Processing method of broadleaf holly leaf teabag

A processing method and a tea bag technology are applied in the processing field of Kuding tea tea bags, which can solve the problems of heavy bitterness of Kuding tea and difficulty in guaranteeing hygienic indicators, so as to maintain the original taste, high production efficiency and good taste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

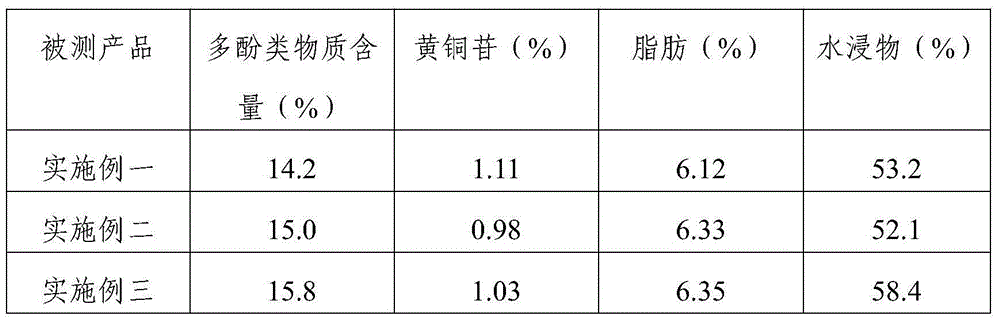

Examples

Embodiment 1

[0018] A kind of processing method of Kudingcha teabag, comprises the following steps:

[0019] (1) Withering: Pick the fresh leaves of Kudingcha with one bud and three leaves, spread it in the withering tank at normal temperature, the thickness of the spread leaves is 2cm, and the spread time is 16h, and the withered leaves with a moisture content of 63% are obtained ;

[0020] (2) Finishing: send the withered leaves into the finishing machine for circulation and finishing. The first finishing temperature is 180°C, and the finishing time is 3 minutes. After cooling, the second finishing is carried out. Carry out the third greening after cooling, the control temperature is 100°C, the greening time is 3min, and the green leaves are obtained;

[0021] (3) Drying: send the green leaves into the drier, and dry them at a temperature of 60°C to a moisture content of 6%, to obtain dried leaves;

[0022] (4) Pulverization: the dry leaves are sent into a pulverizer, pulverized with a...

Embodiment 2

[0024] A kind of processing method of Kudingcha teabag, comprises the following steps:

[0025] (1) Withering: Pick the fresh leaves of Kudingcha with one bud and two leaves, spread it in the withering tank at normal temperature, the thickness of the spread leaves is 2cm, and the spread time is 18h, and the withered leaves with a moisture content of 63% are obtained ;

[0026] (2) Finishing: Send the withered leaves into the finishing machine for circulation and finishing. The first finishing temperature is 200°C, and the finishing time is 4 minutes. After cooling, the second finishing is carried out. Carry out the third greening after cooling, the control temperature is 120° C., and the greening time is 4 minutes to obtain green leaves;

[0027] (3) Drying: Send the green leaves into the drier, and dry them at a temperature of 80°C to a moisture content of 4%, to obtain dried leaves;

[0028] (4) Pulverization: the dried leaves are sent into a pulverizer, pulverized with an...

Embodiment 3

[0030] A kind of processing method of Kudingcha teabag, comprises the following steps:

[0031] (1) Withering: Pick the fresh leaves of Kudingcha with one bud and two leaves, spread it in the withering tank at normal temperature, the thickness of the spread leaves is 2cm, and the spread time is 17h, and the withered leaves with a moisture content of 62% are obtained ;

[0032] (2) Finishing: Send the withered leaves into the finishing machine for circulation and finishing. The first finishing temperature is 190°C, and the finishing time is 3 minutes. After cooling, the second finishing is carried out. Carry out the third greening after cooling, the control temperature is 110° C., and the greening time is 3 minutes to obtain green leaves;

[0033] (3) Drying: send the green leaves into a drier, and dry them at a temperature of 70° C. to a moisture content of 5%. obtain dry leaves;

[0034] (4) Pulverization: the dried leaves are sent into a pulverizer, pulverized with a 90-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com