A kind of alkali washing tower online cleaning agent and its preparation and use method

A technology for cleaning chemicals and alkaline washing towers, applied in detergent compositions, detergent compounding agents, chemical instruments and methods, etc. The effect of butter quantity and COD value, reducing accumulation and ensuring stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Add 30g of sodium fatty acid methyl sulfonate, 5g of dodecyldimethylbenzylammonium chloride, 8g of nonylphenol polyoxyethylene ether, 25g of carbohydrazide, and 32g of deionized water into the reactor. After stirring for 1 hour at room temperature Filter to obtain cleaning agent.

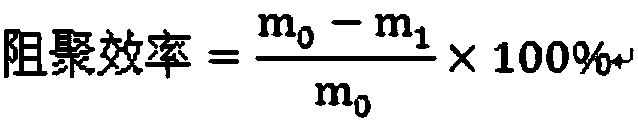

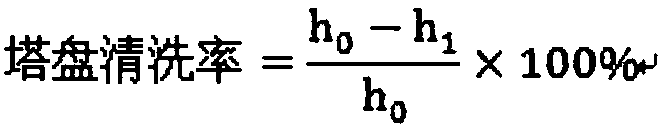

[0020] The above cleaning agent is applied to the ethylene caustic washing tower simulation device. A certain thickness of butter is attached to the caustic cleaning tower tray, and the water contains 500-1000ppm of butter. The online cleaning agent of the caustic cleaning tower is continuously injected into the circulating lye. It is 100ppm, and the ratio of the injection volume of the strong alkali section, the medium alkali section and the weak alkali section is 1:1:2. The device operates continuously for 8 hours. Calculate the weight of the butter in the lye and measure the thickness of the butter layer on the tray. The amount of butter produced when no inhibitor is added and the thickness o...

Embodiment 2

[0035] Add 20g of sodium fatty acid methyl sulfonate, 10g of dodecyldimethylbenzylammonium chloride, 5g of nonylphenol polyoxyethylene ether, 30g of carbohydrazide, and 35g of deionized water into the reactor. After stirring for 1 hour at room temperature The cleaning agent is filtered and applied to the caustic washing tower of the ethylene plant. After 30 days of adding the cleaning agent, the polymerization inhibition efficiency is 98.3%.

Embodiment 3

[0037] Add 40g of sodium fatty acid methyl sulfonate, 8g of dodecyldimethylbenzylammonium chloride, 10g of nonylphenol polyoxyethylene ether, 28g of carbohydrazide, and 14g of deionized water into the reactor. After stirring for 1 hour at room temperature The cleaning agent is obtained by filtering, and the cleaning agent is applied to the caustic washing tower of the ethylene plant. After 30 days of adding the cleaning agent, the polymerization inhibition efficiency is 97.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com