Cracking method of waste plastic

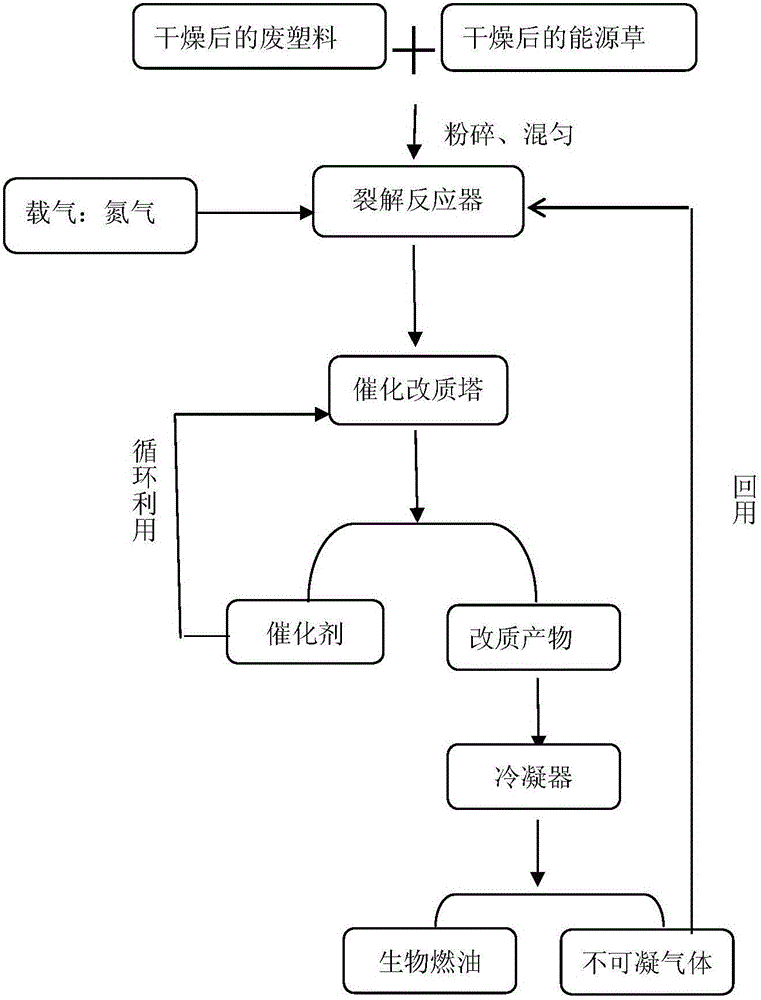

A technology of waste plastics and pyrolysis reaction, which is applied in the preparation of liquid hydrocarbon mixtures, the petroleum industry, and the treatment of hydrocarbon oils. It can solve the problems of low conversion rate of energy grass and low utilization of cellulose acetate resources, and reduce white pollution. problems, achieve efficient and clean utilization, and reduce dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Weigh 5kg Juneng grass, dry it at 100°C for 0.5h before use, weigh 3kg of cellulose acetate waste plastic and 2kg of PE waste plastic at the same time, dry it at 100°C for 0.5h before use, after pulverization and mixing , preheated to 100°C, kept warm for 1 hour, placed in a pyrolysis reactor for co-thermal cracking reaction, passed carrier gas nitrogen, the temperature rose to 450°C, kept warm for 4 hours, while the pyrolysis reaction was proceeding, the gaseous products entered the catalyst The catalytic reforming tower, the catalyst is the HBeta molecular sieve after Zn modification, the amount of the catalyst is 1% of the raw material weight, which is 0.1kg, the remaining catalyst in the catalytic reforming tower is returned to the catalytic reforming tower for recycling, and the non-condensable gas Return to the cracking reactor again for reuse, and finally, separate the liquid products to obtain biofuel products such as propylene, furfural, butane, etc., with an oi...

Embodiment 2

[0038] Weigh 3kg Juneng grass, dry it at 100°C for 0.5h, and then use it. At the same time, weigh 5kg of cellulose acetate plastic and 2kg of PE waste plastic, dry it at 100°C for 0.5h, and then use it. After pulverizing and mixing, Preheat to 100°C, keep it warm for 1 hour, put it in a pyrolysis reactor for co-thermal cracking reaction, pass the carrier gas nitrogen, the temperature rises to 500°C, keep it warm for 4 hours, while the pyrolysis reaction is going on, the gaseous product enters the reactor with catalyst Catalytic reforming tower, catalyst is HBeta molecular sieve after Zn modification, and the amount of catalyst is 2% of raw material weight, is 0.2kg, and the remaining catalyst in catalytic reforming tower returns catalytic reforming tower to recycle, and noncondensable gas is again Return to the cracking reactor for reuse. Finally, the liquid product is separated to obtain bio-fuel products such as propylene, furfural and butane. The oil yield is 35%, and it is ...

Embodiment 3

[0040] Weigh 3 kg of Jujuncao and 2 kg of Junengcao, dry at 100°C for 0.75h and set aside, weigh 3kg of cellulose acetate plastic and 2kg of PE waste plastic, dry at 100°C for 0.5h, set aside for use, after powder Purely mix, preheat to 120°C, keep warm for 1 hour, place it in a pyrolysis reactor for co-thermal cracking reaction, pass carrier gas nitrogen, the temperature rises to 550°C, keep warm for 4 hours, while the pyrolysis reaction is going on, the gaseous products enter Add the catalytic reforming tower of catalyst, catalyst is the HBeta molecular sieve after Fe modification, and the amount of catalyst is 1% of raw material weight, is 0.1kg, and the remaining catalyst in the catalytic reforming tower returns catalytic reforming tower to recycle, The non-condensable gas is returned to the pyrolysis reactor for reuse. Finally, the liquid product is separated to obtain bio-fuel products such as propylene, furfural, butane, etc., and the oil yield is 35%. After fractional d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com