Semiconductor device manufacturing method

A manufacturing method and semiconductor technology, applied in the manufacture of microstructure devices, techniques for producing decorative surface effects, decorative art, etc., can solve the problems of easy gold residue in the gold layer and low uniformity of the undercut of the gold pattern block, etc. , to achieve the effect of avoiding gold residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

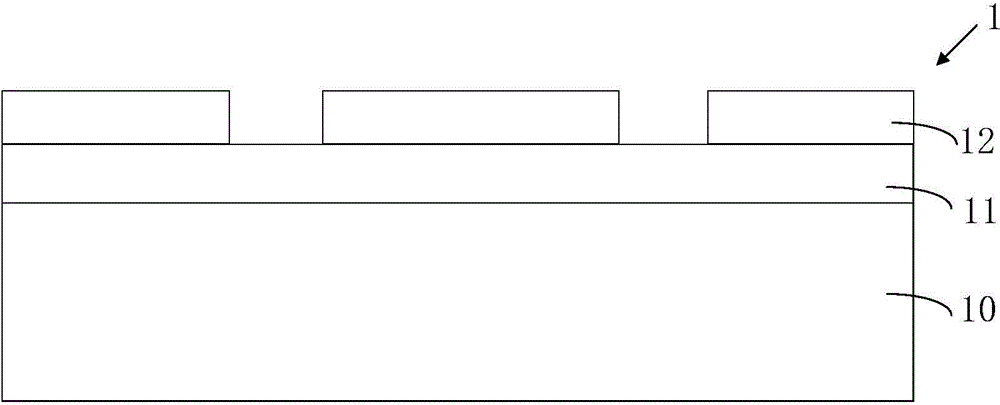

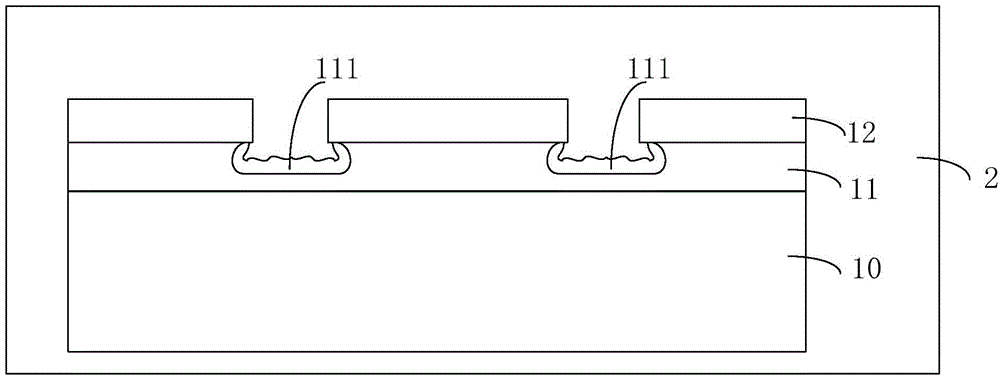

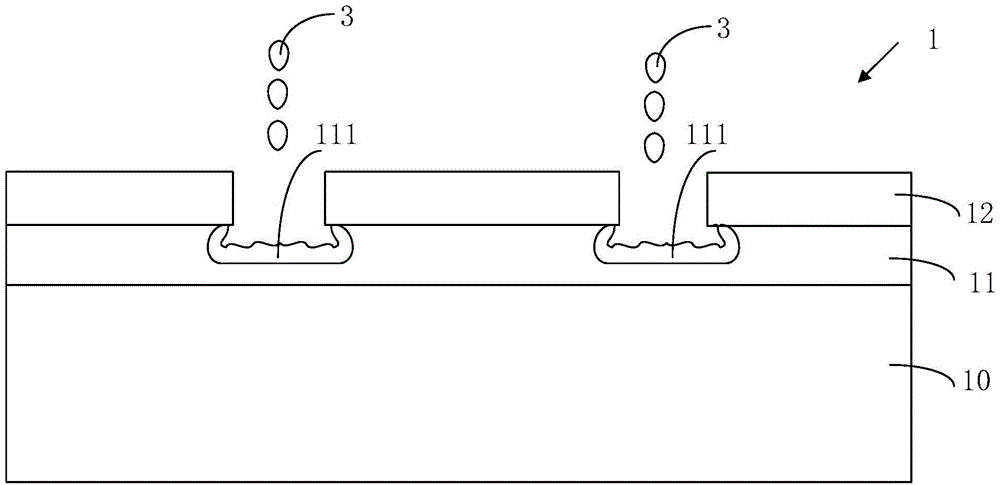

Embodiment Construction

[0024] As mentioned in the background art, there are some problems in the existing etching process of the gold layer. First, gold residue is prone to occur; second, the undercut amount is not uniform, that is, multiple etchings formed in the same batch The horizontal removal of gold pattern blocks varies, some are more, some are less. In view of the above-mentioned problems, the inventors have analyzed and found that the cause of the problem is: if the gold layer is corroded for a long time, for example, using KI and I 2 The above corrosion is isotropic corrosion. It will be found that as time goes by, more and more etching by-products accumulate on the surface of the gold layer. As the gold layer is covered by the etching by-products, it affects the gold The further corrosion rate of the layer and the amount of etching by-products coated in different areas are different. The gold layer in some areas may not be in contact with the etching solution. Therefore, on the one hand, it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com