Magnetic-field heat treatment method of nanocrystal magnetic core

A heat treatment method and nanocrystalline technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of high coercive force and iron loss of the magnetic core, large inductance attenuation, etc., to achieve coercive force and Reduced iron loss and excellent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] In this embodiment, the 20 μm thick amorphous strip is rolled and wound to obtain a ring magnetic core with a size of 20×14×10 mm.

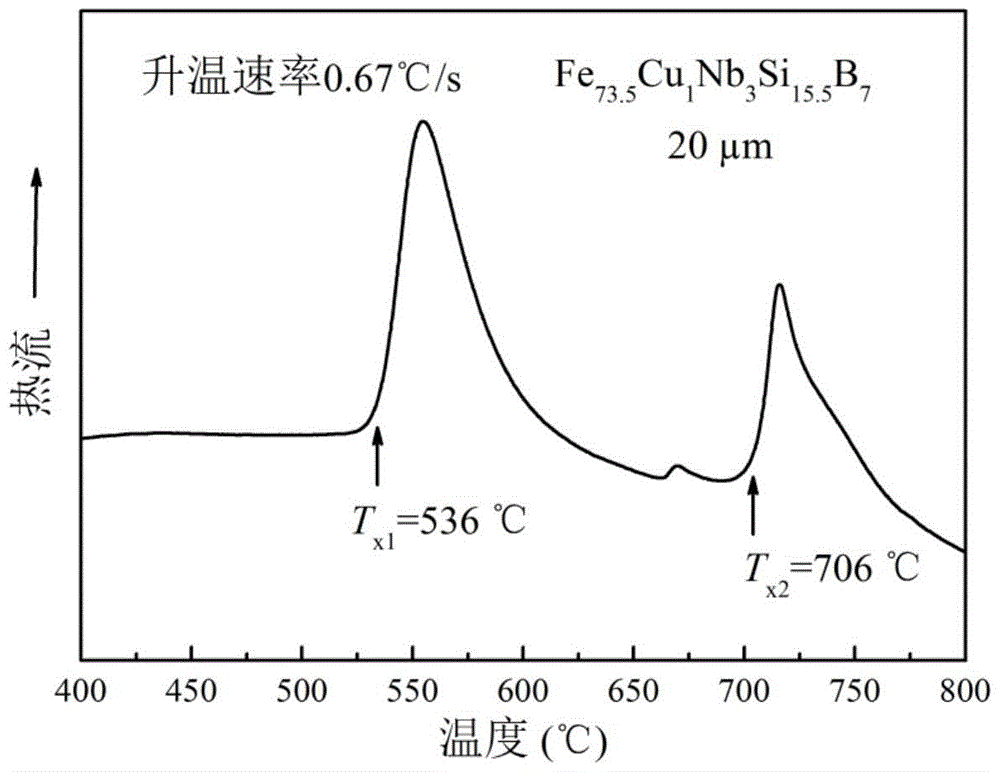

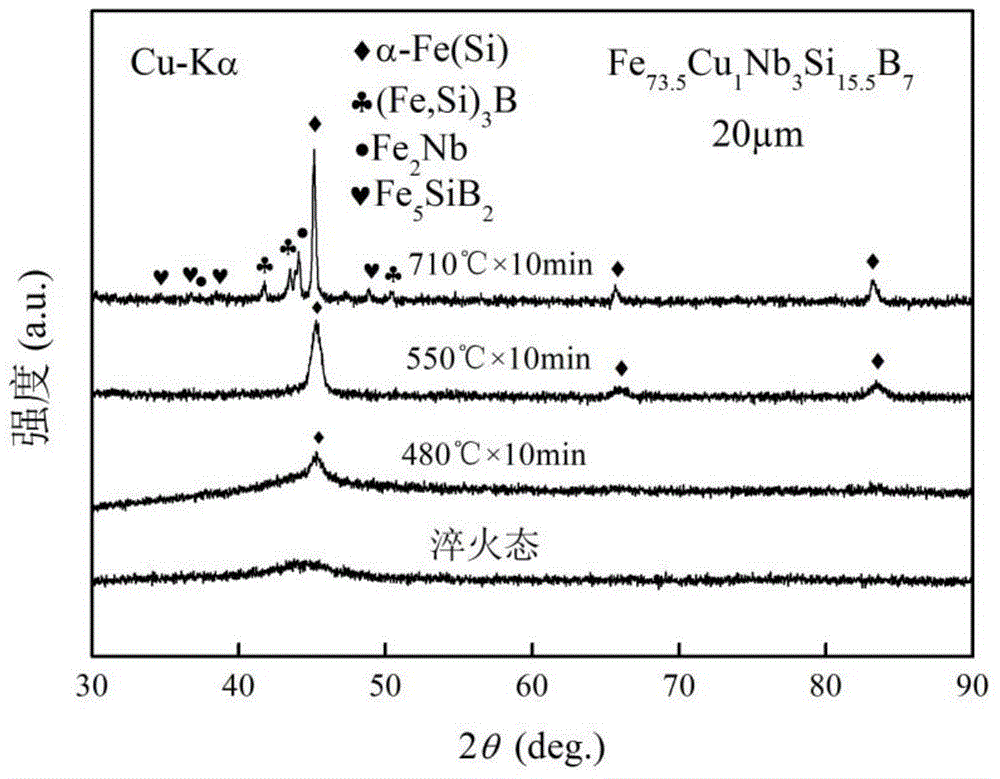

[0050] Step 1: Determine the general heat treatment process by analyzing the thermal properties and crystallization behavior of the alloy and combining the conditions in production practice.

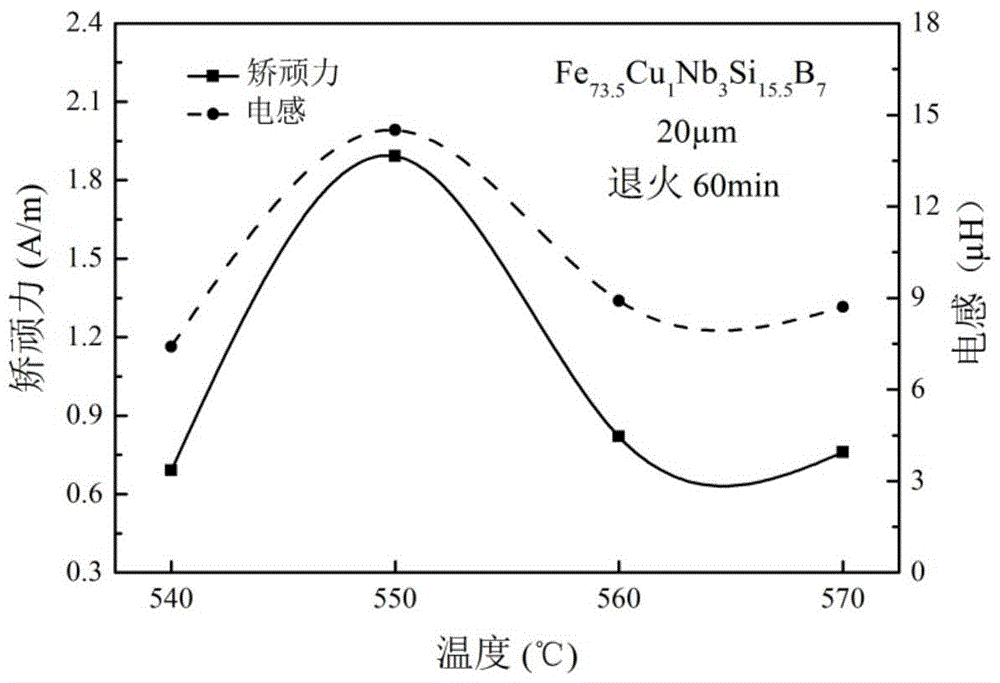

[0051] Step 2: After ordinary heat treatment, analyze and compare the inductance characteristics and soft magnetic characteristics of the magnetic core. At this time, the inductance value of the magnetic core is 14.5μH, and the coercive force of the magnetic core under this heat treatment condition is 1.9A / m, and the magnetic core is at 0.2T, 20kHz The iron loss under the condition is 2.2W / kg, and the iron loss under the condition of 0.5T and 20kHz is 10.8W / kg.

[0052] Step 3: Carry out magnetic field heat treatment in three different magnetization stages under common heat treatment conditions, and the magnetization current is 100A.

[0053] The fi...

Embodiment 2

[0074]In this embodiment, amorphous strips with thicknesses of 18 μm, 20 μm, 22 μm and 24 μm were rolled and wound to obtain a ring magnetic core with a size of 20×14×10 mm. Because the heat treatment process steps and performance change trends of magnetic cores with different strip thicknesses are completely consistent with Embodiment 1, for the purpose of brevity, the accompanying drawings are omitted and not fully given, but under the conditions of TF1 (magnetizing current 140A) magnetic field heat treatment The soft magnetic properties and inductance characteristics are given in detail.

[0075] After ordinary heat treatment, analyze and compare the inductance characteristics and soft magnetic properties of four kinds of magnetic cores with different thicknesses. At this time, the inductance value of the magnetic core is 10-16μH, and the coercive force is 1.9-2.0A / m, and the magnetic core is at 0.2T, 20kHz The iron loss under the condition is 1.7-2.2W / kg, and the iron loss...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coercivity | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

| Iron loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com