A kind of pour point depressant composition suitable for biodiesel-petrochemical diesel blended oil, preparation method and application thereof

A biodiesel, petrochemical diesel technology, applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of reducing the cold filter point and condensation point, the effect is not very obvious, achieve good technical effect, alleviate economic and economic and other problems. Effects of Environmental Stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

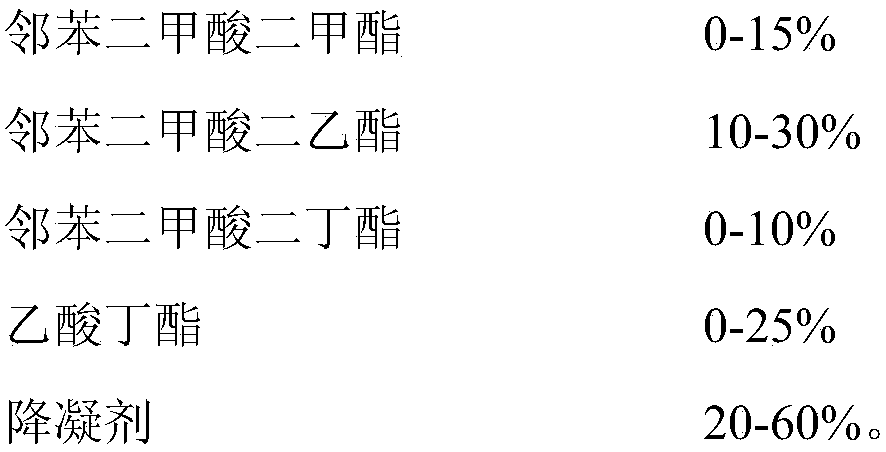

[0034] A kind of pour point depressant composition of biodiesel-petrochemical diesel blended oil, is mixed by dimethyl phthalate, diethyl phthalate, dibutyl phthalate, butyl acetate and pour point depressant Formed, calculated by mass percentage, its raw material composition and content are as follows:

[0035]

[0036] Wherein said pour point depressant is polymethacrylate pour point depressant 10-320.

[0037] The preparation method of the above-mentioned a kind of biodiesel-petrochemical diesel blended oil pour point depressant composition, the steps are as follows:

[0038] Under normal temperature and pressure, diethyl phthalate, dimethyl phthalate, dibutyl phthalate, butyl acetate and pour point depressant are mixed according to a predetermined mass percentage, and stirred at 40-50°C for 20 -25min, and ultrasonically dispersed for 25-30min, a kind of biodiesel-petrochemical diesel blended oil pour point depressant composition is obtained.

[0039] The above-mentione...

Embodiment 2

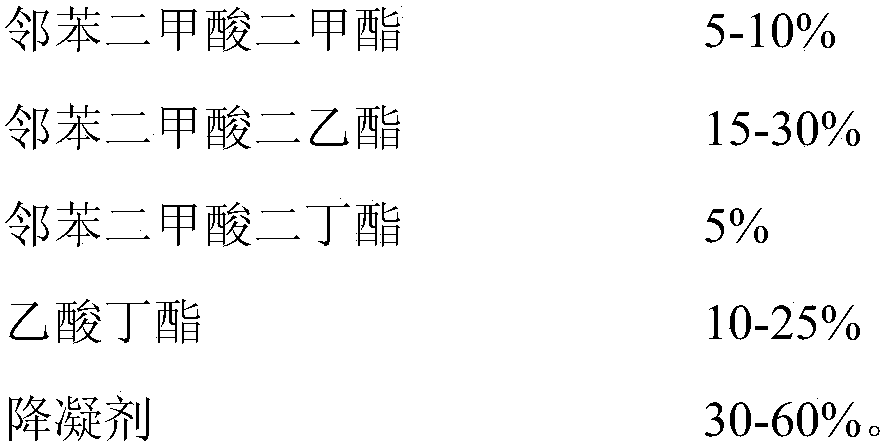

[0053] A kind of pour point depressant composition of biodiesel-petrochemical diesel blended oil, is mixed by dimethyl phthalate, diethyl phthalate, dibutyl phthalate, butyl acetate and pour point depressant Formed, calculated by mass percentage, its raw material composition and content are as follows:

[0054]

[0055] Wherein said pour point depressant is polymethacrylate pour point depressant 10-320.

[0056] The preparation method of the above-mentioned a kind of biodiesel-petrochemical diesel blended oil pour point depressant composition, the steps are as follows:

[0057] Under normal temperature and pressure, diethyl phthalate, dimethyl phthalate, dibutyl phthalate, butyl acetate and pour point depressant are mixed according to a predetermined mass percentage, and stirred at 40-50°C for 20 -25min, and ultrasonically dispersed for 25-30min, a kind of biodiesel-petrochemical diesel blended oil pour point depressant composition is obtained.

[0058] The above-mentione...

Embodiment 3

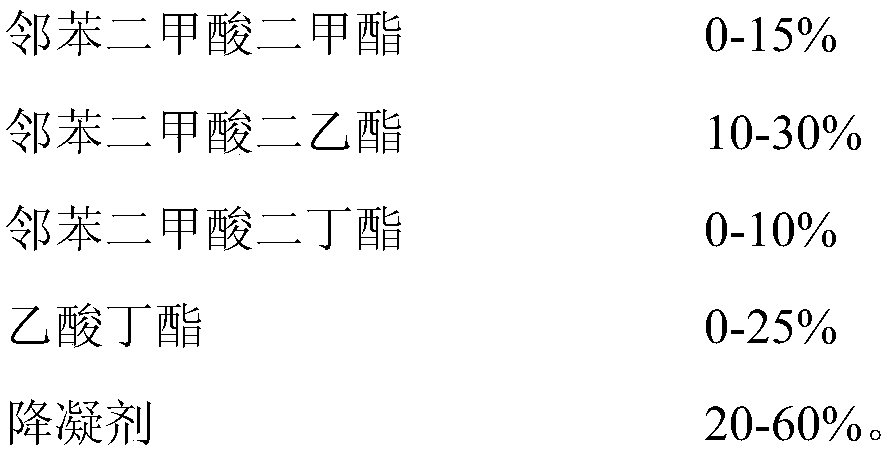

[0070] A kind of pour point depressant composition of biodiesel-petrochemical diesel blended oil, is mixed by dimethyl phthalate, diethyl phthalate, dibutyl phthalate, butyl acetate and pour point depressant Formed, calculated by mass percentage, its raw material composition and content are as follows:

[0071]

[0072] Wherein said pour point depressant is polymethacrylate pour point depressant 10-320.

[0073] The preparation method of the above-mentioned a kind of biodiesel-petrochemical diesel blended oil pour point depressant composition, the steps are as follows:

[0074] Under normal temperature and pressure, diethyl phthalate, dimethyl phthalate, dibutyl phthalate, butyl acetate and pour point depressant are mixed according to a predetermined mass percentage, and stirred at 40-50°C for 20 -25 minutes, and ultrasonically dispersed for 25-30 minutes to obtain a high-proportion biodiesel-petrochemical diesel blended oil pour point depressant composition.

[0075] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com