Surfactant fracturing fluid suitable for ocean high-temperature oil and gas reservoir fracturing and preparation method

A technology for surfactants and oil and gas reservoirs, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of accelerated construction progress, complex construction procedures, slow construction progress, etc., to reduce damage and excellent sand-carrying performance , The effect of simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a method for preparing a surfactant fracturing fluid suitable for fracturing of marine high-temperature oil and gas reservoirs, including the following steps:

[0031] Step 1, taking a formula amount of 1% micelle regulator, 2% micelle accelerator and 1% organic breaker and mixing with seawater;

[0032] Step 2: Take 5% surfactant in formula and add it to the above seawater and stir rapidly to form high temperature seawater-based surfactant fracturing fluid.

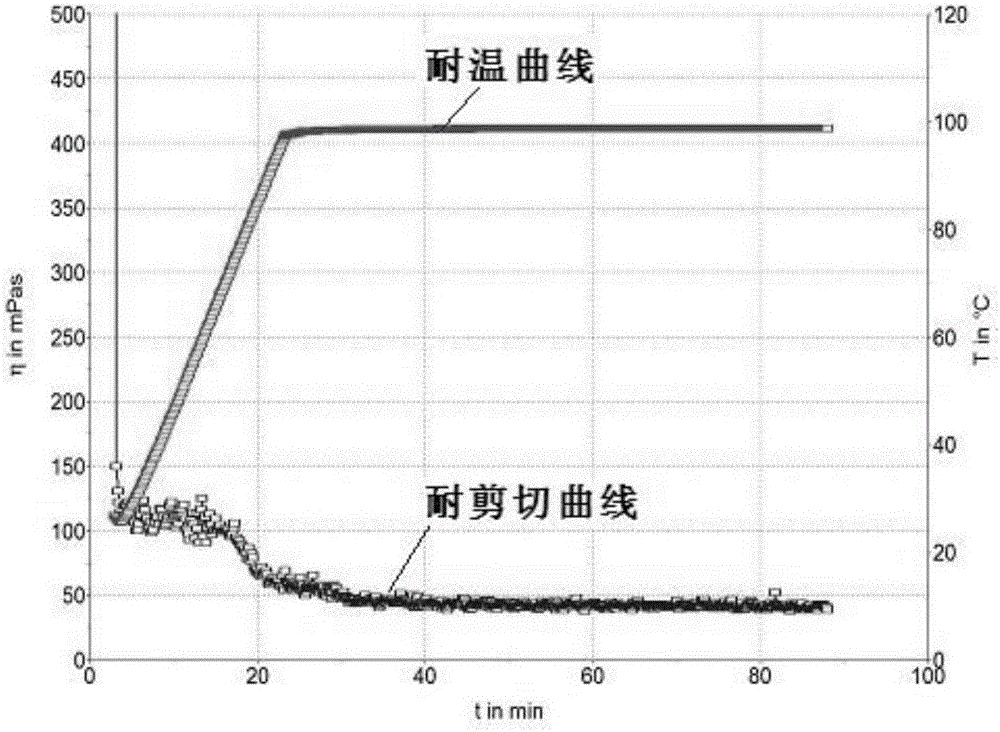

[0033] Add 5% surfactant, 2% micelle regulator and 1% micelle accelerator to seawater, and form seawater-based fracturing fluid under rapid stirring. The fracturing fluid has good temperature and shear resistance, and can be -1 Under continuous shear for 90 minutes, the viscosity remains above 30mPa.s, and its rheological curve is as follows figure 1 shown.

[0034] Add 1% organic gel breaker, and completely break the gel and hydrate under the static condition of 100°C for 1 hour.

Embodiment 2

[0036] This embodiment provides a method for preparing a surfactant fracturing fluid suitable for fracturing of marine high-temperature oil and gas reservoirs, including the following steps:

[0037] In step 1, take a formula amount of 2% micelle regulator, 3% micelle accelerator and 2% organic breaker and mix with seawater;

[0038] Step 2: Take 7% surfactant and add it to the above seawater and stir rapidly to form high-temperature seawater-based surfactant fracturing fluid.

[0039] Indoor test of temperature and shear resistance of surfactant fracturing fluid:

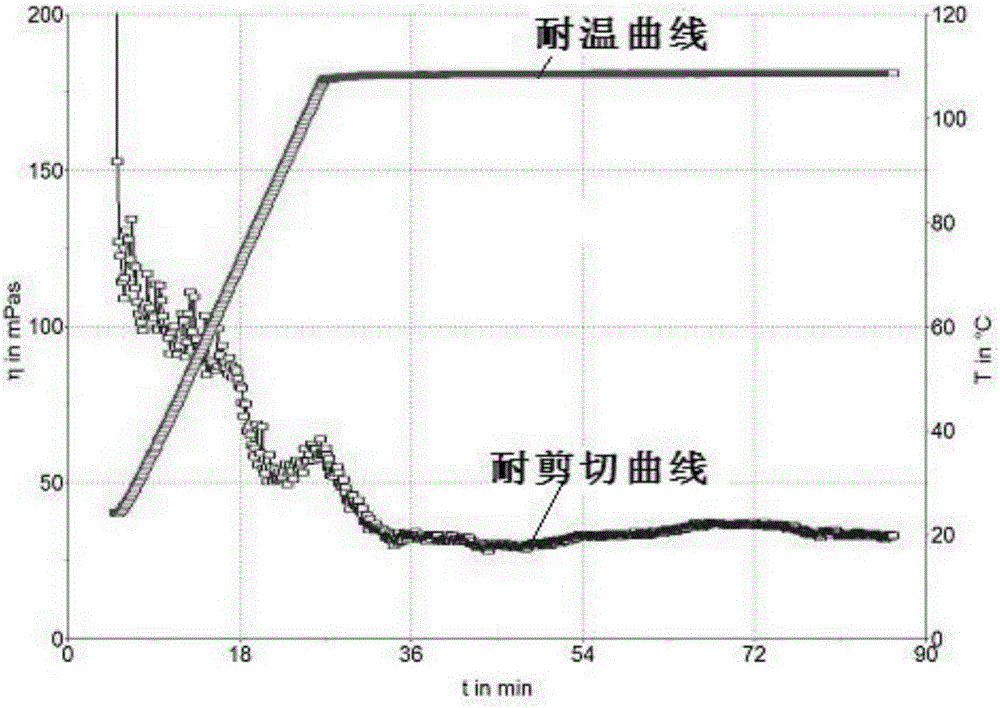

[0040] Add 7% surfactant, 3% micelle regulator and 2% micelle accelerator to seawater, and form seawater-based fracturing fluid under rapid stirring. The fracturing fluid has good heat resistance and shear resistance. -1 Under continuous shear for 90 minutes, the viscosity remains above 30mPa.s, and its rheological curve is as follows figure 2 shown.

[0041] Add 2% organic gel breaker, and completely break th...

Embodiment 3

[0043] This embodiment provides a method for preparing a surfactant fracturing fluid suitable for fracturing of marine high-temperature oil and gas reservoirs, including the following steps:

[0044] In step 1, take a formula amount of 3% micelle regulator, 4% micelle accelerator and 2% organic breaker and mix with seawater;

[0045] In step 2, take 8% surfactant and add it to the above seawater and stir rapidly to form a high-temperature seawater-based surfactant fracturing fluid.

[0046] Indoor test of temperature and shear resistance of surfactant fracturing fluid:

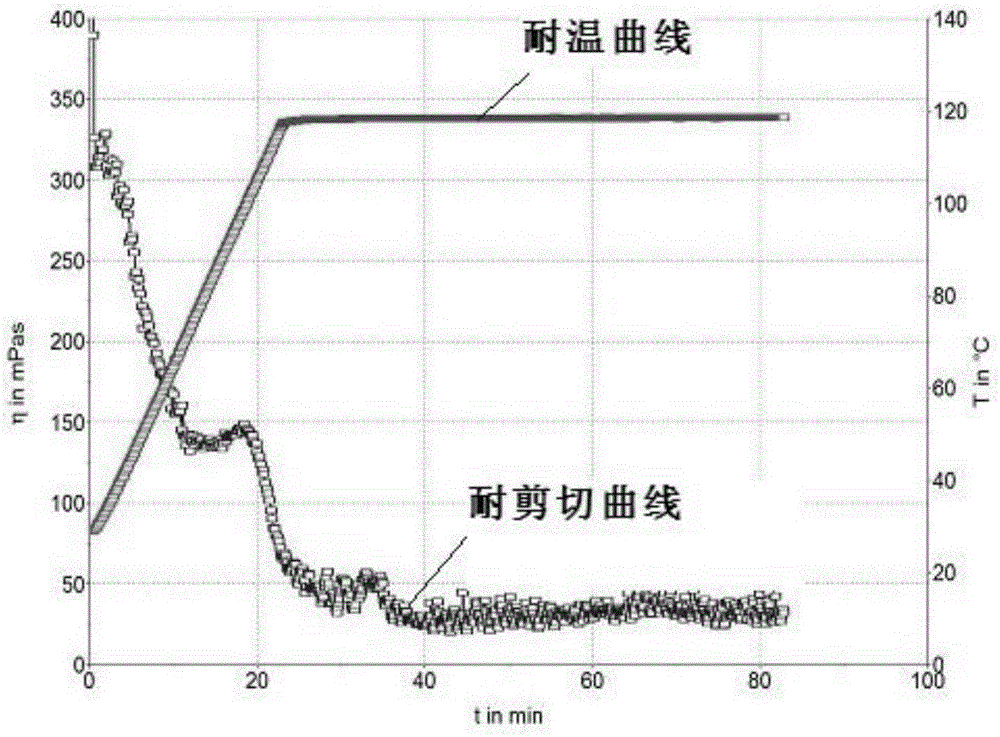

[0047]Add 8% surfactant, 3% micelle regulator and 4% micelle accelerator to seawater, and form seawater-based fracturing fluid under rapid stirring. The fracturing fluid has good temperature and shear resistance. -1 Under continuous shear for 90 minutes, the viscosity remains above 30mPa.s, and its rheological curve is as follows image 3 shown.

[0048] Add 2% organic gel breaker, and completely break the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com