A kind of silicon-ceramic sheet with adjustable water absorption and its preparation method

A technology of water absorption and silicon porcelain, which is applied in the field of building materials, can solve the problems of increasing the owner's one-time investment cost, increasing construction cost and construction cost, and increasing the strength requirements of the supporting structure, so as to reduce construction cost and construction cost, and its own weight Effect of reduction, area expansion of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

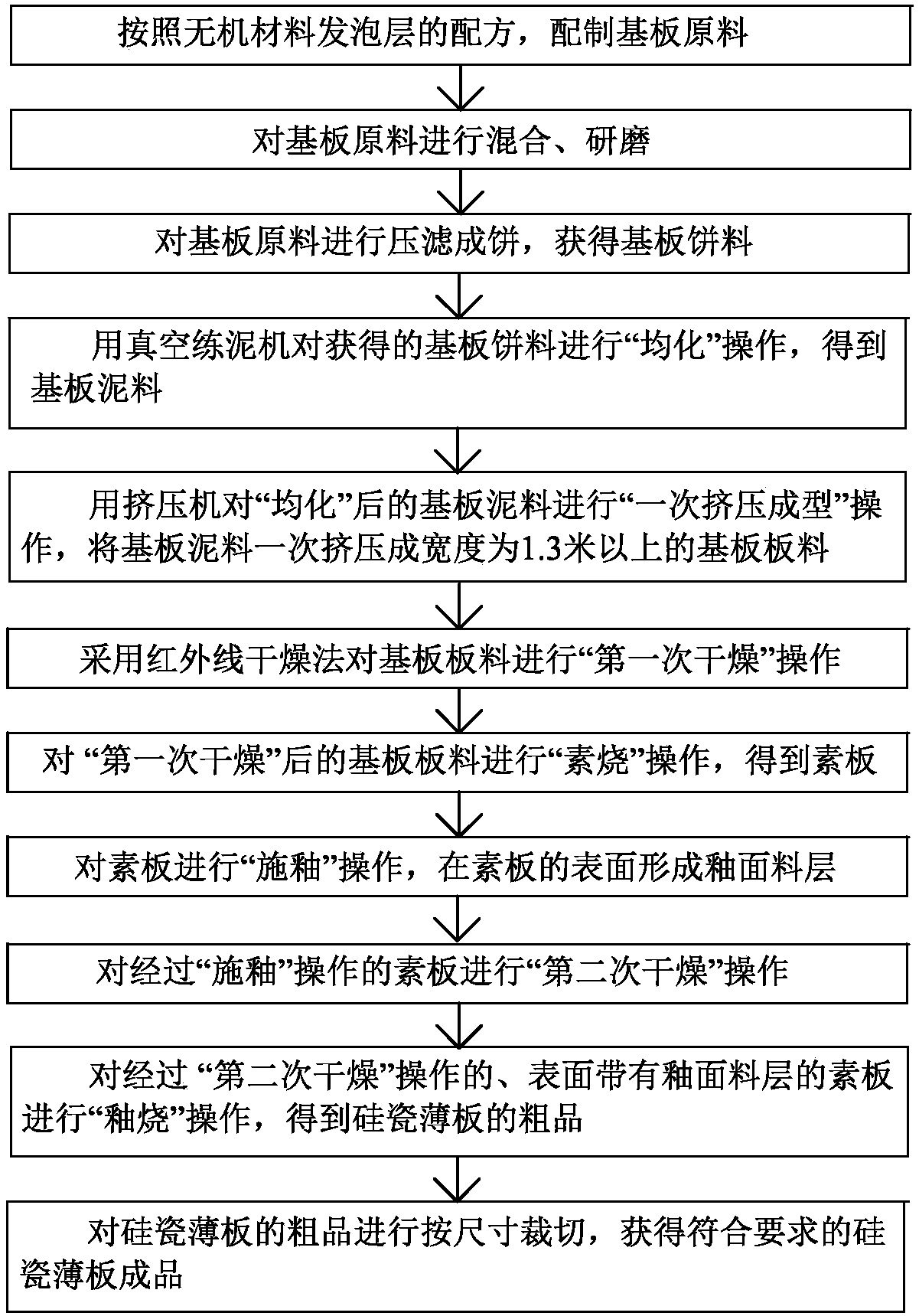

[0066] figure 2 Among them, the technical solution of the present invention also provides a kind of preparation method of above-mentioned silicon-ceramic sheet, and its inventive point is that described preparation method comprises the following steps at least:

[0067] A. Prepare substrate raw materials according to the formula of inorganic material foaming layer;

[0068] B. Mix and grind the substrate raw materials;

[0069] C. Press-filter the raw material of the substrate into a cake to obtain the substrate cake;

[0070] D. Use a vacuum mud mixer to "homogenize" the obtained substrate cake to obtain the substrate mud;

[0071] E. Use an extruder to perform a "one-time extrusion molding" operation on the "homogenized" substrate mud, and extrude the substrate mud into a substrate sheet with a width of more than 1.3 meters;

[0072] F. Use the infrared drying method to perform the "first drying" operation on the substrate sheet;

[0073] G. Perform "biscuit burning" op...

Embodiment 1

[0096] A. Prepare substrate raw materials according to the formula of inorganic material foaming layer:

[0097] The raw material formula (by weight, the same below) of its inorganic material foaming layer is: feldspar: 10 parts; clay: 15 parts; quartz: 5 parts; kaolin: 10 parts; wollastonite: 5 parts; limestone: 8 parts parts; auxiliary tackifier: 1 part.

[0098] The auxiliary thickening agent is industrial grade seaweed powder.

[0099] B, mixing and grinding the raw materials of the substrate (inorganic material foam layer);

[0100] C. Press-filter the raw material of the substrate into a cake to obtain the substrate cake;

[0101] D. Use a vacuum mud mixer to "homogenize" the obtained substrate cake to obtain the substrate mud;

[0102] E. Use an extruder to perform a "one-time extrusion molding" operation on the "homogenized" substrate mud, and extrude the substrate mud into a substrate sheet with a width of more than 1.3 meters;

Embodiment 2

[0121] In the raw material formula of the inorganic material foaming layer, feldspar: 30 parts; clay: 40 parts; quartz: 10 parts; kaolin: 25 parts; wollastonite: 15 parts; limestone: 15 parts; auxiliary tackifier: 5 parts .

[0122] The auxiliary tackifier is xanthan gum.

[0123] The mixing and grinding time of the substrate raw materials is 12 hours, and the moisture content of the substrate raw materials after mixing and grinding is 35%;

[0124] The temperature of the "first drying" operation is 250 degrees and the time is 100 minutes;

[0125] The temperature of the "second drying" operation is 200 degrees and the time is 60 minutes;

[0126] The temperature of the "biscuit burning" operation is 1150 degrees, and the time is 80 minutes;

[0127] The temperature of the "glaze burning" operation is 1230 degrees, and the time is 120 minutes;

[0128] After the rough product of the silicon ceramic thin plate is obtained, the surface polishing operation is performed on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com