Environment-friendly soft polyvinyl chloride granules

A soft polyvinyl chloride and polyvinyl chloride resin technology, applied in the field of polyvinyl chloride pellet composition, can solve the problems of product performance deterioration, environmental pollution, loss of use value, etc., achieve good protection and safety, plasticization The effect of high efficiency and excellent toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

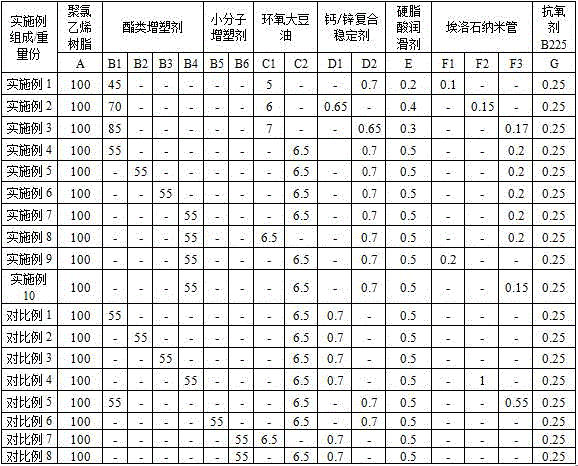

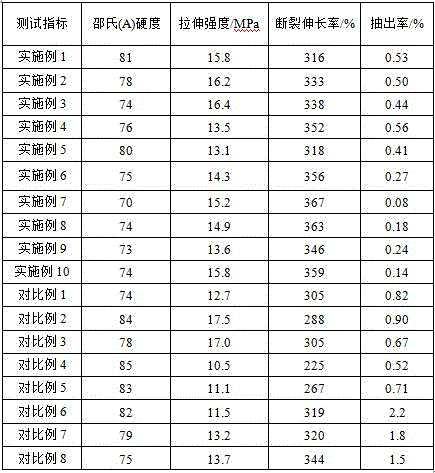

[0079] Embodiment 1, an environment-friendly soft polyvinyl chloride granule, calculated by weight, its preparation raw materials include: 100 parts of polyvinyl chloride resin; 30-130 parts of ester plasticizer; 5-10 parts of epoxy soybean oil 0.1-2 parts of calcium / zinc composite stabilizer; 0.1-1 part of lubricant; 0.01-0.5 parts of halloysite nanotubes.

Embodiment approach 2

[0080] Embodiment 2, an environment-friendly soft polyvinyl chloride granule, calculated by weight, its preparation raw materials include: 100 parts of polyvinyl chloride resin; 40-80 parts of ester plasticizer; 5-10 parts of epoxy soybean oil 0.3-0.8 parts of calcium / zinc composite stabilizer; 0.2-0.5 parts of lubricant; 0.05-0.5 parts of halloysite nanotubes.

Embodiment approach 3

[0081] Embodiment 3, an environment-friendly soft polyvinyl chloride granule, calculated by weight, its preparation raw materials include: 100 parts of polyvinyl chloride resin; 55 parts of ester plasticizer; 6.5 parts of epoxidized soybean oil; calcium / 0.6-0.7 parts of zinc composite stabilizer; 0.5 parts of lubricant; 0.1-0.2 parts of halloysite nanotubes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com