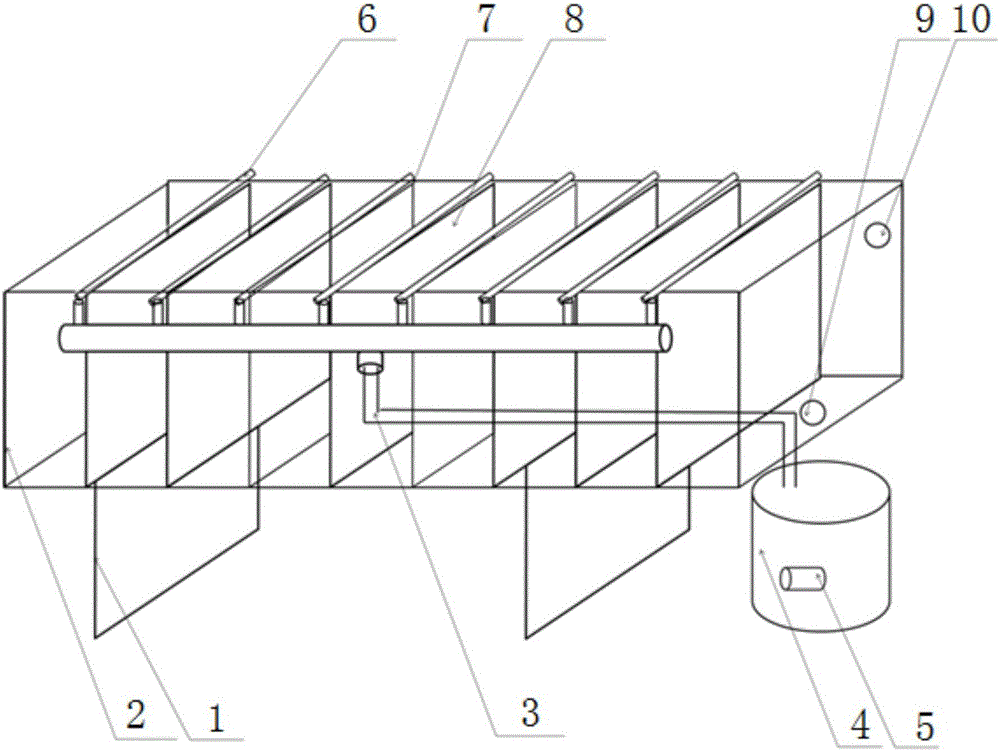

Relatively enclosed multi-thin layer adherent culture device for production of microalgae

An adherent culture and culture device technology, applied in enzymology/microbiology devices, biochemical cleaning devices, methods of supporting/immobilizing microorganisms, etc. Insufficient and other problems, to achieve the effect of increasing the biomass yield of microalgae, low energy consumption, and improving the efficiency of light energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

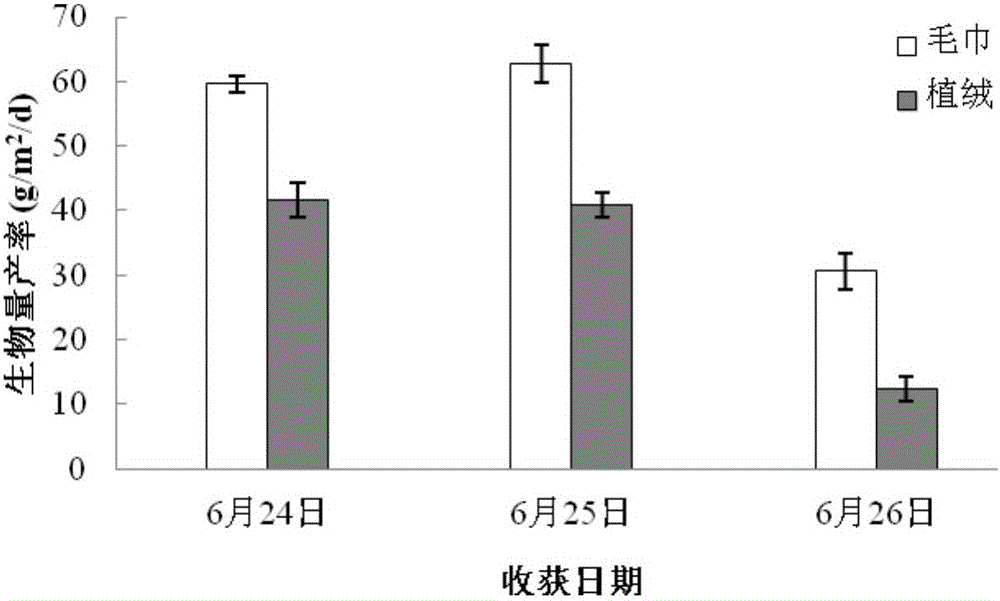

Embodiment 1

[0040] The test location is Qingdao, Shandong, and the test time is June 2015. The height of the support is 0.3 meters, and the height of the culture tank is 0.3 meters. Microfiber towels and flocking were chosen as flexible materials to support microalgae on the surface of adherent culture units. A total of 10 adherent culture units were set up in the culture device, including 5 microfiber towels and 5 flocking. Each adherent culture unit is 0.25 meters high and 0.3 meters wide, and the distance between adherent culture units is 0.05 meters. The spirulina is inoculated on the surface of the culture unit of the adherent culture device. The culture fluid in the culture medium storage tank is Zarrouk culture medium (consists of: every 1 liter of culture medium contains 2.5 grams of sodium nitrate, 0.5 grams of dipotassium hydrogen phosphate, 1 gram of sodium chloride, 0.2 grams of magnesium sulfate heptahydrate, sulfuric acid heptahydrate 0.01 g of ferrous iron, 1 g of potass...

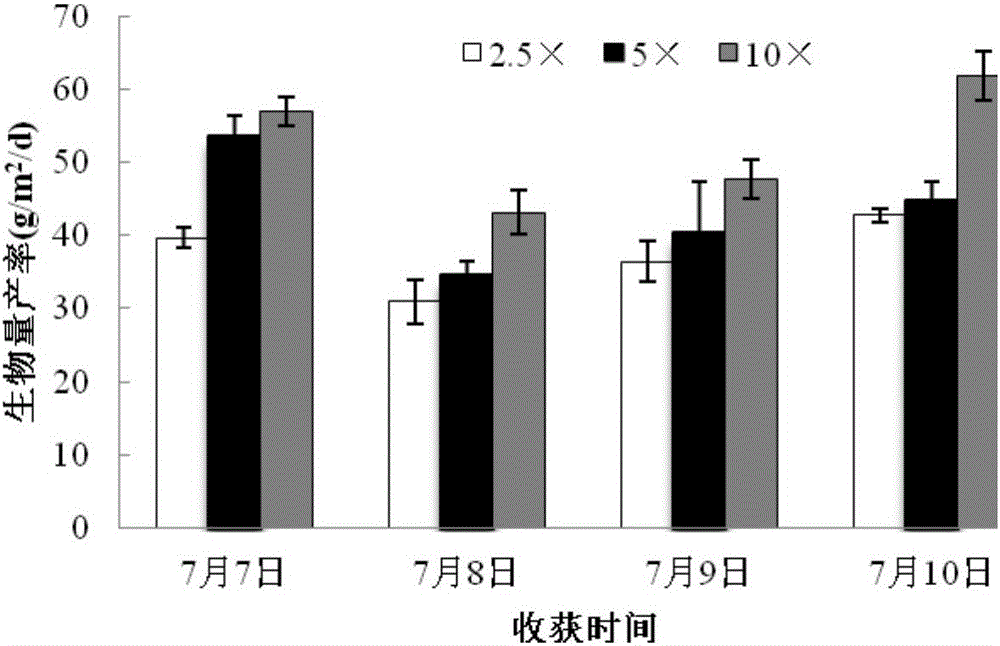

Embodiment 2

[0044] The test location is Qingdao, Shandong, and the test time is July 2015. The height of the support is 0.3 meters, and the height of the culture tank is 0.3 meters. Microfiber towels were chosen as the flexible material to support the microalgae on the surface of the adherent culture unit. A total of 12 adherent culture units are set up in the culture device, and each adherent culture unit is 0.25 meters high and 0.3 meters wide, of which 4 adherent culture units have a distance of 0.05 meters (light dilution factor 10×), and the other 4 adherent culture units The spacing is 0.1 m (light dilution factor 5×), and the spacing of the remaining 4 adherent culture units is 0.2 meter (light dilution factor 2.5×). The spirulina is inoculated on the surface of the culture unit of the adherent culture device. The culture fluid in the culture medium storage tank is Zarrouk culture medium (consists of: every 1 liter of culture medium contains 2.5 grams of sodium nitrate, 0.5 grams...

Embodiment 3

[0046] The test location is Qingdao, Shandong, and the test time is July 2015. The height of the support is 0.3 meters, and the height of the culture tank is 0.3 meters. Microfiber towels and flocking were chosen as flexible materials to support microalgae on the surface of adherent culture units. A total of 10 adherent culture units were set up in the culture device, including 5 microfiber towels and 5 flocking. Each adherent culture unit is 0.25 meters high and 0.3 meters wide, and the distance between adherent culture units is 0.05 meters. Inoculate the yellow hair algae (Tribonema sp.) on the surface of the culture unit of the adherent culture device. The culture fluid in the culture medium storage tank is BG11 culture medium (consists of: every 1 liter of culture medium contains 1.5 grams of sodium nitrate, 0.04 grams of dipotassium hydrogen phosphate, 0.0375 grams of magnesium sulfate heptahydrate, 0.036 grams of calcium chloride dihydrate, Citric acid 0.006g, ferric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com