Anchoring structure for reinforcing T beam FRP

A technology of anchoring structure and FRP sheet, which is applied in the bridge and construction fields, can solve problems such as brittle failure of reinforcement devices, secondary damage of reinforced beams, secondary damage of reinforced beams, etc., to achieve easy assembly, good anchoring effect, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

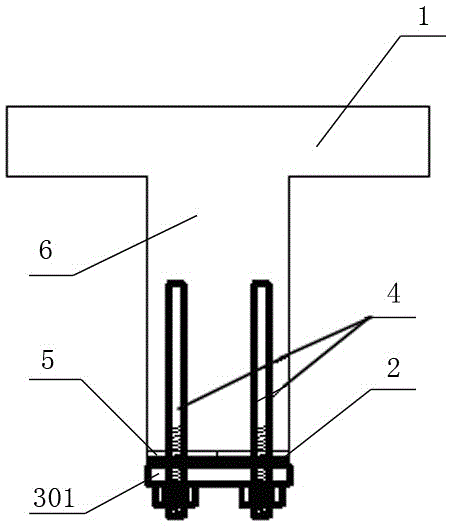

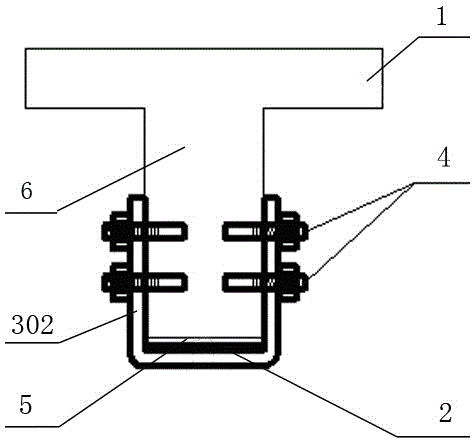

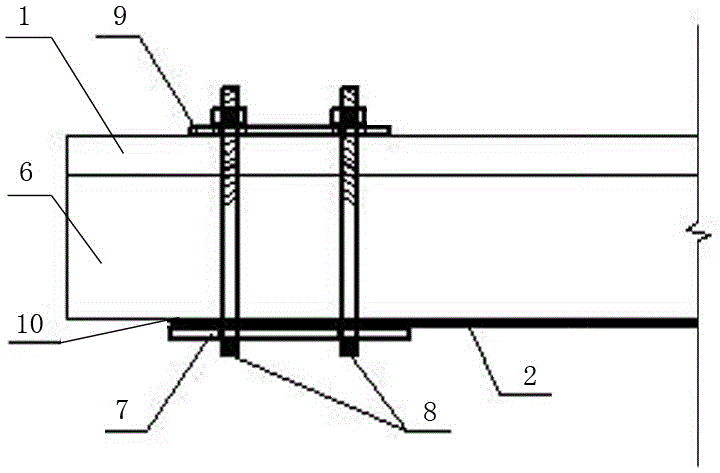

[0025] Such as image 3 , 4 , A kind of anchoring structure of the present invention that is used to strengthen T beam FRP shown in , 5, 6, comprises that the bottom of T beam beam rib 6 is provided with prestressed reinforcing material FRP sheet material 2, and its described FRP sheet material 2 lower end is provided with Pressing plate 7; there is also a carbon fiber cloth impregnated adhesive layer 10 belonging to A-grade epoxy resin glue between the FRP sheet 2 and the pressing plate 7. The pressing plate 7 is hooped by two U-shaped screws 8 with threads on the upper ends, and the The upper ends of the U-shaped screw rods 8 pass through the T-beam wing plate 1 and the upper edge top plate 9 respectively, and are fastened by spring washers and nuts. Both the pressure plate 7 and the upper edge top plate 9 are made of No. 45 steel plates, and the U-shaped screw 8 is made of R235 steel bars.

Embodiment 2

[0027] The present invention is an anchoring structure for reinforcing T-beam FRP, which comprises the reinforcement material FRP sheet 2 pasted on the bottom of the T-beam rib 6, and the lower end of the FRP sheet 2 is provided with a pressing plate 7; the FRP sheet 2 and the pressing plate 7 There is also an epoxy resin adhesive layer 10 between them, which is fastened by gaskets and bolts. The pressure plate 7 and the upper edge top plate 9 are all made of No. 20 steel plates. Others are the same as in Embodiment 1, and will not be repeated.

Embodiment 3

[0029] The present invention is an anchoring structure for reinforcing T-beam FRP, which includes reinforcing material FRP sheet 2 at the bottom of T-beam rib 6, and the pressure plate 7 and upper edge top plate 9 are all made of No. 20 steel plates. Others are the same as in Embodiment 1, and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com