A solar collector with high corrosion resistance

A technology of solar heat collectors and heat collecting tubes, applied in the field of solar energy, can solve the problems of insufficient corrosion resistance and reduced service life of heat collecting tubes, achieve optimal heat collecting effect and flow resistance, improve service life, and increase corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

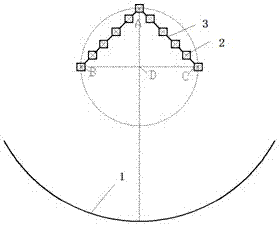

[0033] figure 1 A solar heat collector is shown, the heat collector includes a heat collecting tube 2, a reflector 1 and a heat collecting plate 3, and two adjacent heat collecting tubes 2 are connected through the heat collecting plate 3, so that multiple collectors A tube sheet structure is formed between the heat pipe 2 and the adjacent heat collecting plate 3; the solar heat collector system includes two tube sheet structures, and a certain angle is formed between the two tube sheet structures, and the included angle The direction is opposite to the bending direction of the arc structure of the reflector, and the focal point D of the reflector 1 is located between the angles formed by the tube-sheet structure.

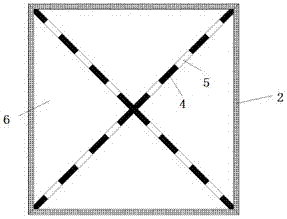

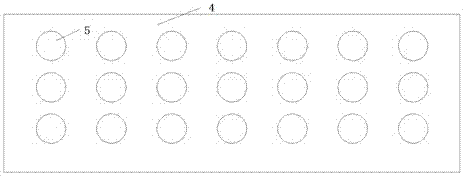

[0034] As an improvement, the cross-section of the heat collecting tube 2 is rectangular, and the heat collecting plate 3 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com