A Supercritical CO2 Microemulsion Formed from Anion-Non-Zwitterionic Surfactants

A surfactant and non-ionic surface technology, applied in the field of supercritical CO2 microemulsion, can solve the problems of affecting the charge distribution of the microemulsion interface layer, reducing the stability of the microemulsion, and the deterioration of hydrophilicity, so as to improve the interface activity, The effect of improving solubilizing ability and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

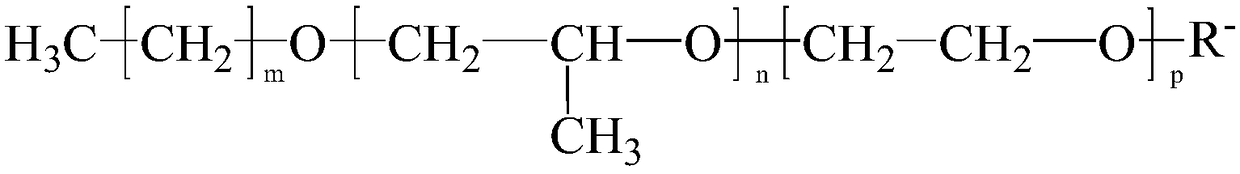

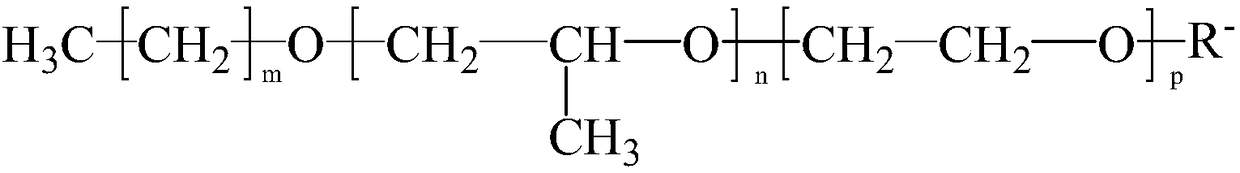

[0033] A supercritical CO formed from an anionic-nonzwitterionic surfactant 2 Microemulsion, in 100 parts by weight, consists of the following components: 1 part of water, 1.0×10 surfactant -2 Parts, 10 parts of co-solvent, CO 2 margin. The composition of the surfactant molecule in this composition is: m=7, n=1, p=10, R - For carbonate; co-solvent for ethanol. Supercritical CO 2 The cloud point pressure of the system at 50° C. was measured by a phase balance instrument to be 18.7 MPa, and the density at the cloud point pressure was 0.94 g / mL.

Embodiment 2

[0035] A supercritical CO formed from an anionic-nonzwitterionic surfactant 2 Microemulsion, in 100 parts by weight, consists of the following components: 1.0 part of water, 1.0×10 surfactant -2 Parts, 10 parts of co-solvent, CO 2 margin. The composition of surfactant molecules in this composition is: m=12, n=30, p=10, R - For sulfate; co-solvent for ethanol. Supercritical CO 2 The cloud point pressure of the system at 50° C. was measured by a phase balance instrument to be 13.1 MPa, and the density at the cloud point pressure was 0.82 g / mL.

Embodiment 3

[0037] A supercritical CO formed from an anionic-nonzwitterionic surfactant 2 Microemulsion, in 100 parts by weight, consists of the following components: 1.0 parts of water, 1.5×10 surfactants -3 Parts, 10 parts of co-solvent, CO 2 margin. The composition of the surfactant molecule in this composition is: m=8, n=11, p=13, R - For carbonate; co-solvent for ethanol. Supercritical CO 2 The cloud point pressure of the system at 50° C. was measured by a phase balance instrument to be 12.2 MPa, and the density at the cloud point pressure was 0.80 g / mL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com