Low-temperature gel breaker and preparation method thereof

A gel breaker and low-temperature technology, which is applied in the field of low-temperature gel breaker and its preparation, can solve the problems such as the reduction of the gel breaking effect, and achieve the effect of complete gel breaking, rapid gel breaking, and convenient on-site construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Prepare the materials according to the formula in Table 1, first put the peroxide and coagent into the reaction kettle, then add water, turn on the stirring device in the kettle, and stir for 30 to 50 minutes to obtain the finished product.

[0028] or follow the steps below:

[0029] (1), take each raw material component by weight ratio, first put peroxide into the reactor, then add water, then add sodium gluconate, stir for 30 minutes;

[0030] (2), add potassium iodide, hexamethylenetetramine, triethanolamine successively, continue stirring for 60 minutes to obtain the finished product.

[0031] In actual engineering, the second preparation process is preferred.

[0032] Table 1 embodiment weight part formula

[0033]

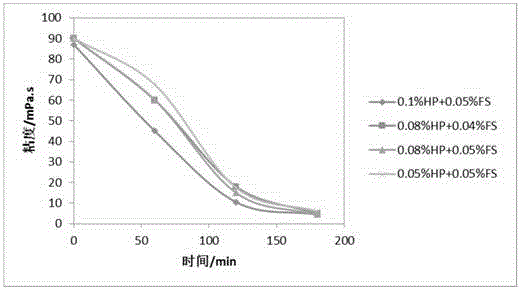

[0034] Low-temperature gel breaker of the present invention, its performance test see figure 1 , the experimental temperature is 20°C, from figure 1 It can be seen that the structure of polymer fracturing fluid and guar gum fracturing fluid can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com