Process method for preparing organic liquid fertilizer by using leather production lime plte wastes

The technology of an organic liquid and a process method is applied in the field of preparing organic liquid fertilizer and using tanning gray leather waste to prepare organic liquid fertilizer, which can solve the problems of weakening the significance and effect of green utilization of leather waste, and achieve the improvement of treatment and utilization capacity and the improvement of replenishment. Technical blank, avoid the effect of low pH value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

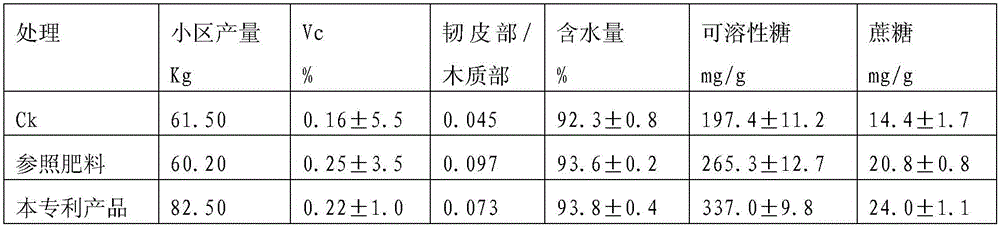

Image

Examples

Embodiment 1

[0018] A process for preparing organic liquid fertilizer from tanning gray hide waste, comprising the following technical steps:

[0019] Step 1: Clean the leather waste and cut it into smaller than 1cm 2 Add water with the same weight ratio as the leather waste, and then add 0.1% leather waste weight of biological enzymes, then heat to 30°C and keep the enzymolysis time controlled for more than 60 hours until the enzymolysis is sufficient, and the enzymolysis solution is obtained for use ; What described biological enzyme adopts is neutral protease.

[0020] Step 2: adding 0.5‰ of the enzymatic hydrolyzate weight microbial agent to obtain the fermented liquid for later use; the microbial agent mainly uses lactic acid bacteria; the lactic acid bacteria mainly play a role in keeping the proteolytic solution fresh and preventing corruption and odor;

[0021] Step 3: Add boric acid, zinc sulfate, ferrous sulfate, magnesium sulfate and calcium nitrate in sequence to the fermented...

Embodiment 2

[0024] A process for preparing organic liquid fertilizer from tanning gray hide waste, comprising the following technical steps:

[0025] Step 1: Clean the leather waste, add water with the same weight ratio as the leather waste, and then add 1% leather waste weight of biological enzymes, then heat to 60°C and keep the enzymatic hydrolysis time controlled for more than 60 hours until the enzymatic hydrolysis is sufficient. Obtaining the enzymatic hydrolysis solution for subsequent use; the biological enzyme used is neutral protease;

[0026] Step 2: adding 8‰ of the enzymatic hydrolyzate weight of microbial inoculum to obtain the fermented liquid for later use; the microbial inoculum mainly adopts lactic acid bacteria;

[0027] Step 3: Add boric acid, zinc sulfate, ferrous sulfate, magnesium sulfate and calcium nitrate in sequence to the fermented liquid obtained in Step 2, and mix well to obtain an organic liquid fertilizer. Based on the weight of the fermented liquid, the a...

Embodiment 3

[0029] A process for preparing organic liquid fertilizer from tanning gray hide waste, comprising the following technical steps:

[0030] Step 1: Clean the leather waste, add water with the same weight ratio as the leather waste, and then add 0.5% leather waste weight of biological enzymes, then heat to 50°C and keep the enzymatic hydrolysis time controlled for more than 60 hours until the enzymatic hydrolysis is sufficient. Obtaining the enzymatic hydrolysis solution for subsequent use; the biological enzyme used is neutral protease;

[0031] Step 2: adding 3‰ of the enzymatic hydrolyzate weight of microbial inoculum to obtain the fermented liquid for later use; the microbial inoculum mainly adopts lactic acid bacteria;

[0032] Step 3: Add boric acid, zinc sulfate, ferrous sulfate, magnesium sulfate and calcium nitrate in sequence to the fermented liquid obtained in Step 2, and mix well to obtain an organic liquid fertilizer. Based on the weight of the fermented liquid, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com