Method for preparing efficient air water-collecting copper surface by virtue of gradient anodic oxidation method

An anodic oxidation method and high-efficiency air technology, applied in the field of interface chemistry, can solve the problems of scarcity of fresh water and low water collection efficiency, and achieve the effects of improved water collection efficiency, low product cost, and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

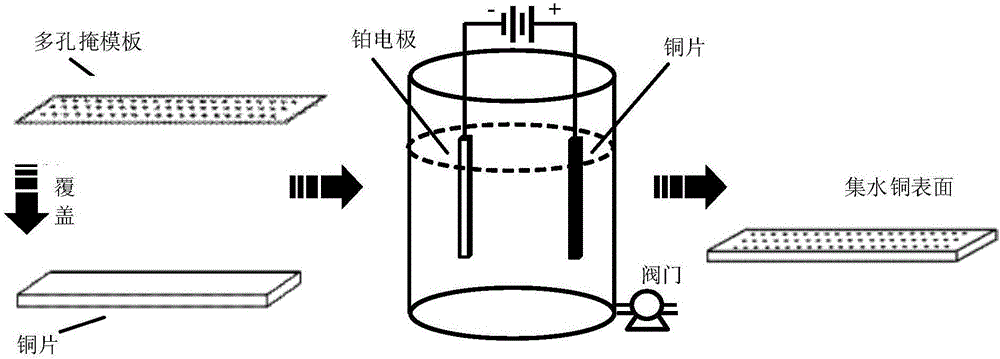

[0033] This embodiment provides a gradient anodic oxidation method to prepare a gradient-wettable hydrophilic-hydrophobic interphase copper surface with a relatively large hydrophilic region area ratio. The specific steps are:

[0034] The first step, the preparation of electrolyte:

[0035] Weigh 1g of sodium hydroxide particles, dissolve in 500g of deionized water, and stir until completely dissolved.

[0036] The second step, target sample surface pretreatment:

[0037] Cut the copper sheet into a rectangle with a length of 3.5cm and a width of 1.5cm, soak it in dilute hydrochloric acid for 15 minutes, then ultrasonically clean it with ethanol and water for 20 minutes, and dry it in a drying oven at 70°C for 10 minutes stand-by.

[0038] The third step is to prepare gradient wettable hydrophilic-hydrophobic interphase surface by anodic oxidation method:

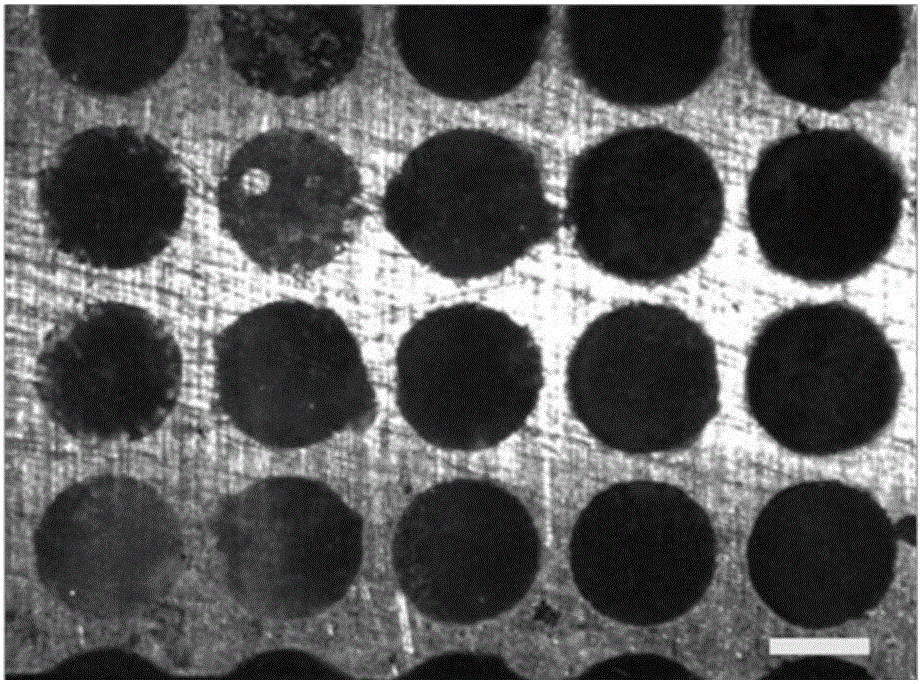

[0039] First, one side of the target sample is closely attached to the insulating porous mask. The hole diameter of t...

Embodiment 2

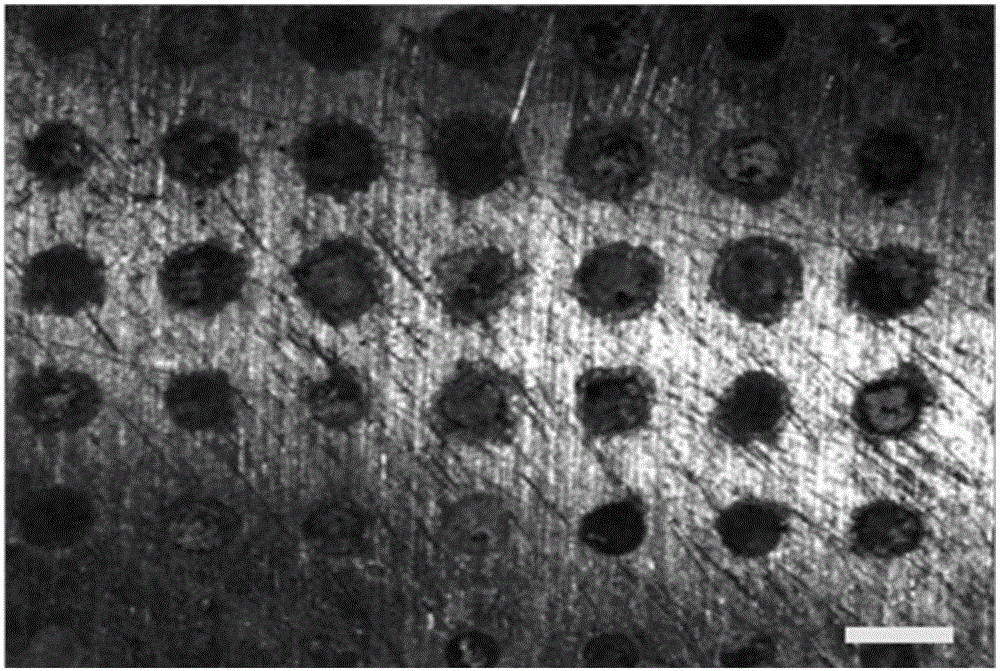

[0043] This embodiment provides a method for preparing a gradient-wettable hydrophilic-hydrophobic interphase copper surface with a smaller hydrophilic region area ratio by gradient anodic oxidation. The specific steps are:

[0044] The first step, the preparation of electrolyte:

[0045] Weigh 1g of sodium hydroxide particles, dissolve in 500g of deionized water, and stir until completely dissolved.

[0046] The second step, target sample surface pretreatment:

[0047] Cut the copper sheet into a rectangle with a length of 3.5cm and a width of 1.5cm, soak it in dilute hydrochloric acid for 15 minutes, then ultrasonically clean it with ethanol and water for 20 minutes, and dry it in a drying oven at 70°C for 10 minutes stand-by.

[0048] The third step is to prepare gradient wettable hydrophilic-hydrophobic interphase surface by anodic oxidation method:

[0049] First, one side of the target sample is closely attached to the insulating porous mask. The hole diameter of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com