Antipollution and antibacterial aromatic polyamide reverse osmosis composite membrane and preparation method

A technology of reverse osmosis composite membrane and aromatic polyamide, applied in the field of water treatment, can solve the problems of no universal applicability and different action mechanisms, and achieve the effect of mild conditions and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

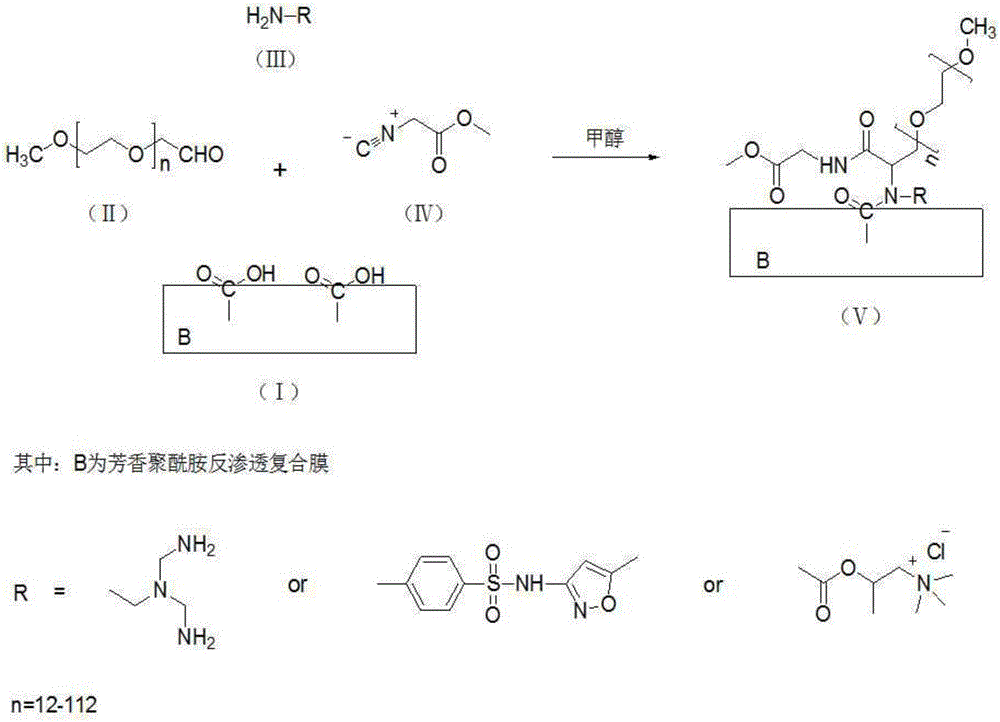

[0035] An anti-pollution antibacterial aromatic polyamide reverse osmosis composite membrane preparation method, including the following steps (see figure 1 ):

[0036] (1) Wash the same low-pressure and low-energy aromatic polyamide reverse osmosis composite membrane (I) as in Comparative Example 1 with isopropanol and deionized water in sequence, and air dry naturally without light;

[0037] (2) The area treated in step (1) is 4×20cm 2 The polyamide reverse osmosis composite membrane is immersed in methanol, and 1mmol of hydroxyl-terminated aldehyde-terminated polyethylene glycol monomethyl ether (weight average molecular weight is 2000) (II), 1mmol sulfamethoxazole (III) and 1mmol iso Methyl cyanoacetate (IV), stirred at 25°C for 12h;

[0038] (3) Wash with deionized water to obtain anti-pollution and antibacterial aromatic polyamide reverse osmosis composite membrane.

Embodiment 2

[0040] A preparation method of anti-pollution and antibacterial aromatic polyamide reverse osmosis composite membrane includes the following steps:

[0041] (1) Same as step (1) of Example 1;

[0042] (2) The area treated in step (1) is 4×20cm 2 The polyamide reverse osmosis composite membrane was soaked in methanol, and 1mmol of hydroxyl-terminated aldehyde-terminated polyethylene glycol monomethyl ether (weight average molecular weight of 600), 1mmol sulfamethoxazole and 1mmol methyl isocyanoacetate were added in sequence. Stir at 25°C for 1h;

[0043] (3) Same as step (3) of Example 1.

Embodiment 3

[0045] A preparation method of anti-pollution and antibacterial aromatic polyamide reverse osmosis composite membrane includes the following steps:

[0046] (1) Same as step (1) of Example 1;

[0047] (2) The area treated in step (1) is 4×20cm 2 The polyamide reverse osmosis composite membrane is soaked in methanol, and 1mmol of hydroxyl-terminated aldehyde-formulated polyethylene glycol monomethyl ether (weight average molecular weight is 2000), 1mmol of tris-(2-aminoethyl)amine and 1mmol of isocyanide are sequentially added Methyl ethyl acetate, stirring at 25°C for 18h;

[0048] (3) Same as step (3) of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com