A kind of asphalt mixture for alleviating urban heat island effect and preparation method thereof

A technology of urban heat island effect and asphalt mixture, which is applied in the field of asphalt mixture, can solve the problems of high heat capacity of road materials, low solar reflectance, and environmental pollution, so as to reduce the dissipation of heat energy, reduce the overall temperature, and reduce heat Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

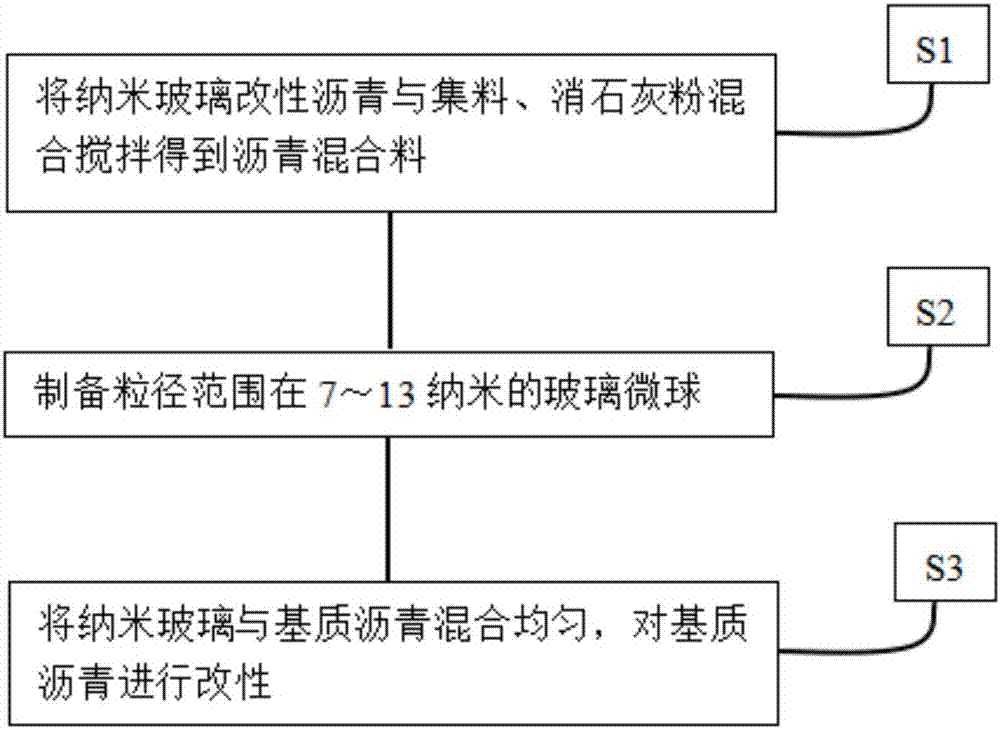

Method used

Image

Examples

Embodiment 1

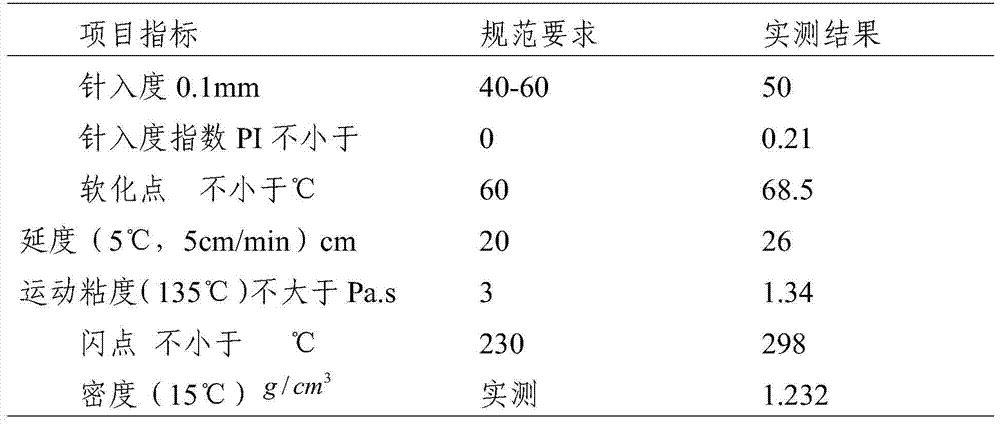

[0025] The asphalt mixture of this embodiment is formed by mixing 48g of modified asphalt, 0.95g of slaked lime powder and 951.05g of aggregate.

[0026] The modified asphalt of the present embodiment is by doping nano glass microspheres in the matrix asphalt, and utilizes the nano glass microspheres to modify the matrix asphalt, wherein the matrix asphalt adopts SK-70# matrix asphalt, and its various performance indicators (such as Penetration, ductility, softening point, etc.) should be tested to meet the requirements of the "Highway Engineering Aggregate Test Regulations" (JTG E42-2005), the base asphalt is 46.08g, accounting for 96% of the total modified asphalt. The amount of glass microspheres is 1.92g, accounting for 4% of the total amount of modified asphalt, and its particle size is 7-13nm.

[0027] The gradation of the above-mentioned aggregates satisfies: when passing through sieves of 26.5, 19, 16, 13.2, 9.5, 4.75, 2.36, and 0.075 mm respectively, the pass rates co...

Embodiment 2

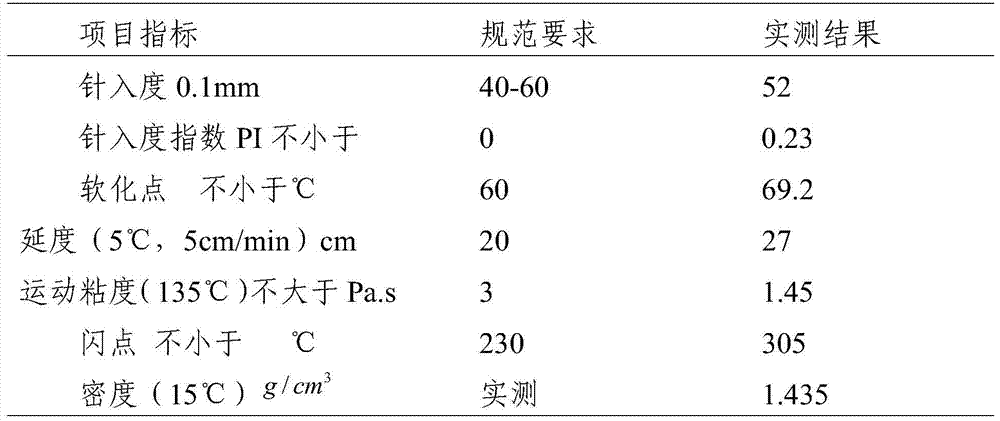

[0033] The change of this embodiment relative to the first embodiment is that the asphalt mixture is made by mixing 45g of modified asphalt, 0.9g of slaked lime powder and 952.6g of aggregate.

[0034] The modified asphalt of this embodiment is by doping nano-glass microspheres in the matrix asphalt, and utilizing nano-glass microspheres to modify the matrix asphalt, wherein the matrix asphalt is 43.65g, accounting for 97% of the total amount of modified asphalt, which It adopts SK-70# matrix asphalt, and its various performance indicators (such as penetration, ductility, softening point, etc.) The ball is 1.35g, accounting for 3% of the total amount of modified asphalt, and its particle size ranges from 7 to 13nm.

[0035] The gradation of the above-mentioned aggregates satisfies: when passing through sieves of 26.5, 19, 16, 13.2, 9.5, 4.75, 2.36, and 0.075 mm respectively, the pass rates correspond to 100%, 95%, 78%, 68%, 50%, 30%, 16%, 4%, which is basalt, its needle flake...

Embodiment 3

[0038] The change of this embodiment relative to the first embodiment is that the asphalt mixture is made by mixing 50 g of modified asphalt, 1 g of slaked lime powder and 949 g of aggregate.

[0039] The modified asphalt of this embodiment is by doping nano-glass microspheres in the matrix asphalt, and utilizing nano-glass microspheres to modify the matrix asphalt, wherein the matrix asphalt is 47.5g, accounting for 95% of the total amount of modified asphalt. Use SK-70# base asphalt. The amount of glass microspheres is 2.5g, accounting for 5% of the total amount of modified asphalt, and the particle size range is 8-11nm.

[0040] The gradation of the above-mentioned aggregates satisfies: when passing through sieves of 26.5, 19, 16, 13.2, 9.5, 4.75, 2.36, and 0.075 mm respectively, the pass rates correspond to 100%, 97%, 85%, 74%, 54%, 35%, 20%, and 6%, which are basalts, whose needle flake content ≤ 10%, crushing value ≤ 23%, Los Angeles abrasion loss ≤ 24%, should be teste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com