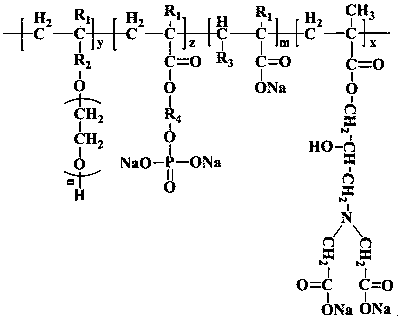

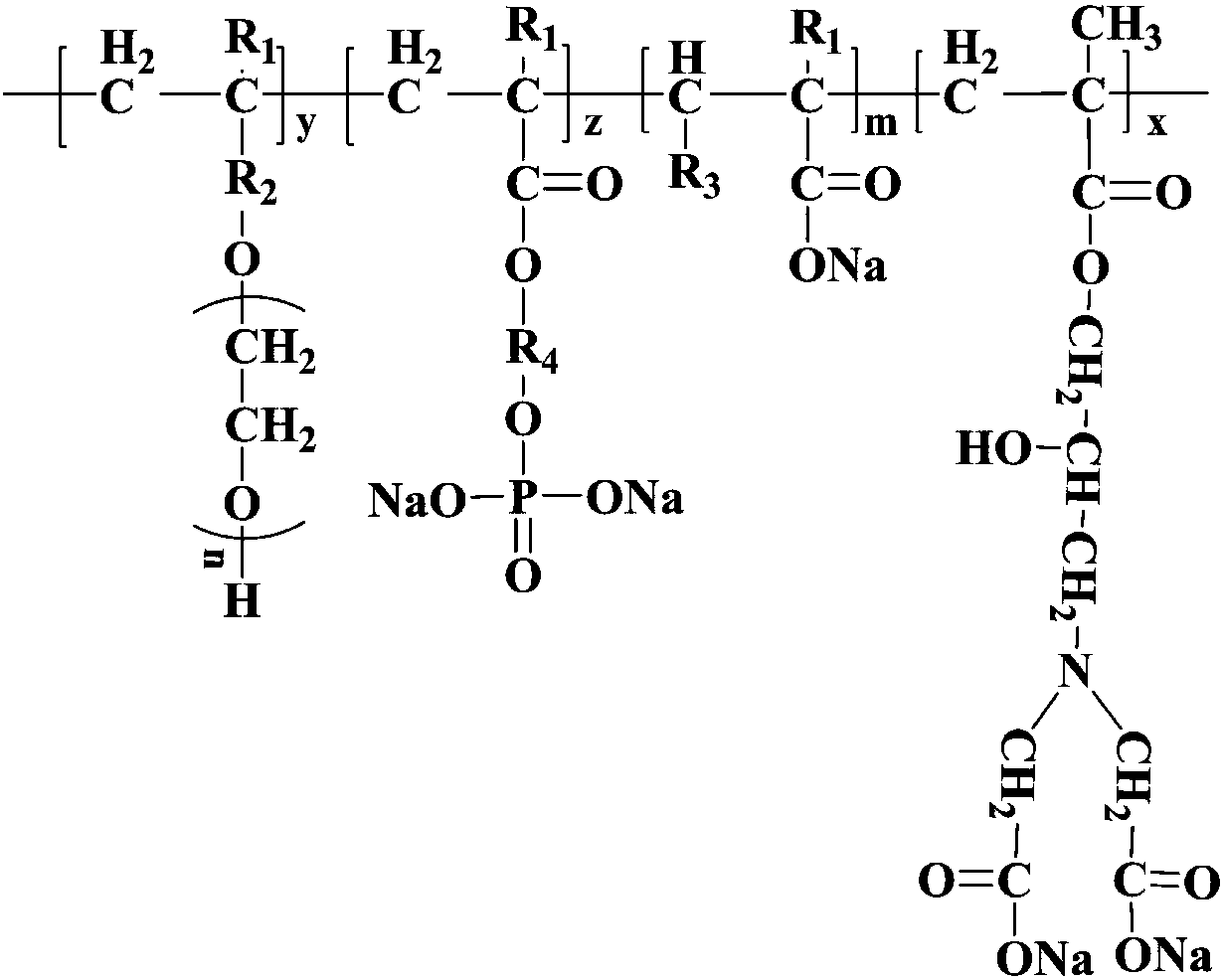

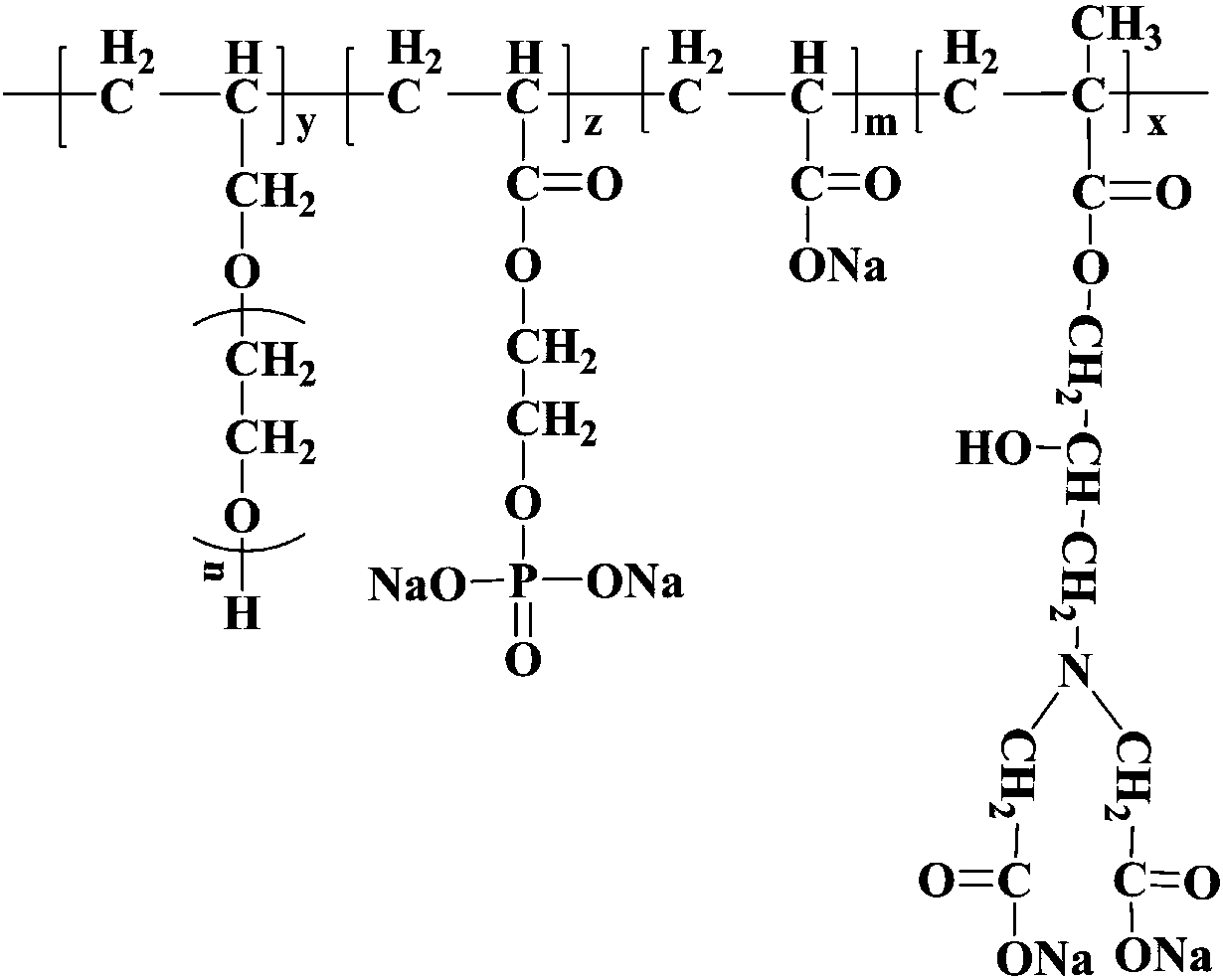

A kind of phosphate-containing high adaptability polycarboxylate water reducing agent and preparation method thereof

A phosphate ester and adaptable technology, applied in the field of building materials, can solve the problems of segregation bleeding, poor workability, poor adaptability, and insufficient slump-preserving performance, and achieve the goal of improving dispersion ability, strong adsorption capacity, and improving slump-preserving performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A preparation method of a highly adaptable polycarboxylate water reducer containing phosphate, comprising the following steps:

[0014] Add 125g of water and 160g of polyether macromonomer APEG to a 1000mL four-necked round-bottomed flask equipped with a thermometer, an electric stirrer, a constant temperature electric heating mantle, and a peristaltic pump. The molecular weight of the APEG used is 2000-24000. After dissolving evenly, directly add the mixed solution of 1.6g hydrogen peroxide and 7g water and stir for 10 minutes to fully dissolve it. A mixed aqueous solution consisting of 20 g of acrylic acid, 3 g of hydroxyethyl acrylate phosphate, 2 g of 2-methacrylic acid-3 (N, N-diacetamide)-2 hydroxypropyl ester, and 35 g of water was added dropwise within 3 hours. Mixed solution composed of 0.35g ascorbic acid, 0.86g mercaptopropionic acid, and 40g water, the temperature is kept between 58-61°C; after the dropwise addition, continue to react for 2 hours, then cool ...

Embodiment 2

[0017] A preparation method of a highly adaptable polycarboxylate water reducer containing phosphate, comprising the following steps:

[0018] Add 145g of water and 160g of polyether macromonomer HPEG into a 1000mL four-necked round-bottomed flask equipped with a thermometer, an electric stirrer, a constant temperature electric heating mantle, and a peristaltic pump. The molecular weight of the HPEG used is 2000-24000. After dissolving evenly, directly add the mixed solution of 1.8g hydrogen peroxide and 7g water and stir for 10 minutes to fully dissolve it. A mixed aqueous solution consisting of 22 g of acrylic acid, 2 g of hydroxyethyl acrylate phosphate, 2 g of 2-methacrylic acid-3 (N, N-diacetamide)-2 hydroxypropyl ester, and 35 g of water was added dropwise within 3 hours. A mixed solution composed of 0.25g of ascorbic acid, 0.95g of mercaptopropionic acid, and 40g of water is kept at a temperature between 58-61°C; after the dropwise addition, the reaction is continued fo...

Embodiment 3

[0021] A preparation method of a highly adaptable polycarboxylate water reducer containing phosphate, comprising the following steps:

[0022] Add 135g of water and 150g of polyether macromonomer TPEG to a 1000mL four-necked round-bottomed flask equipped with a thermometer, an electric stirrer, a constant temperature electric heating mantle, and a peristaltic pump. The molecular weight of the TPEG used is 2000-24000. After dissolving evenly, directly add the mixed solution of 1.5g hydrogen peroxide and 8g water and stir for 10 minutes to fully dissolve it. A mixed aqueous solution consisting of 18 g of acrylic acid, 4 g of hydroxyethyl acrylate phosphate, 3 g of 2-methacrylic acid-3 (N, N-diacetamide)-2 hydroxypropyl ester, and 35 g of water was added dropwise within 3 hours. Mixed solution composed of 0.32g ascorbic acid, 1.14g mercaptopropionic acid, and 40g water, keep the temperature between 58-61°C; continue to react for 2 hours after the dropwise addition, then cool down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com