A kind of nano anti-reflection coating liquid and its preparation method and application

A coating solution and nanotechnology, applied in the direction of coating, etc., can solve the problems of complex process, high cost, short service life, etc., and achieve the effects of simple preparation process, improved adhesion, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 has the alcohol system nano-coating liquid I of anti-reflection function

[0026]The formula of alcohol system nano-coating solution I with anti-reflection function is shown in the following table:

[0027]

[0028] Preparation:

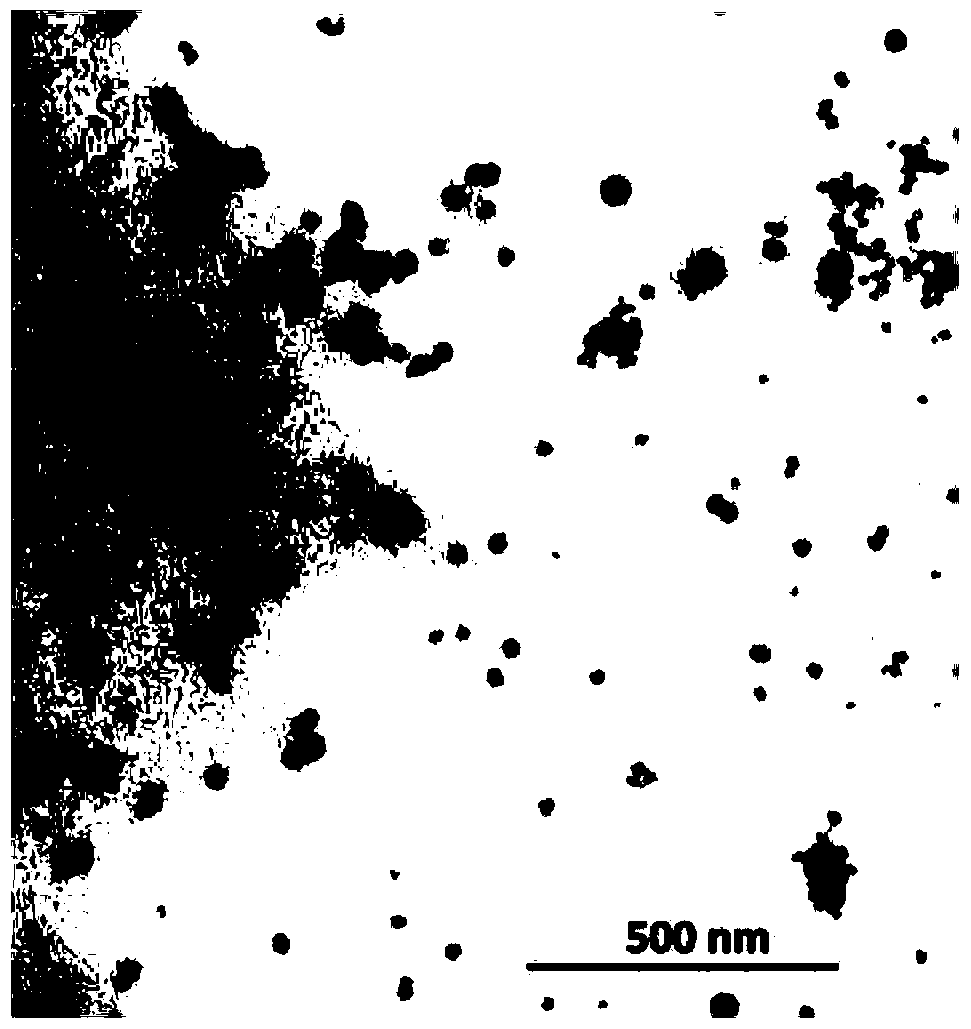

[0029] Dissolve the dispersant and the adhesion promoter in ethanol first, add the nano particles under the condition of stirring, mix evenly, and grind in a sand mill for 3 hours to obtain a stable dispersion liquid. The particle dispersion was characterized by transmission electron microscopy (TEM), such as figure 1 shown. The TEM observation results show that the nano-silica particles are uniformly dispersed in the solvent in the original state in the obtained dispersion, and there is no obvious agglomeration.

[0030] The porogen is dissolved in ethanol, and then the above-mentioned dispersion liquid and wetting agent are sequentially added under the stirring condition, and the alcohol system nano anti-reflection coating...

Embodiment 2

[0031] Embodiment 2 Nano anti-reflection coatings of different thicknesses

[0032] Preparation method: roll-coat the nanometer anti-reflection coating solution obtained in Example 1 on the glass surface, and control the roll-coating speed and bake at 600°C for 2 minutes to form films with thicknesses of 140 nm to 150 nm, 150nm-170nm and 180nm-200nm AR coatings.

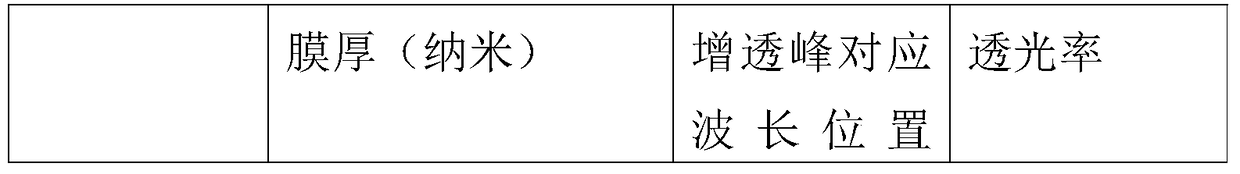

[0033] The anti-reflection performance of the obtained coating is characterized by a desktop transmittance spectrometer (Aubertai Air Floatation Desktop Spectral Transmittance Test System (Model Filmmeasure 2100). The test results obtained are shown in the following table:

[0034]

[0035]

[0036] The results show that the light transmittance of the obtained coated glass in the visible light region is higher than that of the uncoated glass, and the position corresponding to the anti-reflection peak is closely related to the film thickness.

[0037] When the film thickness is 140-150 nanometers, the light tra...

Embodiment 3

[0040] Example 3 Aqueous System Nano Anti-reflection Coating Solution and Anti-reflection Coating

[0041] The formula of the water-based nano anti-reflection coating solution with anti-reflection function is shown in the following table:

[0042]

[0043]

[0044] Preparation:

[0045] Dissolve the dispersant and the adhesion promoter in water first, add the nano particles under the condition of stirring, mix evenly, and grind in a sand mill for 8 hours to obtain a stable dispersion liquid.

[0046] The porogen is dissolved in water, and then the above-mentioned dispersion liquid and wetting agent are sequentially added under stirring condition, and the water-based nano-antireflection coating solution is obtained after stirring and mixing evenly.

[0047] The obtained nano anti-reflection coating solution is rolled onto the glass surface, and by controlling the speed of the roll coating, after baking at 700°C for 5 minutes, an anti-reflection coating with a film thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com