Zinc oxide/reduced graphene oxide aerogel and preparation method of zinc oxide/reduced graphene oxide aerogel

A graphene aerogel, zinc oxide technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of unfavorable large-area preparation and no graphene It can be combined with zinc oxide and high temperature, so as to achieve the effect of low cost, strong practicability and high utilization rate of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Take 30mg graphene oxide and soak it in 60ml ethylene glycol for 1h, and in an ultrasonic device with a power of 100W, sonicate for 4h at room temperature to obtain a uniform graphene oxide ethylene glycol dispersion;

[0031] (2) Add 0.544g of zinc acetate, 0.2g of sodium citrate, and 1.2g of sodium acetate to the above dispersion in sequence, and stir evenly with magnetic force;

[0032] (3) Transfer the above mixed solution to the reaction kettle, take it out after reacting at 160° C. for 10 h, and wash repeatedly with deionized water and absolute ethanol several times;

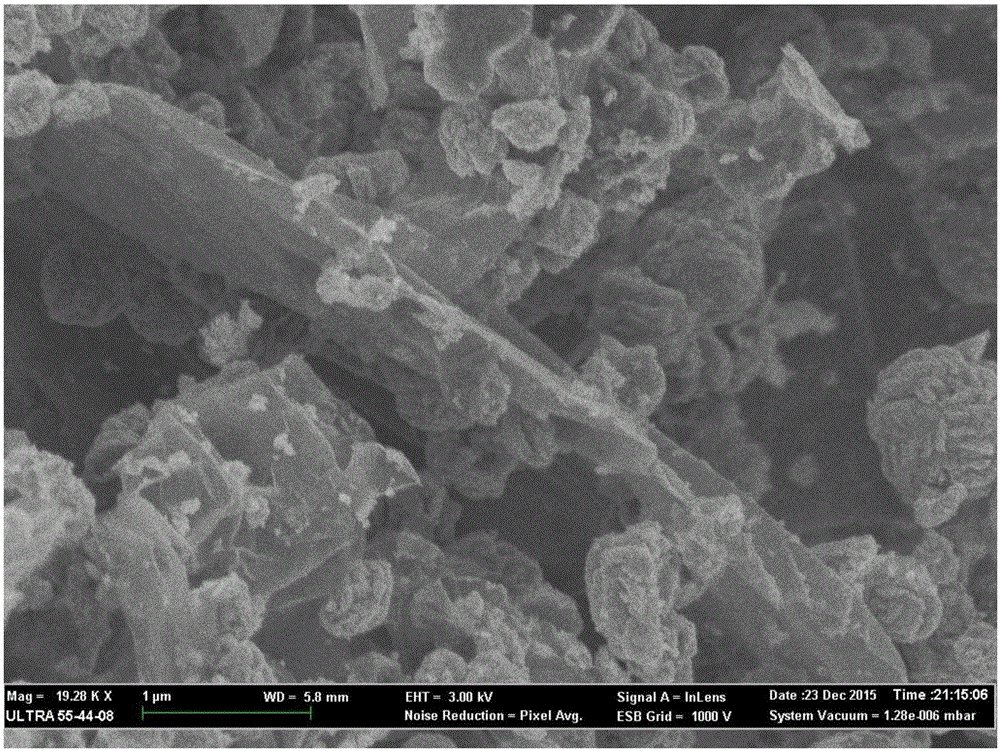

[0033] (4) Zinc oxide / reduced graphene oxide airgel can be obtained by placing it in a freeze-drying box for 12 hours. Its surface morphology is as figure 1 As shown, we can see the obvious mesoporous structure formed by graphene folds, because the prepared graphene and zinc oxide composite structure is interconnected and stacked in three-dimensional space to form a porous structure, even this ...

Embodiment 2

[0035] (1) Take 60mg of graphene oxide and soak it in 60ml of ethylene glycol for 1h, and ultrasonically 4h at room temperature in an ultrasonic device with a power of 100W to obtain a uniform graphene oxide glycol dispersion;

[0036] (2) Add 0.544g of zinc chloride, 0.2g of sodium citrate, and 1.2g of sodium acetate to the above-mentioned dispersion in sequence, and stir evenly with magnetic force;

[0037] (3) Transfer the above mixed solution to the reaction kettle, take it out after reacting at 160° C. for 10 h, and wash repeatedly with deionized water and absolute ethanol several times;

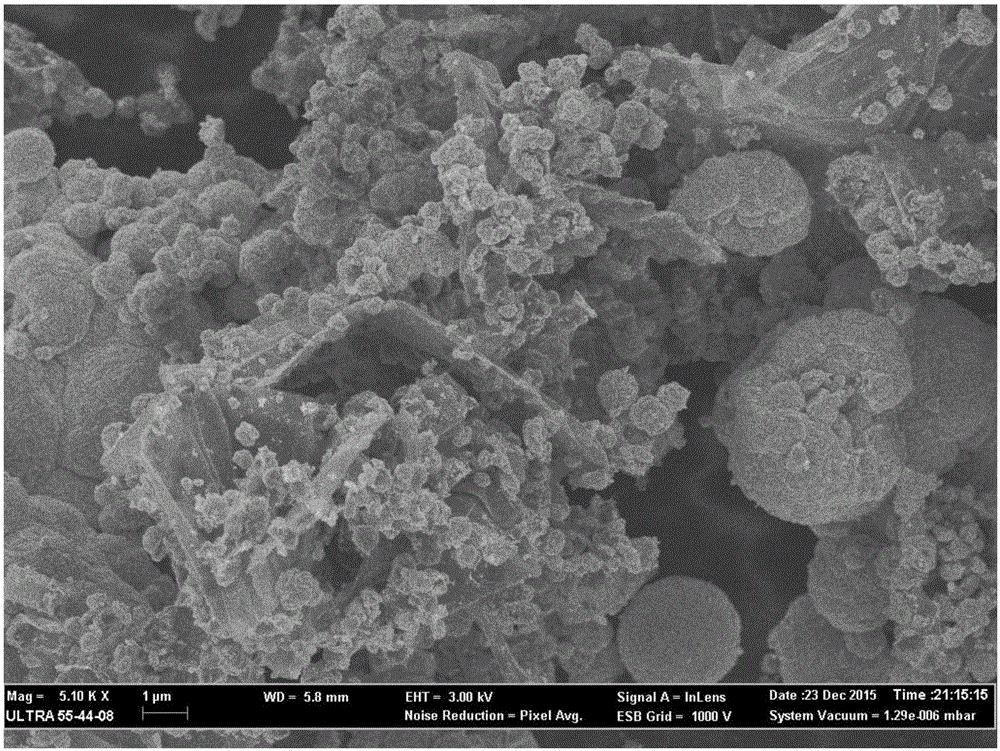

[0038] (4) Zinc oxide / reduced graphene oxide airgel can be obtained by placing it in a freeze-drying box for 12 hours. Its surface morphology is as figure 2Shown, in this embodiment, reduced the concentration of graphene oxide, while observing the similar mesoporous structure in embodiment 1, found that the number of spherical zinc oxide nanoparticles is more, also is interspersed in ...

Embodiment 3

[0040] (1) Take 60mg of graphene oxide and soak it in 60ml of ethylene glycol for 1h, and ultrasonically 4h at room temperature in an ultrasonic device with a power of 100W to obtain a uniform graphene oxide glycol dispersion;

[0041] (2) Add 1.088g of zinc acetate, 0.2g of sodium citrate, and 1.2g of sodium acetate to the above dispersion in sequence, and stir evenly with magnetic force;

[0042] (3) Transfer the above mixed solution to the reaction kettle, take it out after reacting at 160° C. for 10 h, and wash repeatedly with deionized water and absolute ethanol several times;

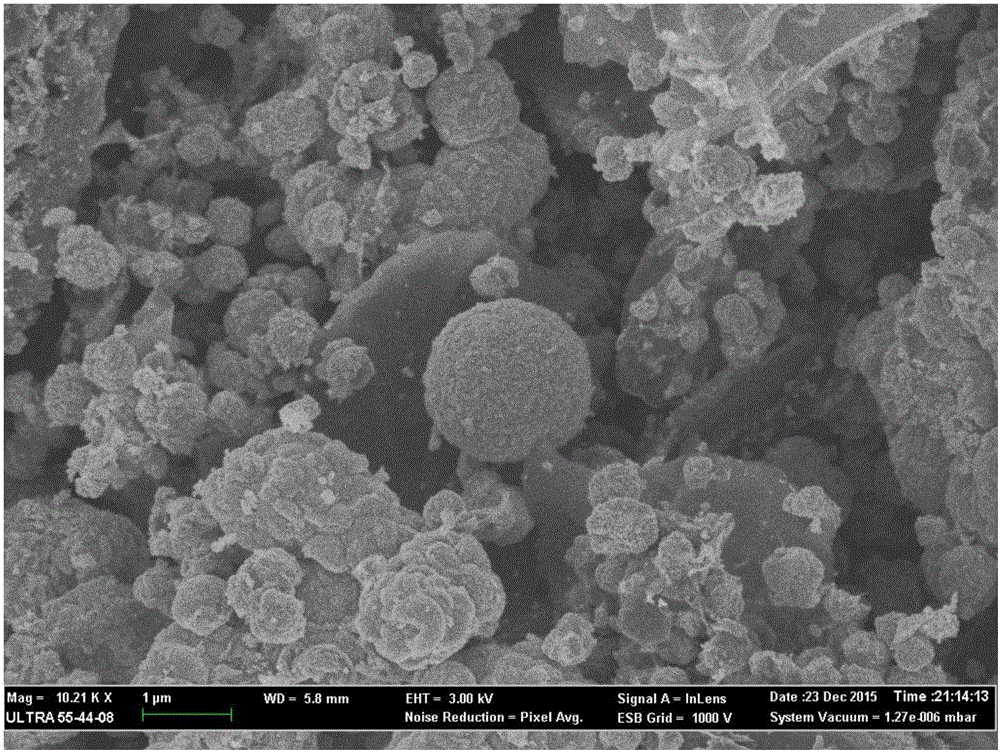

[0043] (4) Zinc oxide / reduced graphene oxide airgel can be obtained by placing it in a freeze-drying box for 12 hours. Its surface morphology is as image 3 As shown, in fact, it is very similar to Example 2, and the mesoporous structure is also obvious, probably because of the increase of Zn 2+ The amount of the final ZnO nanosphere structure becomes more.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com