Wet type air adsorbing purifying device and method

A wet air and purification device technology, applied in chemical instruments and methods, combined devices, separation methods, etc., can solve the problems of corona electrode failure, heavy cleaning and maintenance workload, secondary pollution, etc., to ensure the cleaning effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

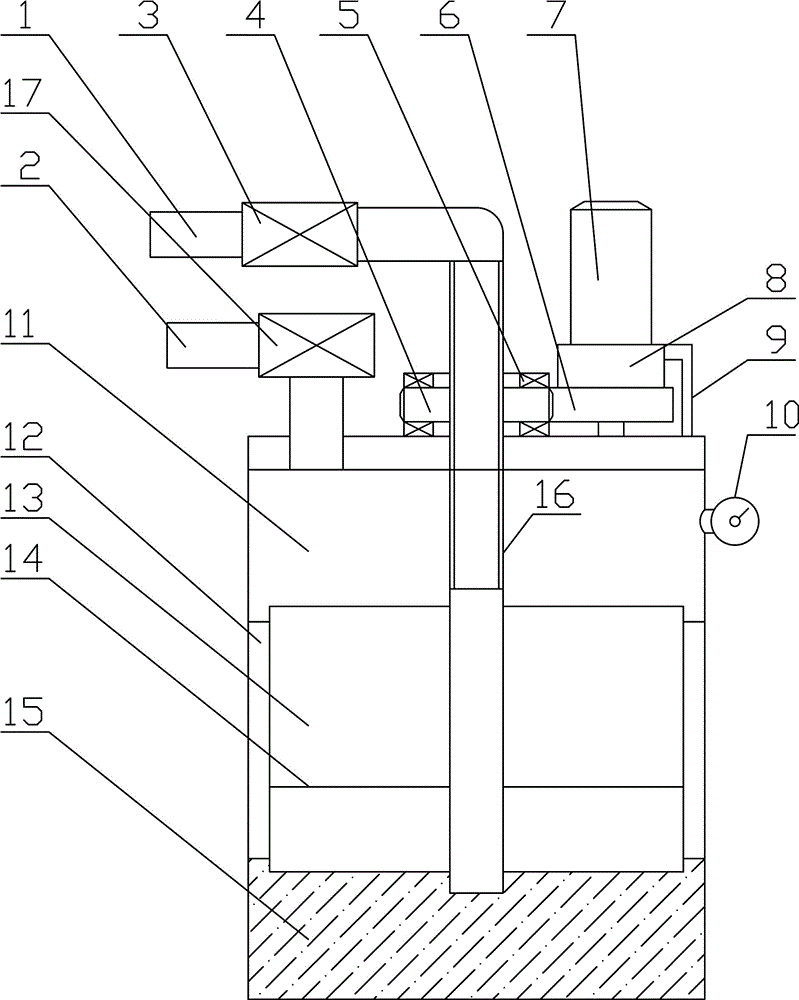

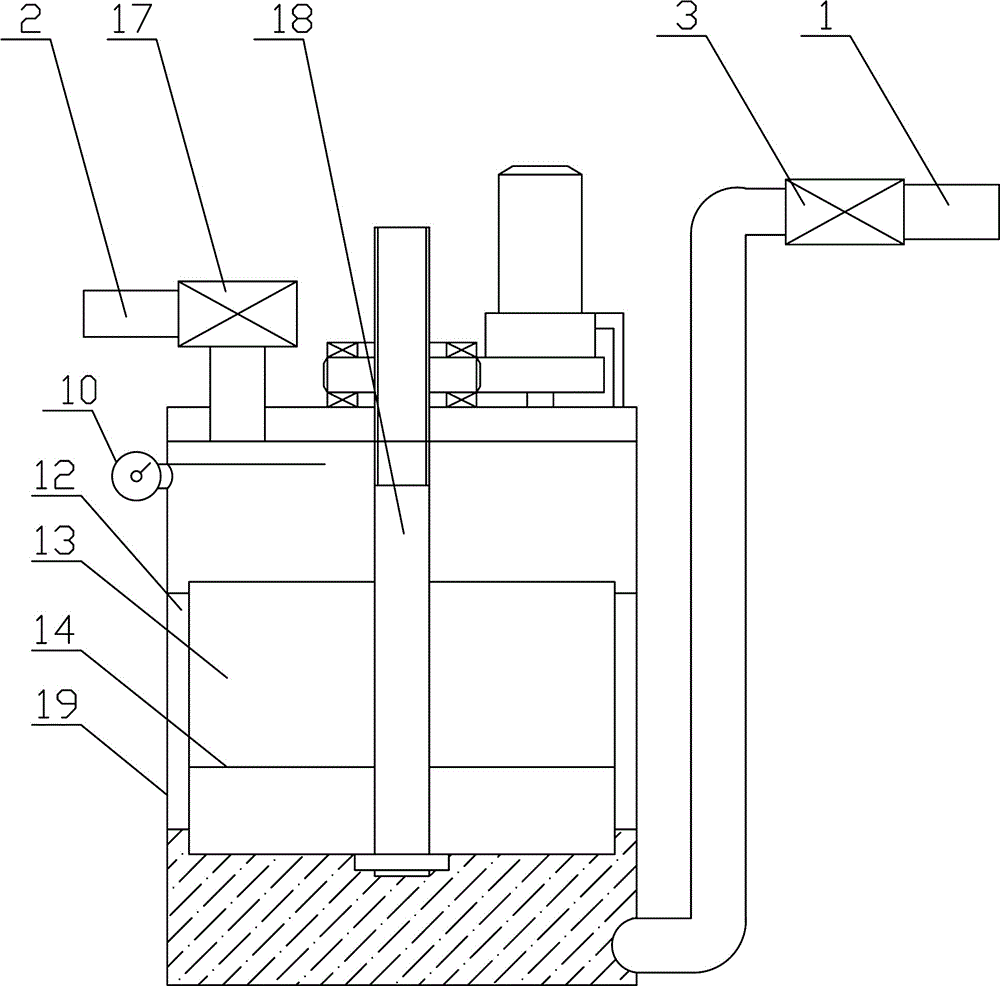

[0032] like figure 1 , 2 Among them, a kind of wet air adsorption purification device comprises cylinder body 19, and cylinder body is preferably cylindrical, and the top of cylinder body is provided with movable top cover, and cylinder body 19 and top cover form the structure of sealing, and cylinder body 19 is provided with The adsorption block 13, preferably, the adsorption block 13 is a porous structure. Examples are sponges or porous ceramics, but also blocks filled with activated carbon, such as cages filled with block activated carbon.

[0033] The cylinder 19 is filled with an eluent 15, preferably, the eluent 15 includes the following components by weight: 0.5-0.8% of low-foam cleaning agent, 2.5-3.5% of polyaluminum chloride, 3.5-5.5% of acetic acid %, alcohol 3~5%, and the balance is water. The low-foaming cleaning agent is a commercially available low-foaming water-based cleaning agent, which is compounded by various surfactants, penetrating agents and auxiliari...

Embodiment 2

[0046] On the basis of embodiment 1, a kind of wet air adsorption purification method comprises the following steps:

[0047] 1. An adsorption block 13 that can be raised and lowered and whose edge forms a sliding seal with the inner wall of the cylinder is arranged in the cylinder body 19, and an eluent 15 is arranged in the cylinder body, and the adsorption block 13 is partially submerged in the eluent 15;

[0048] 2. Use the air supply device to make air enter the eluent 15 and pass through the adsorption block 13 to purify the air;

[0049] 3. A pressure sensor 10 is set above the adsorption block 13, and the height of the adsorption block 13 is adjusted through a lifting device according to the pressure sensor 10, so that the immersion line 14 of the adsorption block 13 in the eluent 15 remains unchanged;

[0050] Through the above steps to achieve continuous air purification effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com