Granulator

A granulator and cutter technology, applied in the field of mechanical equipment, can solve the problems of complex granulator structure, uneven magnetic ring batching, uneven particle size, etc., and achieve the effects of less molding difficulty, low working noise, and avoiding uneven batching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing of description, the present invention is described in further detail:

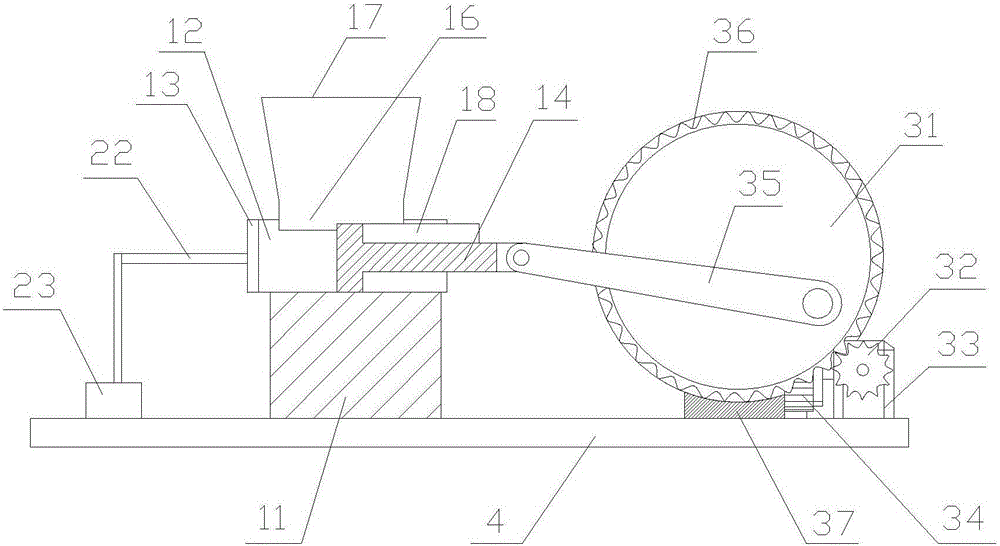

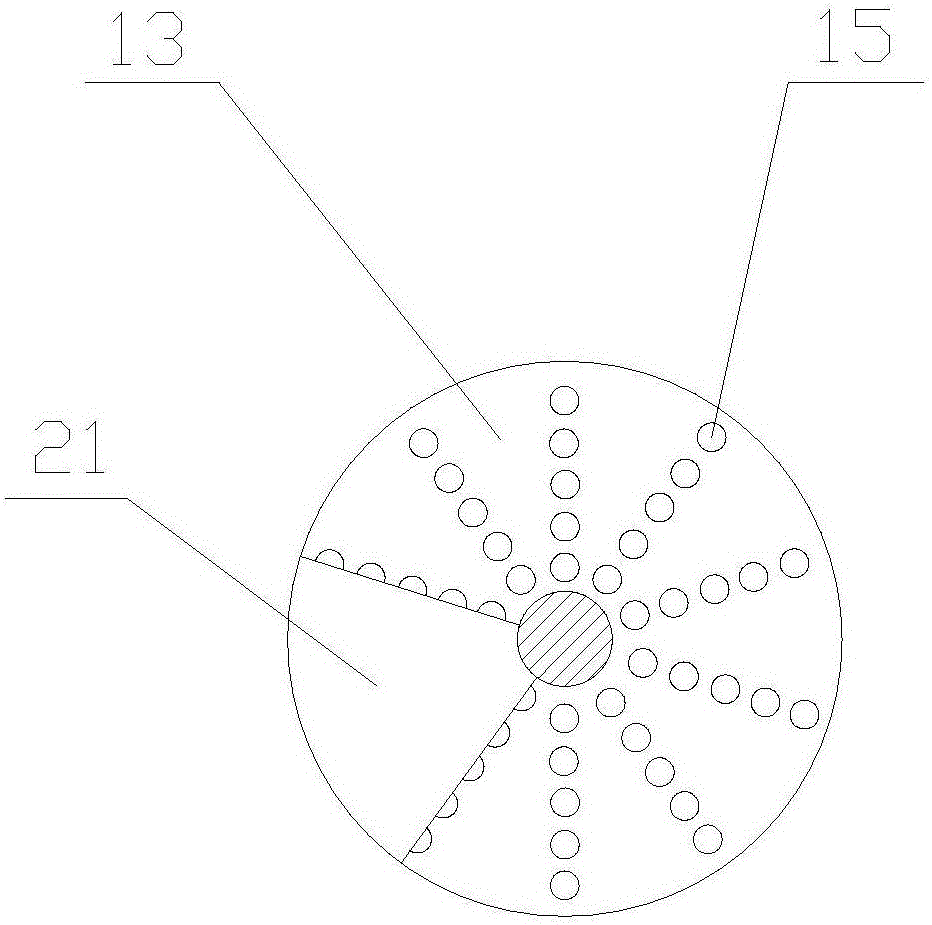

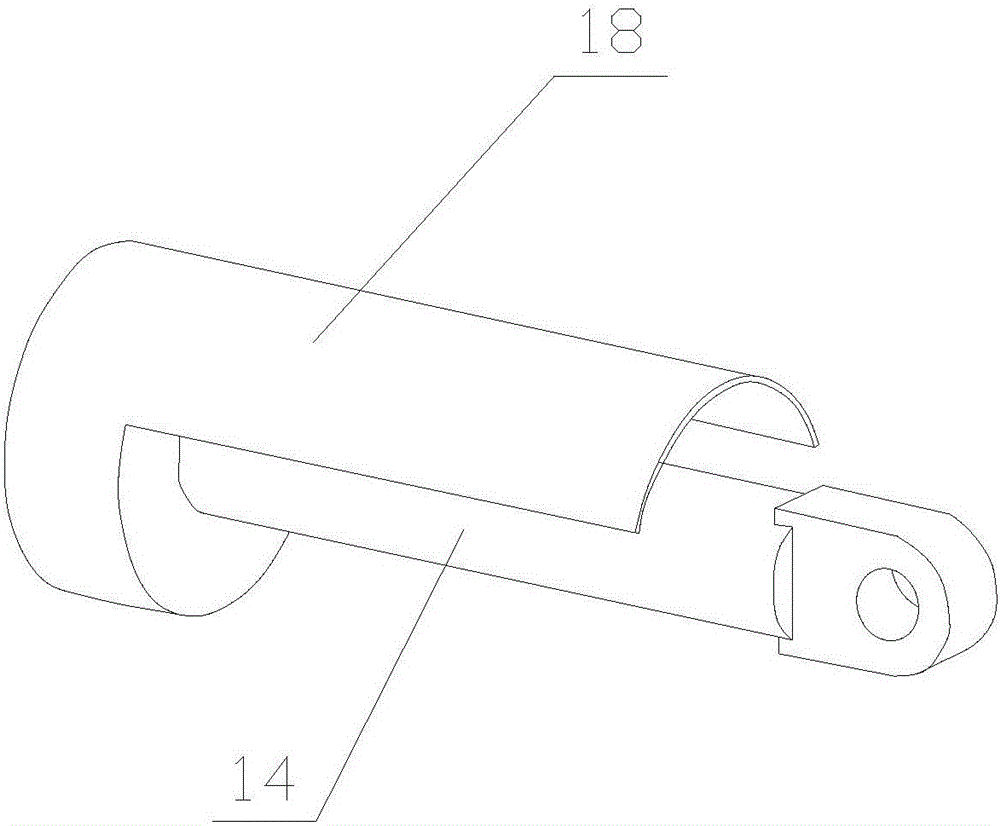

[0013] Such as figure 1 , 2 , 3, the present invention discloses a pellet machine, including extruding device, cutter device and driving device. The extruding device comprises a first bracket 11, an extruding barrel 12, a sieve plate 13 and a piston 14. The extruding barrel 12 is installed on the first support 11, and the front end of the extruding barrel 12 is equipped with a sieve plate 13 through a bolt, and the sieve plate A number of through holes 15 are evenly distributed on the 13, a feed inlet 16 is opened above the extrusion barrel 12, a feed hopper 17 is installed above the feed inlet 16, the piston 14 is located in the extrusion barrel 12, and the tail of the piston 14 is connected to the driving device , used to drive the piston 14 to reciprocate in the extrusion barrel 12. An arc-shaped baffle 18 is arranged on the piston 14 , and the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com