A method and device for preparing nano-alumina from sulfur-containing flue gas

A nano-alumina and flue gas technology, applied in the direction of alumina/aluminum hydroxide, nanotechnology for materials and surface science, nanotechnology, etc., can solve the high production cost of nano-alumina and the pollution of sulfur-containing flue gas to the environment and other problems, to achieve the effect of uniform size, high purity and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

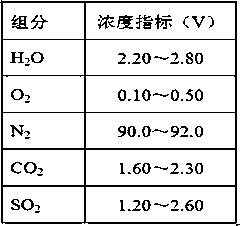

[0032] S-Zorb regeneration flue gas of an oil refinery, the gas volume is 1200Nm 3 / h, the temperature is 204°C, the pressure is 70kPa, and the composition of sulfur-containing flue gas is shown in Table 1.

[0033] Table 1 Composition of S-Zorb regeneration flue gas in a refinery

[0034]

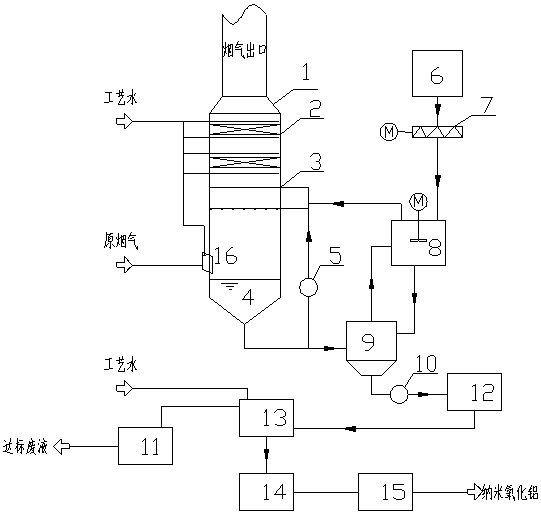

[0035] Adopt the present invention to attach figure 1 According to the method and device, the sulfur-containing flue gas first enters the quencher and uses process water to cool down. After cooling, the temperature is 45°C, and then enters the spray absorption section equipped with 2-layer spray equipment, and the absorption liquid contacts the flue gas countercurrently. Washing, the liquid-gas ratio is 6, the absorption liquid absorbs the sulfur dioxide in the flue gas, and the cleaner flue gas after passing through the demister is discharged from the flue at the top of the absorption tower.

[0036] After the sodium metaaluminate and the supernatant of the concentration tank are ful...

Embodiment 2

[0041] Take the same S-Zorb regeneration flue gas as in Example 1 as the processing object. Adopt the present invention to attach figure 1 According to the method and device, the sulfur-containing flue gas first enters the quencher and uses process water to cool down. After cooling, the temperature is 40°C, and then enters the spray absorption section equipped with 1-layer spray equipment, and the absorption liquid contacts the flue gas countercurrently. Washing, the liquid-to-gas ratio is 4, the absorption liquid absorbs the sulfur dioxide in the flue gas, and the cleaner flue gas after passing through the demister is discharged from the flue at the top of the absorption tower.

[0042] After the sodium metaaluminate and the supernatant of the concentration tank are fully stirred and mixed, a sodium metaaluminate solution with a mass concentration of 20% is prepared as a supplement to the absorption liquid and added to the absorption liquid circulation pipeline and the concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com