Low-concentration organic exhaust gas fluidization tower

A technology of organic waste gas and fluidized tower, which is applied in the direction of air quality improvement, chemical instruments and methods, and separation of dispersed particles, which can solve the problems of less application and achieve the effects of low operating cost, simple structure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

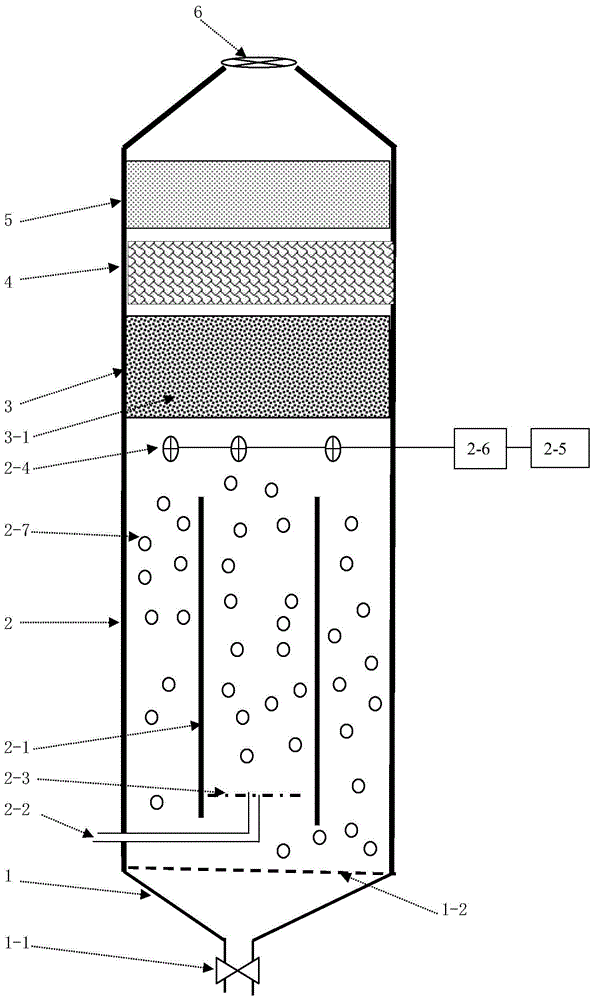

[0022] like figure 1 A low-concentration organic waste fluidization tower of the present invention is shown, from the bottom of the tower upwards, there are muddy water zone 1, fluidization zone 2, adsorption oxidation zone 3, dehumidification zone 4, activated carbon adsorption zone 5 and exhaust fan 6.

[0023] The muddy water area 1 is located at the bottom of the entire tower; the muddy water area 1 is designed as a conical structure to collect muddy water from the upper part, and the bottom of the conical structure is provided with a discharge valve 1-1, which is connected to the The sludge thickening tank outside the tower.

[0024] A separation plate 1-2 with holes is arranged between the muddy water zone 1 and the fluidized zone 2.

[0025] The fluidization zone 2 is provided with a fluidization cylinder 2-1, the fluidization cylinder 2-1 is a cylindrical cylindrical structure, located in the center of the fluidization zone 2, and the lower end opening of the fluidiza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com