Porous body and polishing pad

A porous body and polishing pad technology, which is applied in the field of porous bodies, can solve the problems of decreased grinding life, decreased grinding rate, and easy blockage of micropore chambers, and achieves the effect of not being easy to close pores and excellent abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

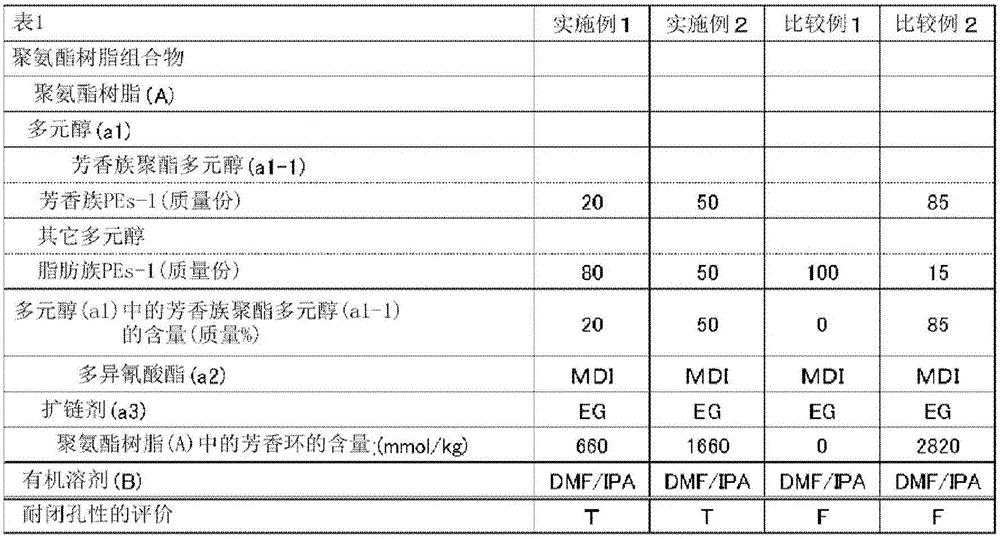

[0086] Aromatic polyester polyol (made by reacting ethylene glycol with phthalic acid, number average molecular weight 2,000, abbreviated as "aromatic PEs-1" ) 20 parts by mass, aliphatic polyester polyol (formed by reacting ethylene glycol with adipic acid, number average molecular weight 2,000, hereinafter abbreviated as "aliphatic PEs-1") 80 parts by mass, ethylene glycol (hereinafter abbreviated 8 parts by mass of "EG"), 357 parts by mass of N,N-dimethylformamide (hereinafter abbreviated as "DMF"), and 45 parts by mass of 4,4'-diphenylmethane diisocyanate (hereinafter abbreviated as "MDI") Parts by mass were reacted at 60° C. for 6 hours with stirring, then 1 part by mass of isopropyl alcohol (hereinafter abbreviated as “IPA”) was added, and stirred at 60° C. for 1 hour to obtain a polyurethane resin composition. The above polyurethane resin composition had a solid content of 30% by mass, a viscosity of 800 dPa·s, a weight average molecular weight of the polyurethane resin...

Embodiment 2

[0089] The usage-amount of above-mentioned aromatic PEs-1 is changed from 20 mass parts to 50 mass parts, the usage-amount of above-mentioned aliphatic PEs-1 is changed from 80 mass parts to 50 mass parts, obtains in the same way as Example 1 except that A polyurethane resin composition and a porous body. The above polyurethane resin composition had a solid content of 30% by mass, a viscosity of 950 dPa·s, a weight average molecular weight of the polyurethane resin of 91,000, and an aromatic ring content of 1,660 mmol / kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com