Emulsifier composition and use thereof

A technology of composition and emulsifier, which is applied in the production/processing of edible oil/fat, edible oil/fat containing fatty acid ester, etc., can solve the problem that there is no research on the content of phospholipid monomers, and there is no mention of the fineness of phospholipid oil composition , the impact of smearing performance and other issues, to achieve the effect of superior smearing performance, excellent emulsification performance, and fine particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

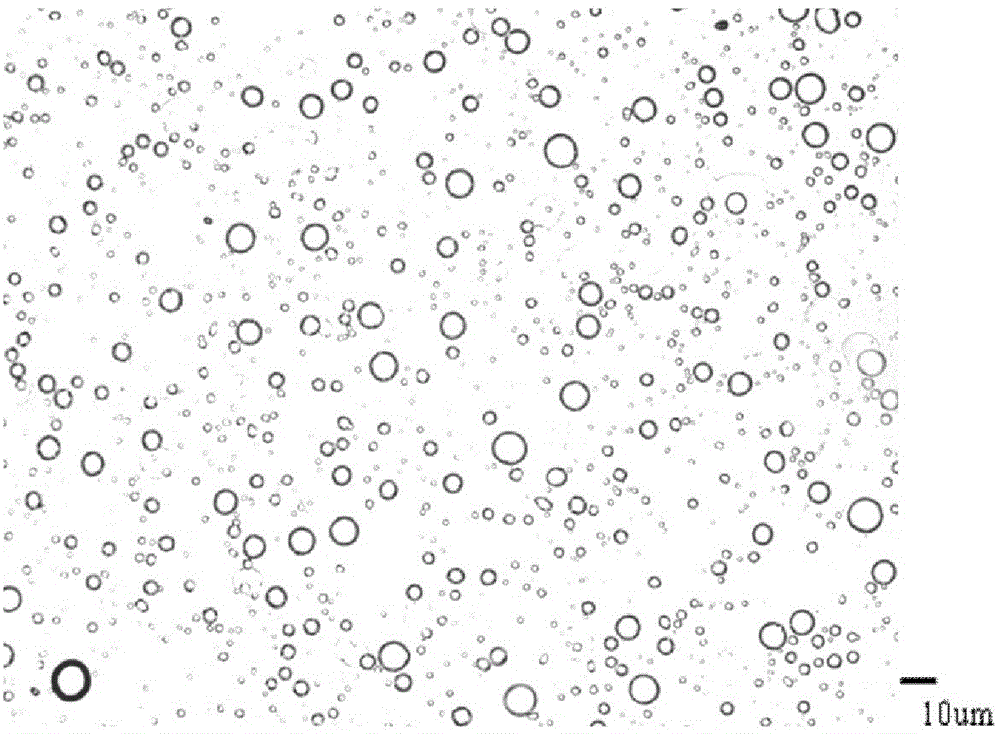

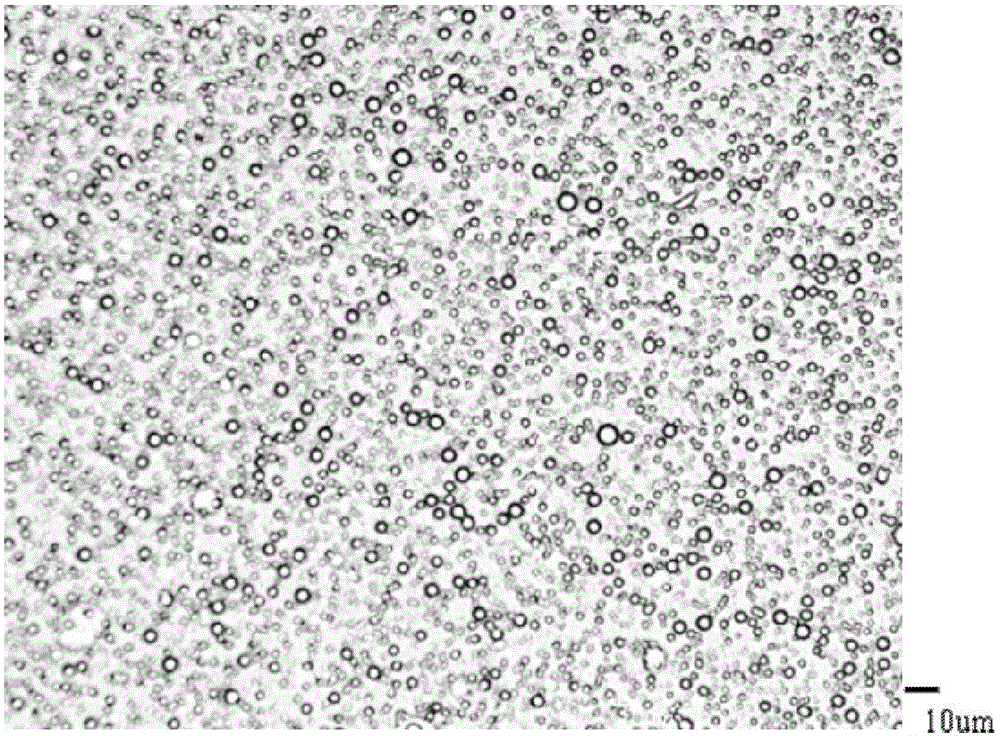

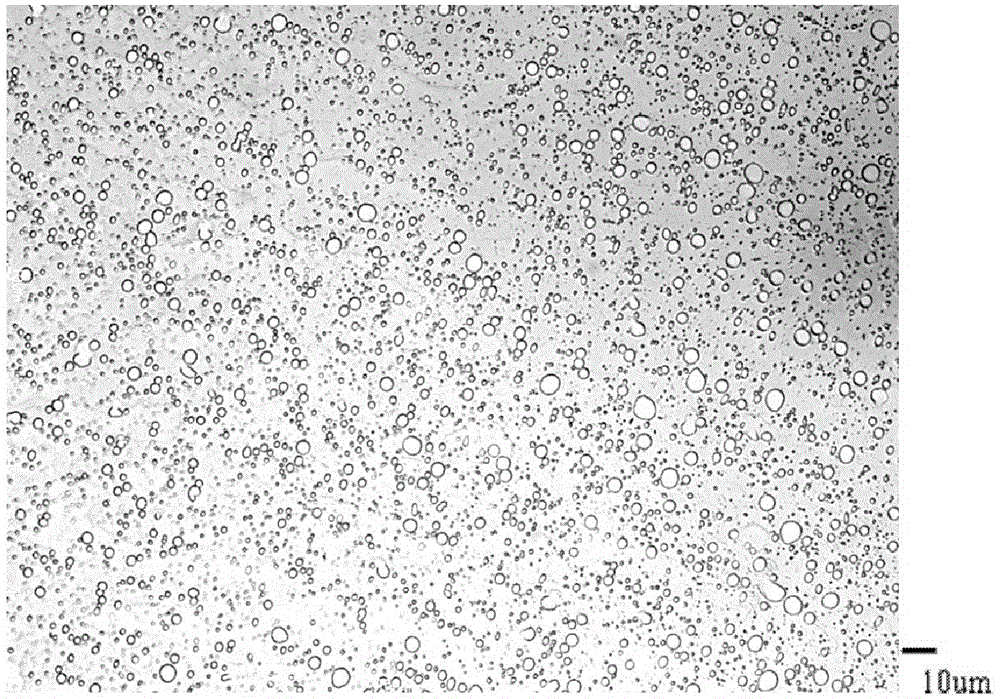

Image

Examples

preparation example Construction

[0112] The preparation method of oil-water composition

[0113] The preparation method of the oil-water composition of the present invention comprises (1) providing oil, water-soluble components and phospholipids; (2) emulsifying the above-mentioned components.

[0114] In a preferred embodiment of the present invention, the oil phase components are obtained by dissolving the oil, the phospholipid, and an optional emulsifier. Dissolution can be performed under heating, and the heating temperature is, for example, 50-80°C, preferably 65-75°C. The temperature of the obtained oil phase component is preferably lowered to 40 to 70°C, preferably 55 to 60°C.

[0115] The fats, phospholipids, and emulsifiers are, for example, the fats, phospholipids, and emulsifiers described in the present invention.

[0116] The amount of the oil added is not particularly limited, and without affecting the purpose of the present invention, based on the total amount of raw materials, 50 to 99% by w...

reference example 1

[0164] Reference example 1 Preparation of phospholipid

[0165] Phospholipids A to D are obtained by mixing powdered phospholipids and graded phospholipids. The powdered phospholipids are commercially available products, and the graded phospholipids are prepared according to the method of "Research on the Preparation of High-purity Phosphatidylcholine from Soybean Lecithin, Henan University of Technology, 2010, Wang Chengtao's master's thesis" . Phospholipid E (Cargill TOPCOTHINDBLECITHIN, USA) and Phospholipid F (Edible Soy Lecithin (YelkinSS) from Qinhuangdao Jinhai Food Industry Co., Ltd.) are commercially available concentrated soybean lecithin.

[0166] Table 1

[0167]

Embodiment 1~7

[0168] Implementation 1-7 Preparation of oil composition

[0169] Weigh the emulsifier sequentially according to Table 2 b , phospholipids, and oils, heated to 65-75°C to dissolve, to obtain oil phase components; dissolve each water-soluble component (salt, potassium sorbate) in water, and heated to 55-60°C, to obtain water-phase components. Cool the oil phase to 55-60°C, slowly add it dropwise to the obtained water phase components, emulsify for 20-30 minutes, and knead rapidly at -10°C, control the final temperature of the system at 3-5°C, and finally place the obtained composition at room temperature to grow crystals After 1-2 hours, after the crystal growth is completed, stir if necessary to maintain the appropriate fluidity of the composition, put it into a suitable bottle for refrigeration or store at room temperature, and obtain the oil composition of Examples 1-7.

[0170] Table 2

[0171]

Example 1 Example 2 Example 3 Example 4 Example 5 Exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com