Preparation of zn by molten salt template method 1‑x mg x o Nanorod approach

A technology of zn1-xmgxo and nanorods, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., to achieve the effects of strong operability, high c-axis orientation, and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

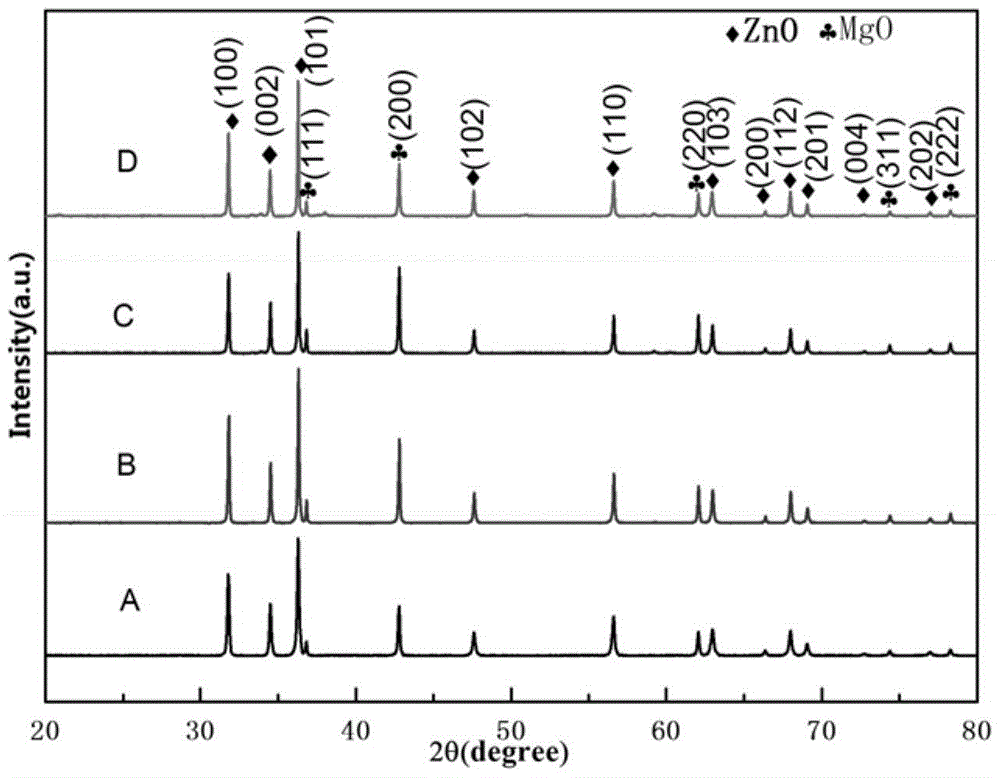

[0051] First, prepare 81g of ZnO nanorods, 0.5L of 2mol / L Mg(NO 3 ) 2 solution and oxalic acid, 81g of ZnO nanorods were added to 0.5L of 2mol / L Mg(NO 3 ) 2 solution, at the same time, oxalic acid is also added to the Mg(NO 3 ) 2 solution to obtain a mixed solution; here, oxalic acid may be in excess, so that by adding oxalic acid, Mg 2+ Complete reaction produces magnesium oxalate, at this moment, the pH value of mixed solution is 1. At this time, ZnO nanorods and Mg(NO 3 ) 2 Mg in solution 2+ The molar ratio is 1; in order to avoid precipitation of magnesium oxalate, here, ultrasonic dispersion is carried out on the mixed solution, and stirred.

[0052] Then, slowly inject 10wt% ammonia water into the mixed solution through a syringe to adjust the pH value to 7, thereby obtaining a precipitate; here, the addition rate of ammonia water is 0.1mL / s; then, dry the precipitate to Obtain the precursor; the precipitation is dried in an oven at 80°C for 24 hours;

[0053] ...

no. 2 example

[0055] First, prepare 121.5g of ZnO nanorods, 0.5L of 2mol / L Mg(NO 3 ) 2 solution and oxalic acid, 121.5g of ZnO nanorods were added to 0.5L of 2mol / L Mg(NO 3 ) 2 solution, at the same time, oxalic acid is also added to the Mg(NO 3 ) 2 solution to obtain a mixed solution; here, oxalic acid may be in excess, so that by adding oxalic acid, Mg 2+ Complete reaction produces magnesium oxalate, at this moment, the pH value of mixed solution is 6. At this time, ZnO nanorods and Mg(NO 3 ) 2 Mg in solution 2+ The molar ratio is 1.5; in order to avoid precipitation of magnesium oxalate, here, ultrasonic dispersion is carried out on the mixed solution, and stirred.

[0056] Then, slowly inject 10wt% ammonia water into the mixed solution through a syringe to adjust the pH value to 7, thereby obtaining a precipitate; here, the addition rate of ammonia water is 0.08mL / s; then, the precipitate is dried to obtain Obtain the precursor; the precipitation is dried in an oven at 80°C for...

no. 3 example

[0059] First, prepare 186.3g of ZnO nanorods, 0.5L of 2mol / L Mg(NO 3 ) 2 solution and oxalic acid, 186.3g of ZnO nanorods were added to 0.5L of 2mol / L Mg(NO 3 ) 2 solution, at the same time, oxalic acid is also added to the Mg(NO 3 ) 2 solution to obtain a mixed solution; here, oxalic acid may be in excess, so that by adding oxalic acid, Mg 2+ Complete reaction produces magnesium oxalate, at this moment, the pH value of mixed solution is 5. At this time, ZnO nanorods and Mg(NO 3 ) 2 Mg in solution 2+ The molar ratio of the mixture is 2.3; in order to avoid precipitation of magnesium oxalate, here, the mixed solution is ultrasonically dispersed and stirred.

[0060] Then, slowly inject 10wt% ammonia water into the mixed solution through a syringe to adjust the pH value to 8, thereby obtaining a precipitate; here, the addition rate of ammonia water is 0.1mL / s; then, dry the precipitate to Obtain the precursor; the precipitation is dried in an oven at 80°C for 24 hours; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com