Reflective laser differential confocal curvature radius measuring method and device

A differential confocal, radius of curvature technology, used in measuring devices, optical devices, instruments, etc., can solve problems such as harsh environmental conditions, shorten the length of guide rails, improve anti-environmental interference ability and system reliability, and improve measurement. The effect of speed and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

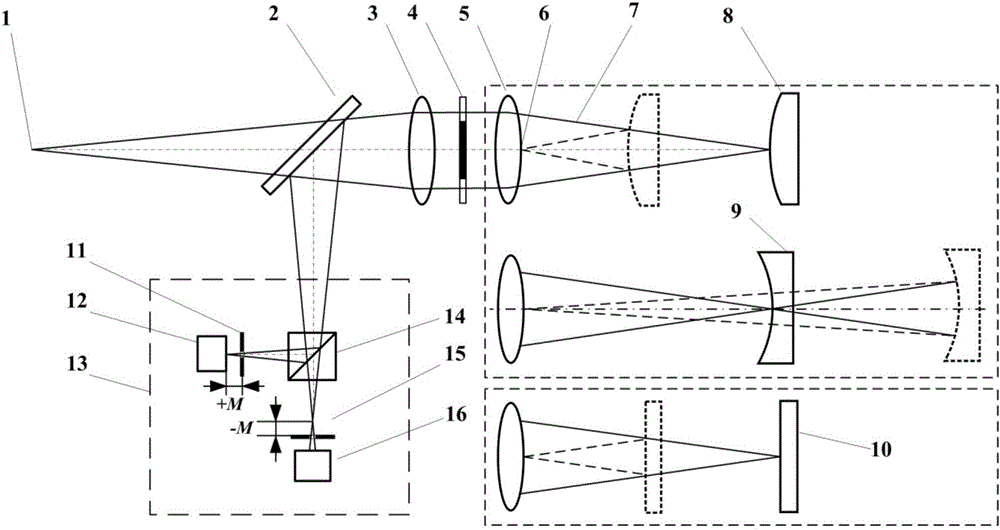

Method used

Image

Examples

Embodiment 1

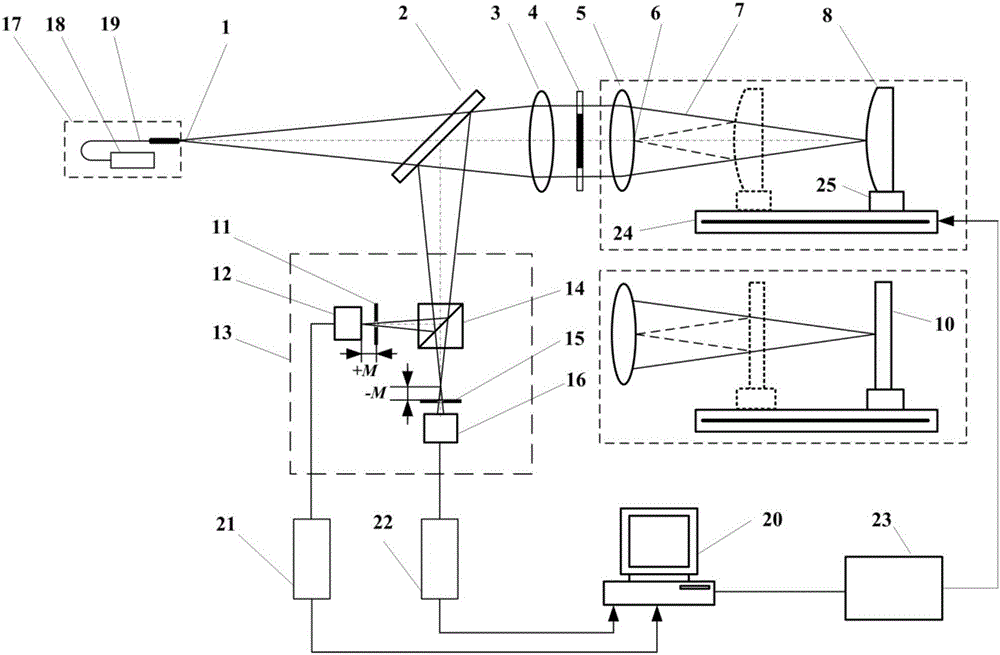

[0037] Such as figure 2 As shown, the embodiment of the present invention is based on figure 1 The schematic diagram of the reflective laser differential confocal radius of curvature measurement system shown can also include: point light source generating device 17, laser 18, optical fiber 19, main control computer 20, pre-focus detector image acquisition card 21, post-focus detection image acquisition card 22, electromechanical control device 23, linear translation guide rail 24, and adjustment frame 25; wherein, the point light source 1 can be composed of a laser 18 and an optical fiber 19; the differential confocal detection system 13 can be composed of a pre-focus light intensity detector 12, a focus Front pinhole 11, dichroic prism 14, back-focus pinhole 15 and back-focus light intensity detector 16 are formed;

[0038] Such as figure 2 As shown, the process of using the reflective laser differential confocal curvature radius measurement method to achieve high-precisi...

Embodiment 2

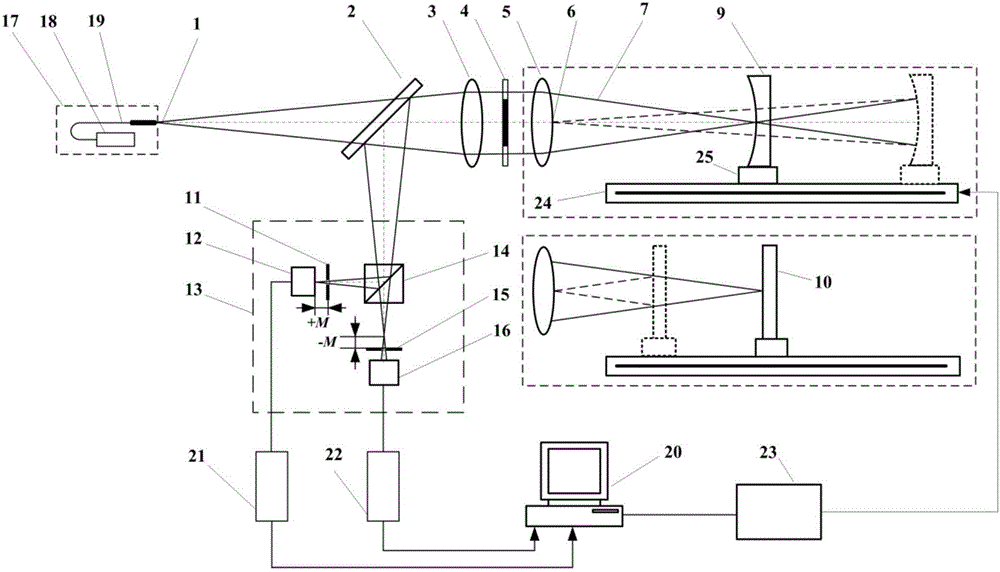

[0050] When measuring the measured concave mirror 9 with a curvature radius R≈-5000mm as an example, when the top focal length of the objective lens 5 is about 1045mm and the measurement aperture is 100mm, the reflective laser differential confocal curvature radius measurement device is as image 3 As shown, the measurement steps are:

[0051] Step 1. Place the measured concave mirror 9 in the measuring beam 7 behind the objective lens 5, and adjust the measured concave mirror 9 to be coaxial with the measuring beam 7;

[0052] Step 2, move the measured concave mirror 9 along the optical axis direction, when the measured concave mirror 9 is located near the focal point of the objective lens 5, move the measured concave mirror 9 to scan, and the image acquisition card 21 and the image acquisition card 22 collect the focal points respectively. The axial light intensity information of the front detector 12 and the back-focus detector 16 is differentially processed by the main con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com