Self-propelled air-conveying type orchard spraying machine

A sprayer, air-driven technology, applied in the field of self-propelled air-driven orchard sprayers, can solve the problems of low work efficiency, troublesome, and poor liquid deposition rate of leaves, so as to achieve high work efficiency, improve liquid deposition rate, good spray effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

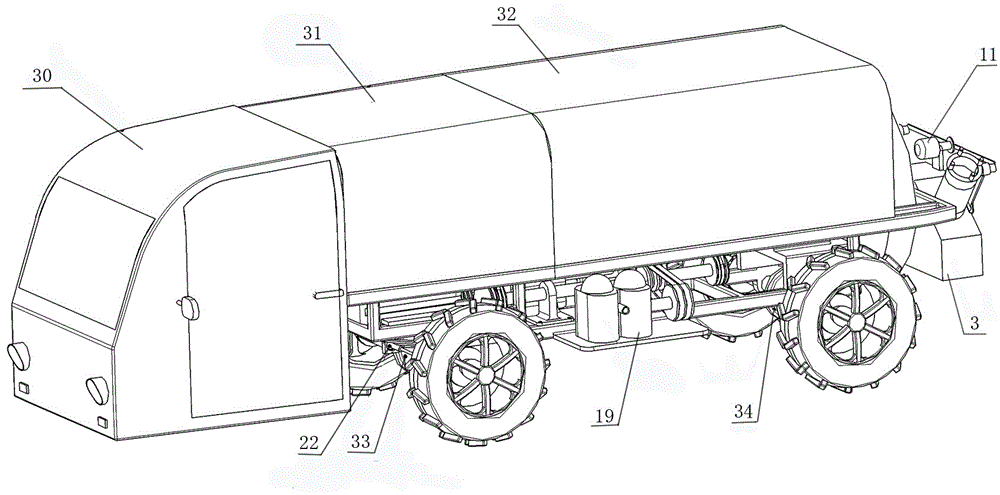

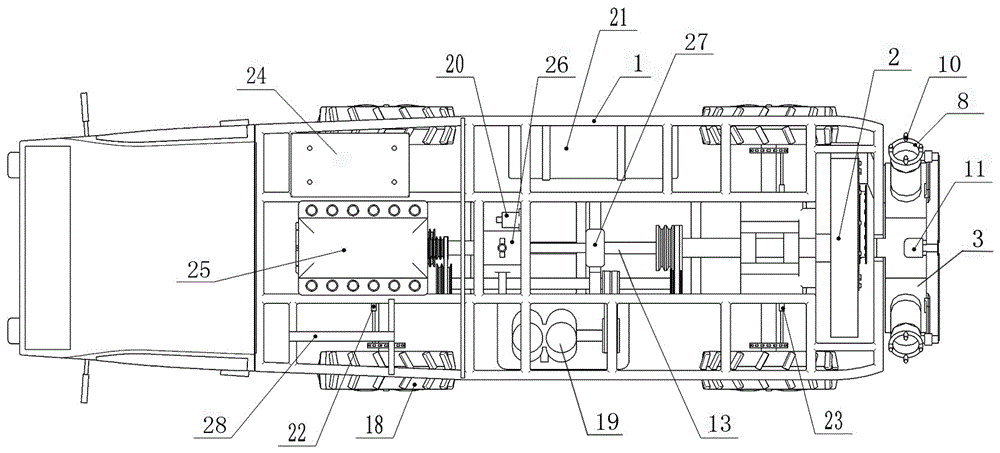

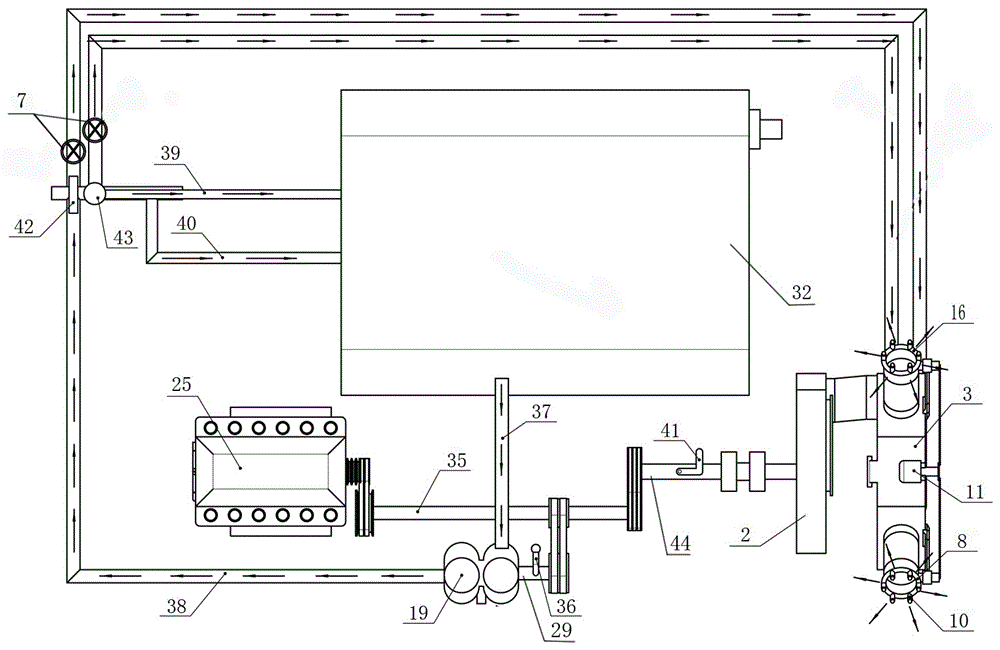

[0041] as attached Figure 1-7As shown, a self-propelled air-driven orchard sprayer includes a frame 1, a power system arranged on the frame 1, a spray system arranged at the rear of the frame 1, a transmission connected between the power system and the spray system system, the cockpit 30 arranged at the head of the frame 1, and the traveling wheels 18 arranged below the frame, the spray system includes a liquid medicine tank 32 arranged on the frame 1 to hold the liquid medicine, and a water inlet pipe 37 through a diaphragm pump. Diaphragm pump 19 communicated with liquid medicine tank 32, diaphragm pump outlet pipe 38 connected to the outlet of diaphragm pump 19, and a high-pressure spray mechanism connected to diaphragm pump outlet pipe 38 on the frame 1, the diaphragm pump 19. By accepting the control signal output by the adjustment control unit, the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com