Comprehensive performance evaluation method for conductive slurry of lithium ion battery

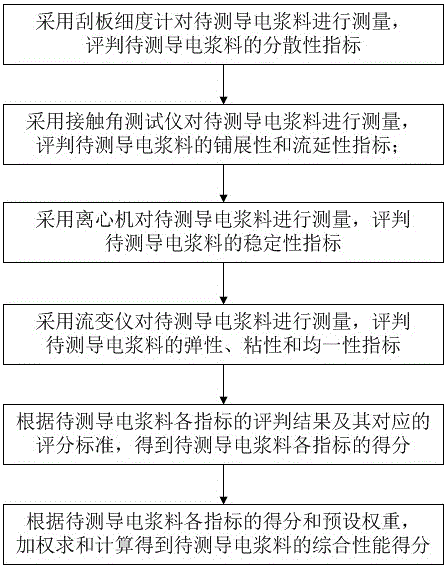

A comprehensive performance evaluation, lithium-ion battery technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of slurry stability, poor slurry stability, and evaluation of slurry performance, etc., to achieve practical Strong, reliable, and reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh FSN-1, hard carbon, SP, CMC and SBR, the mass percentage is 57:6:1:1:3, use H 2 O was used as a dispersing solvent, and was dispersed and stirred at high speed for 5 hours using a vacuum mixing equipment for conductive paste according to the process requirements, which was recorded as conductive paste a. First use two centrifuge tubes to take 30ml of conductive paste a for centrifugation to measure the stability of conductive paste a; then take an appropriate amount of conductive paste a for particle size and dispersion test, contact angle test, solid content and shear rate - Viscosity Change and Shear - Modulus Change Tests.

Embodiment 2

[0033] Weigh MCMB, hard carbon, SP, CMC and SBR, the mass percentage is 50:13:1:1:3, use H 2 O was used as a dispersing solvent, and was dispersed and stirred at high speed for 5 hours using a vacuum mixing equipment for conductive paste according to the process requirements, which was recorded as conductive paste b. First use two centrifuge tubes to take 30ml of conductive paste b for centrifugation to measure the stability of conductive paste b; then take an appropriate amount of conductive paste b for particle size and dispersion test, contact angle test, solid content and shear rate - Viscosity Change and Shear - Modulus Change Tests.

Embodiment 3

[0035] Weigh soft carbon, hard carbon, SP, CMC and SBR, the mass percentage is 50:13:1:1:3, use H 2 O was used as a dispersing solvent, and was dispersed and stirred at high speed for 5 hours using a vacuum mixing equipment for conductive paste according to the process requirements, which was recorded as conductive paste c. First use two centrifuge tubes to take 30ml of conductive paste c for centrifugation to measure the stability of conductive paste c; then take an appropriate amount of conductive paste c for particle size and dispersion test, contact angle test, solid content and shear rate - Viscosity Change and Shear - Modulus Change Tests.

[0036] According to the test results, comparing the scratches left by the conductive pastes in Examples 1 to 3 on the same scraper fineness meter, the reading of the conductive paste b is the smallest (20 μm), followed by the reading of the conductive paste c (29 μm ), the reading of the conductive paste a is the largest (33 μm), in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com