High-throughput reactor suitable for biomass catalytic thermal cracking

A technology of catalytic pyrolysis and fluidized bed reactor, which is applied in the preparation of liquid hydrocarbon mixtures, educts, indirect heating and dry distillation, etc., and can solve the problem of undesigned high-flux reaction units and high-flux reactors that cannot meet the requirements of biomass Catalytic pyrolysis and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

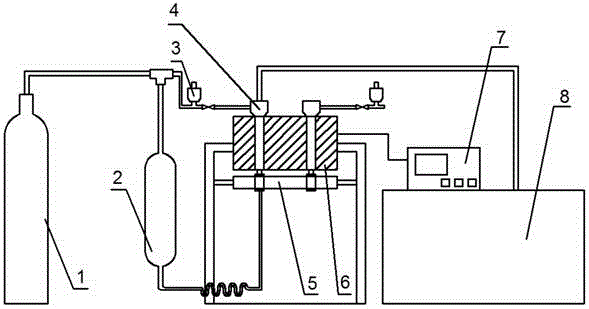

[0032] The high-throughput reactor suitable for catalytic pyrolysis of biomass described in this embodiment is characterized in that: the high-throughput reactor suitable for catalytic pyrolysis of biomass includes a preheating tank 2, a solid powder generator Material feeder 3, parallel fluidized bed reactor 4, multi-channel gas distributor 5, multi-channel heating furnace 6, temperature control system 7, high-resolution flight mass spectrometer 8;

[0033] Among them: the gas source 1 is connected to the preheating tank 2, and the preheating tank 2 is connected to the multi-channel heating furnace 6 through the multi-channel gas distributor 5; the parallel fluidized bed reactor 4 is installed in the multi-channel heating furnace 6; the temperature control system 7 are respectively connected with the multi-channel heating furnace 6 and the high-resolution flight mass spectrometer 8; the solid powder biomass feeder 3 is connected with the parallel fluidized bed reactor 4;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com