Welded joint structure of thick-walled large-diameter pipe and its welding construction method

A technology of welding joints and construction methods, which is applied in the direction of welding/welding/cutting items, welding equipment, manufacturing tools, etc., can solve the problems of high risk of reheating cracks, coarse grains, high technical difficulty, etc., and achieve reliability , the effect of preventing reheat cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

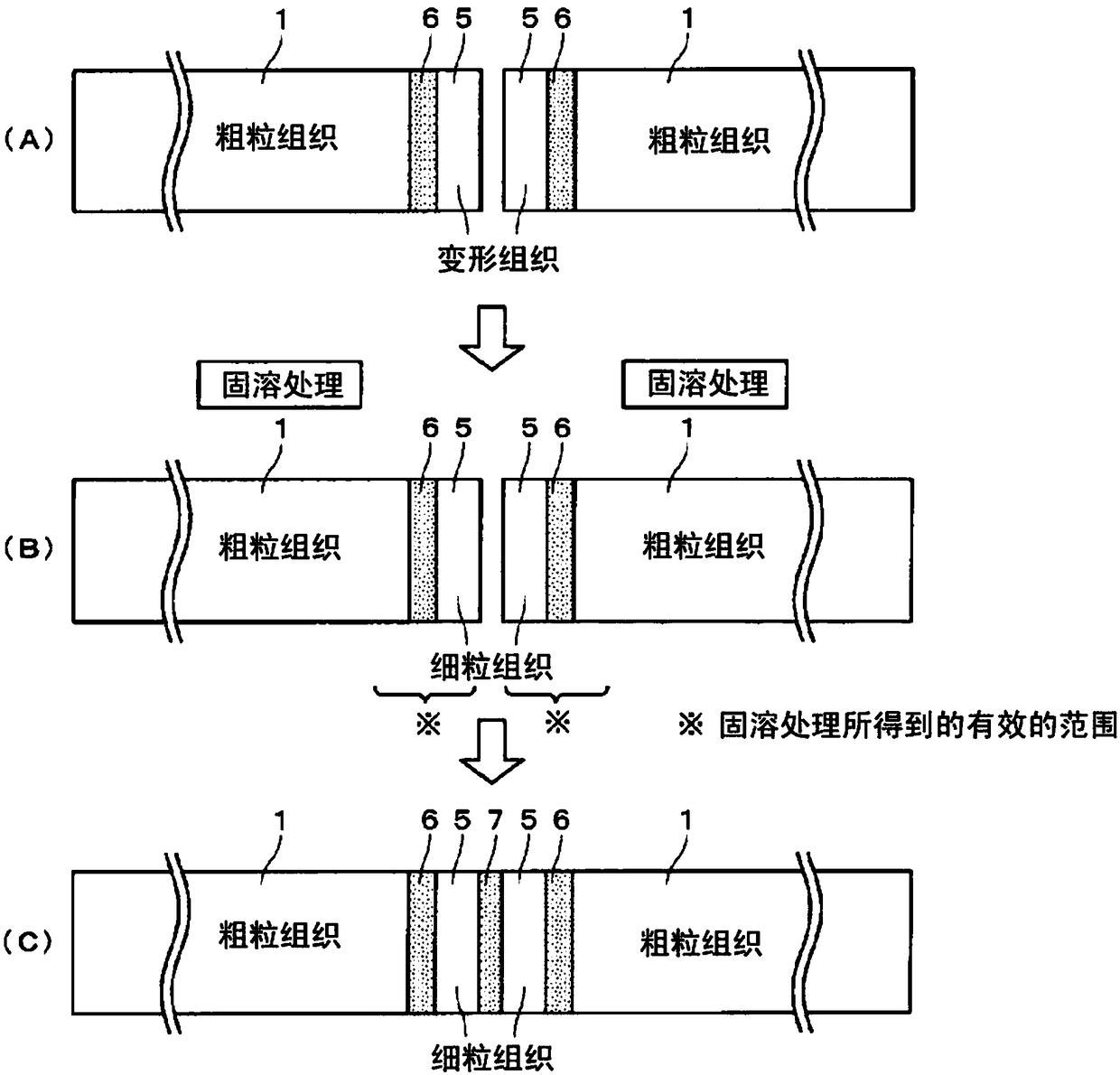

[0044] figure 1 In order to show the welding joint structure and welding construction method of the thick-walled large-diameter tube in the boiler, which is the main equipment in the next-generation ultra-supercritical pressure power generation equipment, and the welding construction method, from the tube welding part to the final welding A map of the construction status.

[0045] First, if figure 1 As shown in (A), a pair of thick-walled large-diameter tubes with a wall thickness of 20mm, a diameter of 165.2mm, and a length of 3m formed by a Ni-based alloy (Alloy617; 52Ni-22Cr-13Co-9Mo-Ti-1Al) 1, 1 Weld respectively intermediate members (short tubes) 5, 5 made by material manufacturers and made of the same material with a wall thickness of 20 mm, a diameter of 165.2 mm, and a length of 150 mm.

[0046] It should be noted that the aforementioned thick-walled and large-diameter pipe 1 is obtained from a steel pipe manufacturer among the material manufacturers as follows: ho...

Embodiment 2

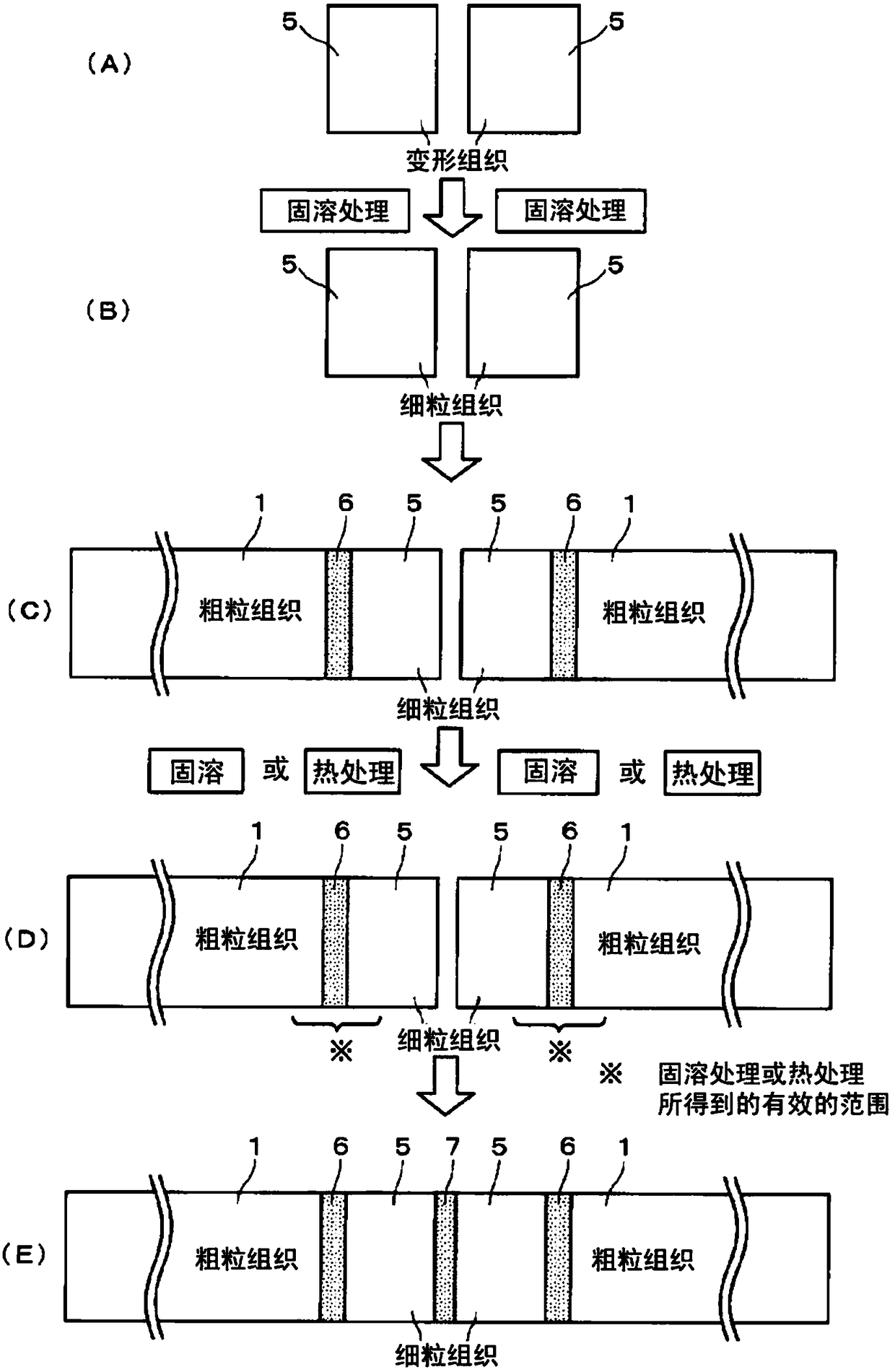

[0056] figure 2 In order to show the welding joint structure and welding construction method of the thick-walled large-diameter tube in the boiler, which is the main equipment of the next-generation ultra-supercritical pressure power generation equipment, in this embodiment, the construction of the pipe welding part until the final welding status diagram.

[0057] First, if figure 2 As shown in (A) and (C), a pair of thick-walled large-diameter tubes 1, 1 with a wall thickness of 20mm, a diameter of 165.2mm, and a length of 3m formed by a Ni-based alloy (Alloy617) (refer to figure 2 (C)) and an intermediate member 5 with a wall thickness of 20 mm, a diameter of 165.2 mm, and a length of 250 mm formed of the same material, are processed by hot forging or cold forging at a forging factory in the same manner as in Example 1 in order to improve the degree of processing and form a deformed structure. to make. First, the length and shape are formed by forging, and the inner di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com