Hot-pressed masking tape

A technology of masking paper and tape, applied in the directions of adhesives, adhesive types, film/sheet adhesives, etc. Good toughness, good tensile effect, good retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

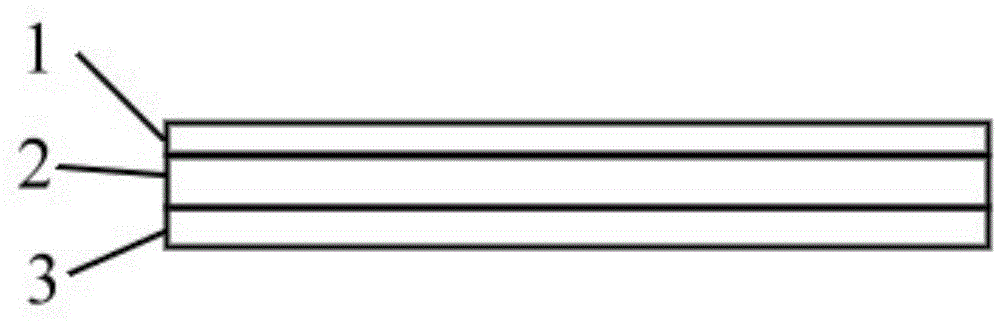

[0023] Such as figure 1 As shown, the masking paper heat-pressing tape provided by the present invention has a masking paper layer 1, a polyurethane adhesive layer 2, and a hot-melt adhesive layer 3 in sequence from top to bottom. The formula of the polyurethane adhesive layer is: 380 parts of polyester polyol; 30 parts of sodium sulfamate; 2.5 parts of dibutyltin dilaurate; 100 parts of isocyanate; 15 parts of ethylenediamine; 800 parts of water. The formula of the hot-melt adhesive layer is: 250 parts of ethylene-vinyl acetate copolymer, the content of vinyl acetate monomer is 20%, and its MI value is 350; 35 parts of petroleum resin; tetrakis (3,5-di-tert-butyl 2 parts of -4-hydroxyl) pentaerythritol phenylpropionate. The thickness of the textured paper layer is 100 μm; the thickness of the polyurethane adhesive layer is 8 μm; the thickness of the hot melt adhesive layer is 12 μm. The masking paper heat-pressing tape of the present invention will not produce residual glue...

Embodiment 2

[0025] Such as figure 1 As shown, the masking paper heat-pressing tape provided by the present invention has a masking paper layer 1, a polyurethane adhesive layer 2, and a hot-melt adhesive layer 3 in sequence from top to bottom. The formula of the polyurethane adhesive layer is: 400 parts of polyester polyol; 25 parts of sodium sulfamate; 1 part of dibutyltin dilaurate; 128 parts of isocyanate; 25 parts of ethylenediamine; The formula of the hot melt adhesive layer is: 200 parts of ethylene-vinyl acetate copolymer, the content of vinyl acetate monomer is 20%, and its MI value is 350; 50 parts of petroleum resin; tetrakis (3,5-di-tert-butyl -4 parts of pentaerythritol phenylpropionate. The thickness of the textured paper layer is 120 μm; the thickness of the polyurethane adhesive layer is 5 μm; the thickness of the hot melt adhesive layer is 15 μm. The masking paper heat-pressing tape of the present invention will not produce residual glue after peeling off.

Embodiment 3

[0027] Such as figure 1 As shown, the masking paper heat-pressing tape provided by the present invention has a masking paper layer 1, a polyurethane adhesive layer 2, and a hot-melt adhesive layer 3 in sequence from top to bottom. The formula of the polyurethane adhesive layer is: 350 parts of polyester polyol; 20 parts of sodium sulfamate; 3 parts of dibutyltin dilaurate; 82 parts of isocyanate; 10 parts of ethylenediamine; The formula of the hot-melt adhesive layer is: 320 parts of ethylene-vinyl acetate copolymer, the content of vinyl acetate monomer is 20%, and its MI value is 350; 21 parts of petroleum resin; tetrakis (3,5-di-tert-butyl 0.5 parts of -4-hydroxy) pentaerythritol phenylpropionate. The thickness of the textured paper layer is 80 μm; the thickness of the polyurethane adhesive layer is 6 μm; the thickness of the hot melt adhesive layer is 10 μm. The masking paper heat-pressing tape of the present invention will not produce residual glue after peeling off.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com