Redox flow battery system

A technology of liquid flow batteries and battery stacks, which is applied in the direction of fuel cells, fuel cell additives, fuel cell control, etc., and can solve problems such as inability to completely avoid electrolyte mixing, inconvenient maintenance, and complex device structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

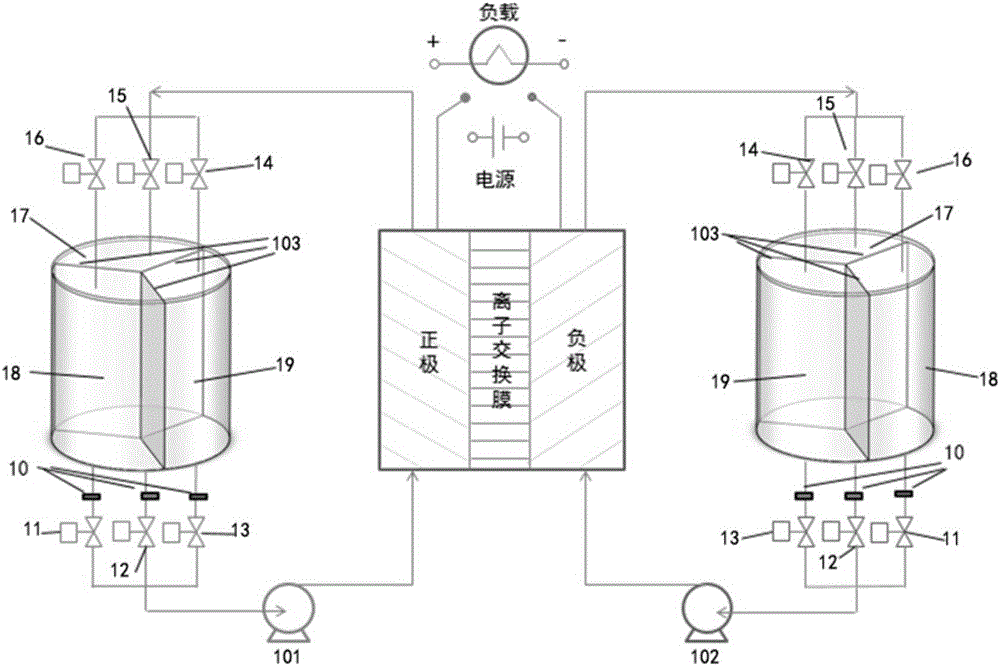

Embodiment 1

[0085] A flow battery system such as figure 1 As shown, the storage tank separator 103 is used to divide the positive electrode electrolyte storage tank into three cavities, which are respectively No. 1 cavity 17, No. 2 cavity 18, and No. 3 cavity 19. No. 1 and No. 3 cavity liquid inlet pipelines and cavity liquid outlet pipelines, and the No. 1 cavity liquid inlet valve (electric ball valve 15) and the No. Liquid valve (electric ball valve 16), No. 3 cavity liquid inlet valve (electric ball valve 14), No. 1 cavity liquid outlet valve (electric ball valve liquid valve (electric ball valve 11), No. 3 cavity liquid outlet valve (electric ball valve 13); end, as a branch of the main liquid outlet pipeline of the liquid flow circulation pipeline, the main liquid outlet pipeline is connected to the electrolyte outlet of the positive electrode; and the liquid outlet pipelines of No. 1, No. 2 and No. 3 cavities are connected in parallel It is arranged at the liquid outlet end of th...

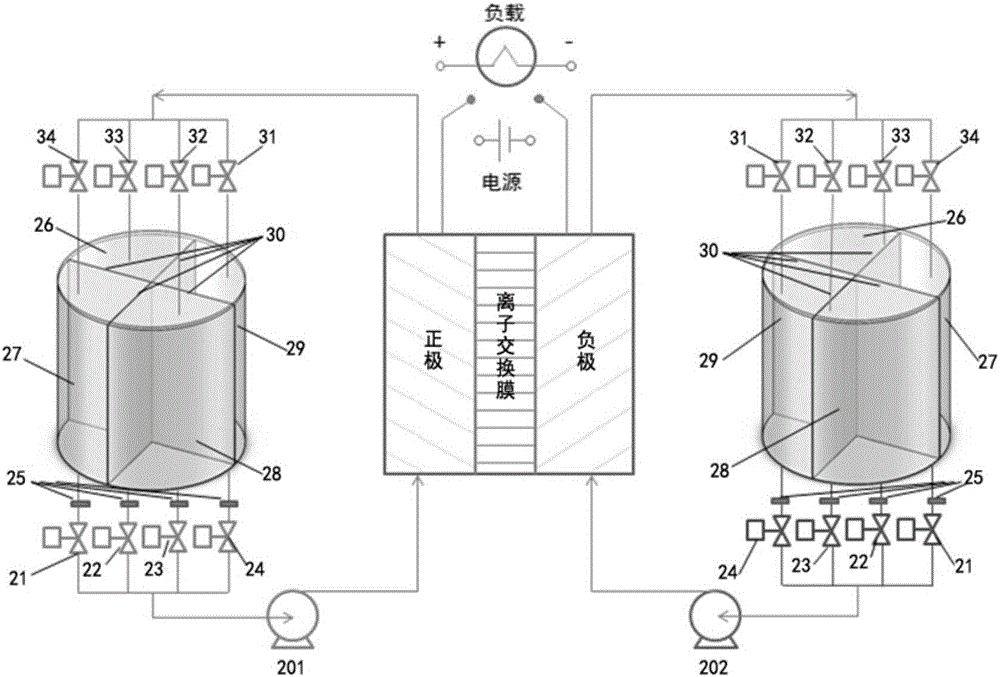

Embodiment 2

[0095] A flow battery system such as figure 2 As shown, the storage tank separator 30 is used to divide the positive electrode electrolyte storage tank etc. into four cavities, respectively No. 1 cavity 26, No. 2 cavity 27, No. 3 cavity 28, and No. 4 cavity 29. No. 1, No. 2, No. 3, and No. 4 cavity liquid inlet pipelines and cavity liquid outlet pipelines are connected, and the No. 1 cavity liquid inlet valve (electric Butterfly valve 33), No. 2 chamber liquid inlet valve (electric butterfly valve 34), No. 3 chamber liquid inlet valve (electric butterfly valve 32), No. 4 chamber liquid inlet valve (electric butterfly valve 31), liquid outlet in their respective chambers The pipeline is equipped with the liquid outlet valve of No. 1 chamber (electric butterfly valve 22), the liquid outlet valve of No. 2 chamber (electric butterfly valve 21), the liquid outlet valve of No. 3 chamber (electric butterfly valve 23), and the liquid outlet valve of No. 4 chamber (electric butterfly v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com