Air suction type self-cuttings-discharge system for (CFRP) carbon fiber-reinforced plastics machining

An air-breathing, self-draining technology, which is applied in the direction of metal processing equipment, manufacturing tools, boring machine/drilling machine parts, etc., can solve the problems of polluting the environment, affecting the health of workers, and not being able to directly absorb it, so as to avoid the effect of polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] specific implementation plan

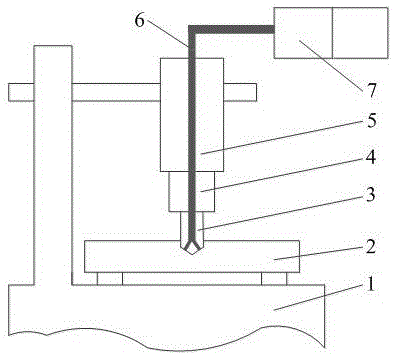

[0016] The suction type self-absorbing chip removal system for CFRP processing described in this design is characterized by mainly including: 1-machine tool, 2-workpiece, 3-drill bit, 4-knife handle, 5-spindle, 6-chip channel, 7-suction Gas / storage device, and 2-CFRP is fixed on 1-machine tool by fixture, 3-drill is connected to 4-tool holder, 4-tool holder is connected to 5-spindle, 5-spindle is connected to 1- The machine tool is connected, 6-chip channel is connected with 7-suction / storage device through 3-drill, 4-knife handle, 5-spindle.

[0017] Working principle: When 1-machine tool is started, 5-spindle is driven, 3-drill bit is drilling and 2-workpiece is processed, 7-suction / storage device will generate negative pressure to make the cutting powder produced by 3-drill bit processing pass through 3-drill bit, 4-knife handle, 5-spindle, 6-chip channel is transported to 7-suction / storage device to realize green processing of carbon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com