Method and device for removing heavy metal ions in wastewater by virtue of photoelectrocatalysis

A heavy metal ion, photoelectric catalysis technology, applied in chemical instruments and methods, light water/sewage treatment, water/sewage treatment, etc., can solve the problems of high energy consumption, high cost, low voltage efficiency, etc., achieve low energy consumption, Simple method and high voltage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

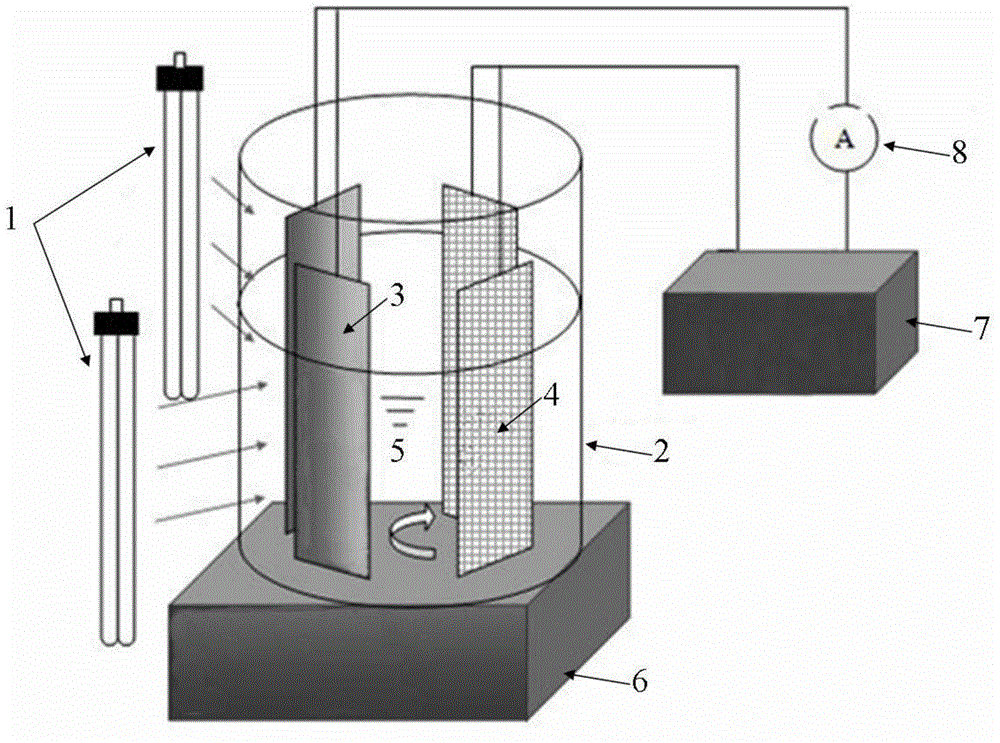

[0033] In this embodiment, a titanium mesh is used as a photoanode, and a Pt electrode is used as a counter electrode to remove Cr(VI) ions in wastewater.

[0034] The preparation method of the photoanode: cut the titanium mesh purchased in the market into a certain size rectangle, and then ultrasonically clean it in acetone, ethanol, and deionized water, and then wash it in HF:HNO 3 :H 2 Polish in O=1:3:16 mixed solution for 30s, rinse with deionized water, and dry.

[0035] The preparation method of the counter electrode: After polishing the Pt electrode purchased in the market with sandpaper, immerse it in dilute nitric acid for a period of time, rinse it with deionized water after taking it out, and dry it in the air.

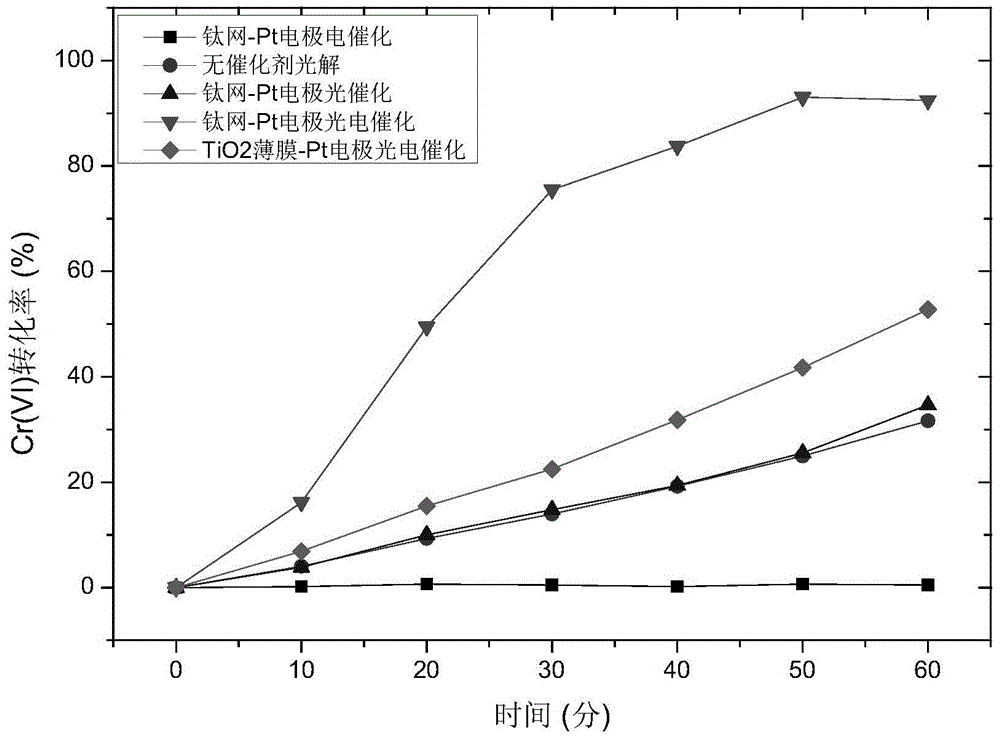

[0036] In this example, a 76mm×26mm titanium mesh (thickness 0.2mm, purity 99.9%, wire diameter 0.12mm, mesh number 60 mesh) was used as the photoanode, the Pt electrode was used as the counter electrode, and the cathode-to-anode area ratio was 1:50. The ...

Embodiment 2

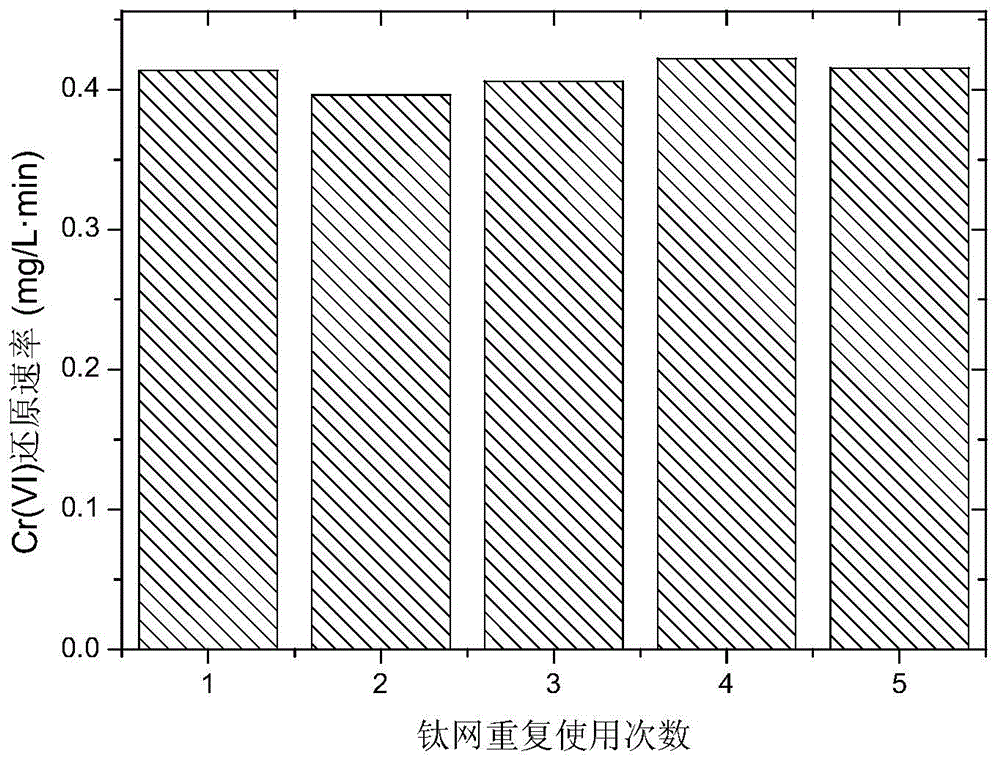

[0039] Using the method and device of the present invention, the initial concentration of Cr(VI) in the reaction system is 0.34mmol / L, reaction conditions: pH3.4, citric acid 0.5mmol / L, Na 2 SO 4 0.5mol / L, voltage 1.5V. Reproducible experiments for photocatalytic reduction of Cr(VI) using Ti mesh photoanode and Pt electrode photocathode. image 3 It means that the same clean titanium mesh was used to repeat 5 experiments, and the relative standard deviation of the 5 experiments was 2.4%, and the repeatability was very good, indicating that the titanium mesh can be used repeatedly for a long time.

Embodiment 3

[0041] Using the method and device of the present invention, the initial concentration of Cr(VI) in the reaction system is 0.34mmol / L, reaction conditions: pH3.4, citric acid 0.5mmol / L, Na 2 SO 4 0.5mol / L, voltage 1.5V. Using the Ti mesh photoanode and Ti mesh photocathode to carry out the photocatalytic reduction experiment of Cr(VI), 76% of Cr(VI) with an initial concentration of 0.34mmol / L can be degraded within 60 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com