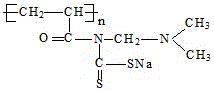

Polyacrylamide heavy metal flocculating agent and method for preparing same

A polyacrylamide-based and polyacrylamide technology is applied in the field of polyacrylamide-based heavy metal flocculants and their preparation, which can solve the problems of inability to reach the standard stably, poor sedimentation, and large amount of sludge in acidic heavy metal wastewater, and achieve good The effect of application prospect, fast settling speed and simple and easy governance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

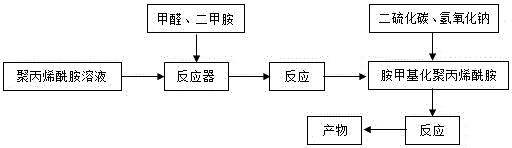

Method used

Image

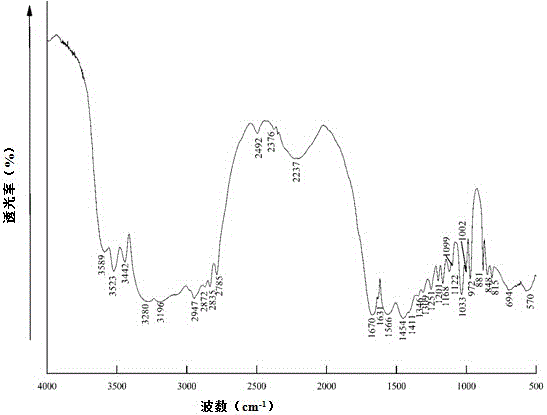

Examples

Embodiment 1

[0030] (1) Weigh 1.0g of polyacrylamide with a relative molecular mass of 3 million, add it to a reactor with magnetic stirring, add 100g of distilled water, stir and dissolve, and make a polyacrylamide solution with a mass percentage concentration of 1.0%; Then add 1.5mL of commercially available formaldehyde solution into the reactor, adjust the reaction temperature to 63°C, stir and react for 90min under the condition of stirring speed 200r / min; then add 7.5mL of commercially available dimethylamine solution into the reactor, The reaction temperature was adjusted to 63°C, and the stirring reaction was continued for 3 hours under the condition of a stirring speed of 200r / min, and the intermediate product amine-methylated polyacrylamide was obtained after cooling;

[0031] (2) Add 1.5mL of sodium hydroxide with a concentration of 40% by mass and 1.5mL of commercially available carbon disulfide into the reactor in step (1), adjust the temperature to 25°C, and stir at a stirring...

Embodiment 2

[0033] (1) Weigh 3.0g of polyacrylamide with a relative molecular mass of 3 million, add it to a reactor with magnetic stirring, add 100g of distilled water, stir and dissolve, and make a polyacrylamide solution with a mass percentage concentration of 3.0%; Then add 4.5 mL of commercially available formaldehyde solution into the reactor, adjust the reaction temperature to 57°C, and stir for 70 minutes at a stirring speed of 200 r / min; then add 22.5 mL of commercially available dimethylamine solution into the reactor, Adjust the reaction temperature to 57°C, and continue to stir the reaction for 2.8 hours under the condition of stirring speed of 200r / min, and obtain the intermediate product amine-methylated polyacrylamide after cooling;

[0034] (2) Add 5.5mL of sodium hydroxide with a concentration of 40% by mass and 5.0mL of commercially available carbon disulfide into the reactor in step (1), adjust the temperature to 20°C, and stir at a stirring speed of 200r / min After reac...

Embodiment 3

[0036] (1) Weigh 4.0g of polyacrylamide with a relative molecular mass of 3 million, add it to a reactor with magnetic stirring, add 100g of distilled water, stir and dissolve, and make a polyacrylamide solution with a mass percentage concentration of 4.0%; Then add 6.0 mL of commercially available formaldehyde solution into the reactor, adjust the reaction temperature to 60°C, and stir and react for 50 min at a stirring speed of 200 r / min; then add 30.0 mL of commercially available dimethylamine solution into the reactor, The reaction temperature was 60°C and the stirring speed was 200r / min, and the stirring reaction was continued for 2.5h, and the intermediate product amine-methylated polyacrylamide was obtained after cooling;

[0037](2) Add 17.0mL of sodium hydroxide with a concentration of 40% by mass and 10.0mL of commercially available carbon disulfide into the reactor in step (1), adjust the temperature to 35°C, and stir at a stirring speed of 200r / min After reacting f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com