Layered Microcrystalline Stone Tiles

A technology of microcrystalline stone and ceramic tiles, which is applied in the direction of layered products, glass/slag layered products, chemical instruments and methods, etc., can solve the problems of not being able to divide into layers, achieve better effects and increase visual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

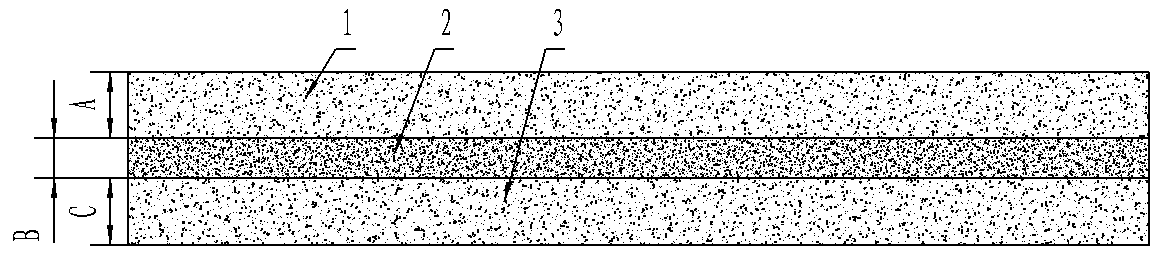

[0013] Such as figure 1 The layered microcrystalline stone tiles shown here include a microcrystalline stone slab body, and the microcrystalline stone slab body includes at least three layers of microcrystalline stone material layers stacked. Crystal material layer 1, the second layer of microcrystalline material layer 2, and the third layer of microcrystalline material layer 3 adopt the method of stacking multiple layers of microcrystalline material layers, so that the refractive index is different due to different crystallization at different times. Layers of microcrystalline stone materials are layered on top of each other to visually produce a layered effect.

[0014] The raw material of the first layer of microcrystalline stone material layer 1 includes the following components by weight: 60 parts of silicon dioxide, 20 parts of calcium carbonate, 6 parts of calcium oxide, 4 parts of zinc oxide, 2 parts of barium carbonate, and 3 parts of boron oxide.

[0015] The raw ma...

Embodiment 2

[0019] This layered microcrystalline stone tile includes a microcrystalline stone slab body, and the microcrystalline stone slab body includes at least three layers of microcrystalline stone material layers stacked on top of each other, here are five layers, and the first layer of microcrystalline stone material is in order from top to bottom layer, the second layer of microcrystalline stone material layer, the third layer of microcrystalline stone material layer, the fourth layer of microcrystalline stone material layer, and the fifth layer of microcrystalline stone material layer.

[0020] The raw materials of the first layer of microcrystalline stone material layer include the following components by weight: 70 parts of silicon dioxide, 16 parts of calcium carbonate, 10 parts of calcium oxide, 3 parts of zinc oxide, 1 part of barium carbonate, 2 parts of boron oxide, Aluminum 3 parts.

[0021] The raw materials of the second layer of microcrystalline stone material layer in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com