Energy-storage and luminous ceramic coating and preparation method thereof

A technology of energy storage luminescent ceramics and energy storage luminescent powder, which is applied in the fields of traffic safety facilities and new materials to achieve the effects of no complicated procedures, simple production process and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] An energy-storage luminescent ceramic coating is characterized in that it is composed of three components, including the following raw materials in parts by weight:

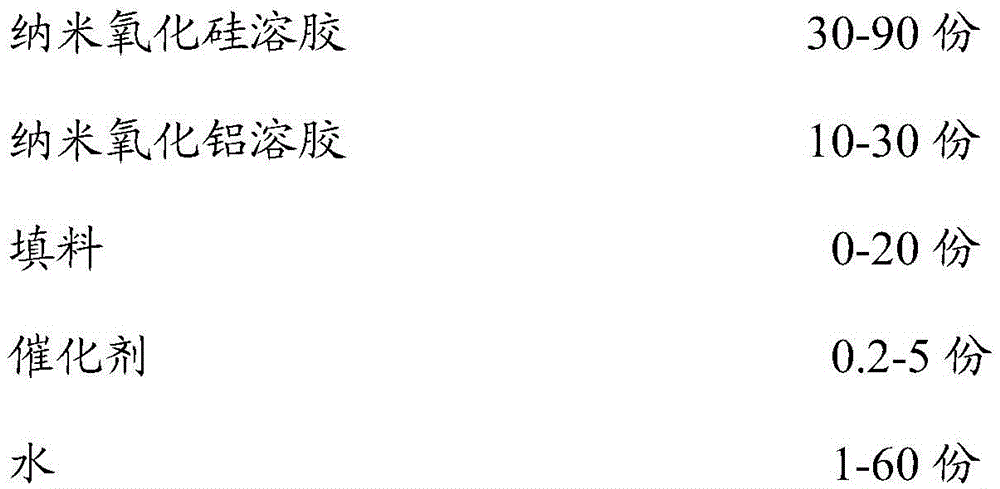

[0038] A component:

[0039]

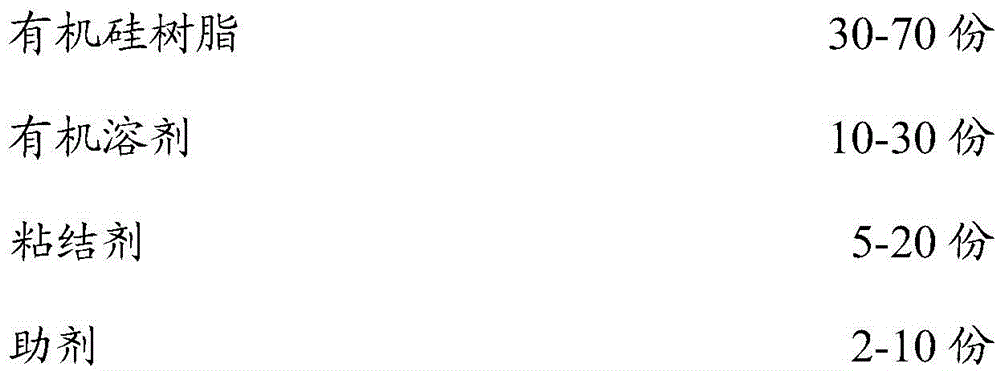

[0040] B component:

[0041]

[0042]

[0043] C component

[0044] Energy storage luminous powder 50 parts

[0045] 1 part of solvent.

Embodiment 2

[0047] An energy-storage luminescent ceramic coating is characterized in that it is composed of three components, including the following raw materials in parts by weight:

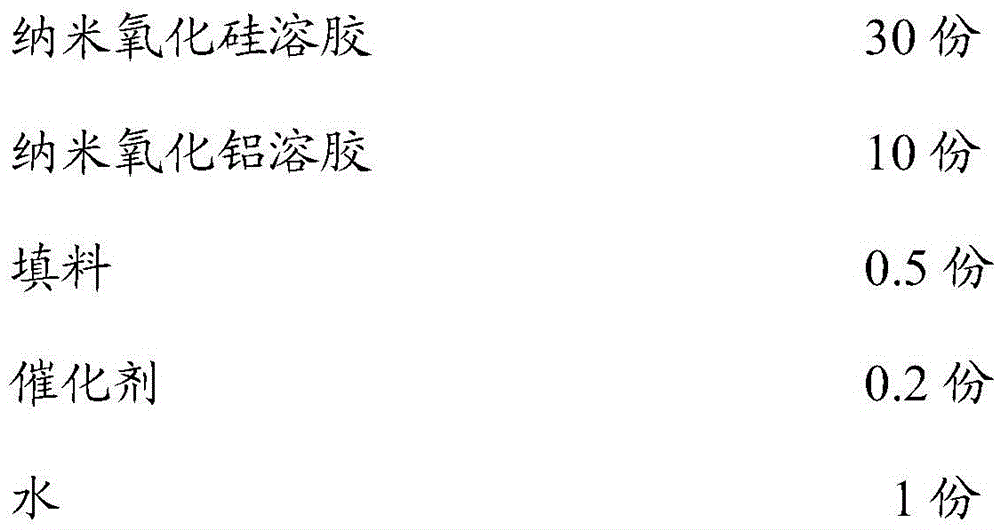

[0048] A component:

[0049]

[0050] B component:

[0051]

[0052] C component

[0053] Energy storage luminous powder 70 parts

[0054] 20 parts of solvent.

Embodiment 3

[0056] An energy-storage luminescent ceramic coating is characterized in that it is composed of three components, including the following raw materials in parts by weight:

[0057] A component:

[0058]

[0059] B component:

[0060]

[0061] C component

[0062] Energy storage luminous powder 90 parts

[0063] 50 parts of solvent.

[0064] Wherein, in embodiment 1-3:

[0065] The concentration of the nano-silica sol and the nano-alumina sol is 1-30%, and the particle size is 20-60nm.

[0066] The filler is one or more combinations of quartz, mica powder, talcum powder, kaolin and titanium dioxide.

[0067] The catalyst is an acid-base regulator, which is one or more combinations of glacial acetic acid, formic acid, acetic acid, stearic acid and oleic acid.

[0068] The silicone resin is one or more modified resins of methoxytrichlorosilane, dimethyldichlorosilane and phenyltrichlorosilane.

[0069] The adhesive is formed by mixing one or more of methyl methacryla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com