complex. integrated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

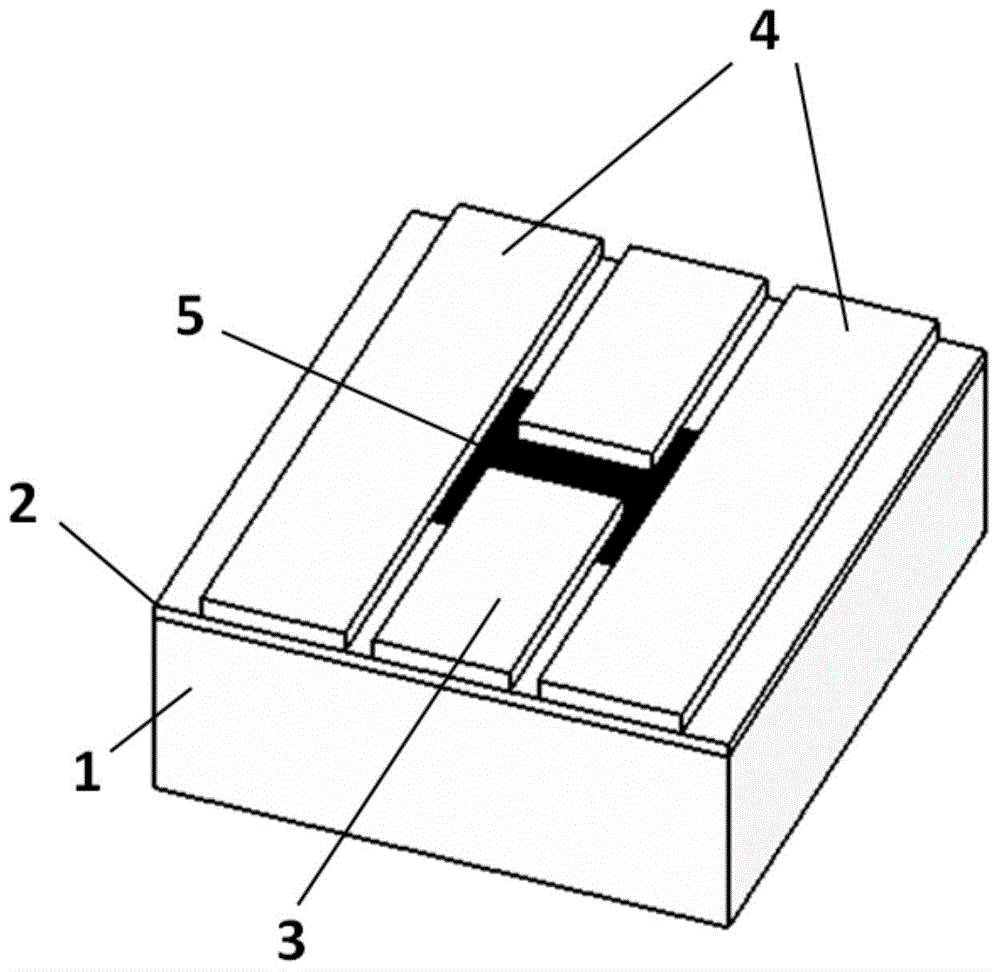

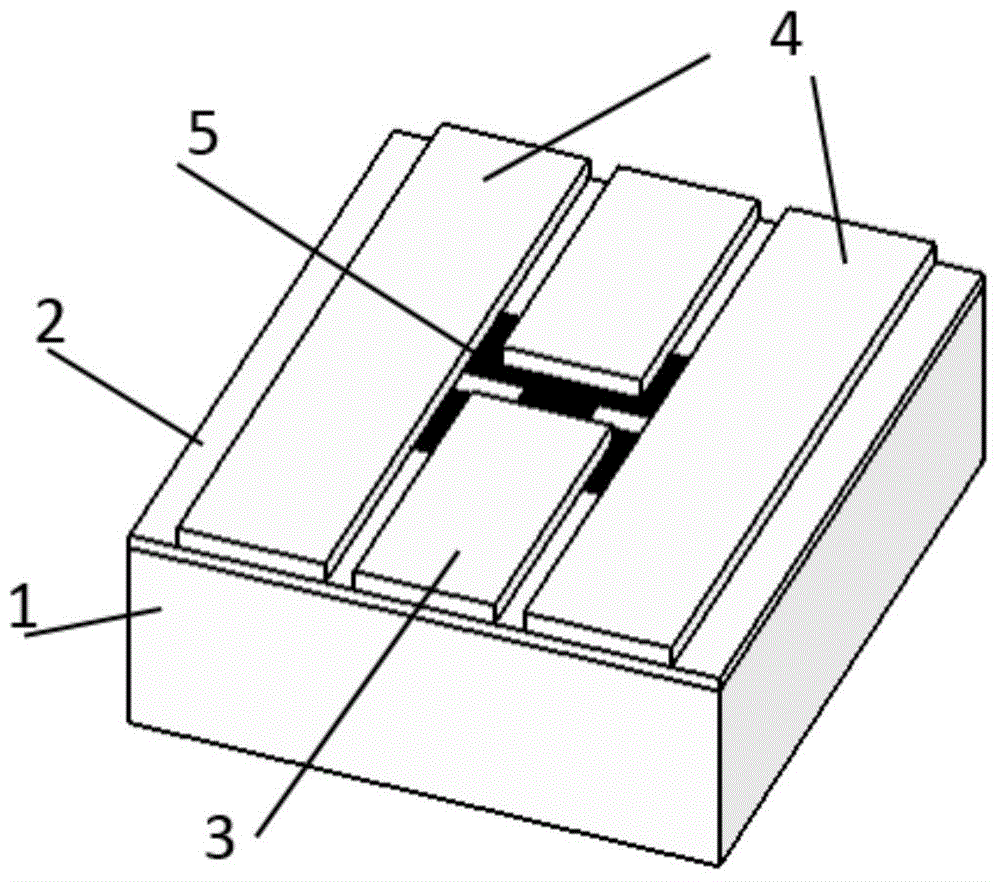

[0015] Embodiment 1: A graphene coplanar waveguide fixed attenuator. Such as figure 1 As shown, it includes a silicon substrate 1 , a silicon dioxide dielectric layer 2 , a copper or aluminum wire 3 , a copper or aluminum ground wire 4 and a graphene film resistor 5 .

[0016] During production, the silicon wafer is first oxidized, and silicon dioxide with a thickness of about 20 μm is formed on the surface of the silicon wafer as a dielectric layer; secondly, a single-layer graphene is prepared and etched on the dielectric layer, and the shape is about 360 μm in width and 300 μm in length Afterwards, prepare the wire and the ground wire, the wire width is 190 μm, leave a 20 μm long gap in the middle, the center of the gap coincides with the center of the graphene film resistor, the ground wire is 250 μm wide, and 20 μm away from the wire.

[0017] The specific process for preparing single-layer graphene can be grown by chemical vapor deposition (CVD) or mechanically exfoliat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com