High-elasticity copper-chromium-zirconium alloy and machining process thereof

A processing technology, copper-chromium-zirconium technology, applied in high-conductivity copper-chromium-zirconium alloy and its processing technology, high-elasticity copper-chromium-zirconium alloy, high-elasticity field, can solve the problem of rapid strength decline, low elastic properties of copper-chromium-zirconium alloy, copper-chromium-zirconium alloy Research on the influence of the strength and electrical conductivity of chromium-zirconium alloys to achieve the effect of high elasticity, high conductivity and improving the strength of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

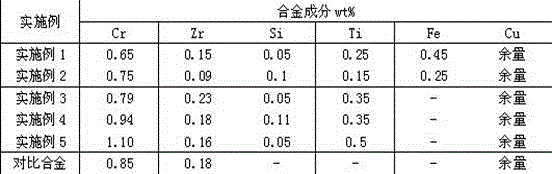

[0032] a Continuous casting: Melting is carried out in a horizontal continuous casting furnace. The order of adding the alloy is: first add Cu, after melting, add a covering agent (flaky graphite) and keep it warm for 5-10 minutes, after fully degassing and removing impurities, then add the master alloy of Cr, Zr, Si, Ti and Fe elements, Among them, Cr, Si, and Fe master alloys are added first, and the temperature of the melt in the furnace is kept at 1300°C. After melting, the furnace temperature is lowered to 1250°C, and then Zr and Ti master alloys are added. After holding the heat for 20 minutes, measure the alloy composition in the furnace, and adjust the furnace temperature to the continuous casting temperature of 1250°C after reaching the standard. The alloy composition is controlled by Example 1 in Table 1.

[0033] b Solid solution: The continuous casting rod is subjected to solution treatment, the temperature of solution treatment is 950°C, and the time is 5 hours. ...

Embodiment 2

[0039] a Continuous casting: Melting is carried out in a power frequency horizontal continuous casting furnace. The order of adding the alloy is: first add Cu, after melting, add a covering agent (flaky graphite) and keep it warm for 5-10 minutes, after fully degassing and removing impurities, then add the master alloy of Cr, Zr, Si, Ti and Fe elements, Among them, Cr, Si, and Fe master alloys are added first, and the temperature of the melt in the furnace is kept at 1300°C. After melting, the furnace temperature is lowered to 1250°C, and then Zr and Ti master alloys are added. After holding the heat for 20 minutes, measure the alloy composition in the furnace, and adjust the furnace temperature to the continuous casting temperature of 1250°C after reaching the standard. The alloy composition is controlled by Example 2 in Table 1.

[0040] b Solid solution: The continuous casting rod is subjected to solution treatment, the temperature of solution treatment is 950°C, and the t...

Embodiment 3

[0046] a Continuous casting: Melting is carried out in a power frequency horizontal continuous casting furnace. The order of adding the alloy is: first add Cu, after melting, add a covering agent (flaky graphite) and keep it warm for 5-10 minutes, after fully degassing and removing impurities, then add an intermediate alloy of Cr, Zr, Si and Ti elements, of which Cr Add Zr and Ti master alloys first, keep the melt temperature in the furnace at 1300°C, lower the furnace temperature to 1250°C after melting, and then add Zr and Ti master alloys. After holding the heat for 20 minutes, measure the alloy composition in the furnace, and adjust the furnace temperature to the continuous casting temperature of 1250°C after reaching the standard. The alloy composition is controlled by Example 3 in Table 1.

[0047] b Solid solution: The continuous casting rod is subjected to solution treatment, the temperature of solution treatment is 950°C, and the time is 4 hours.

[0048] c rolling:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com