Aluminum gallate-based fluorescent material and preparation method thereof

A fluorescent material, aluminum gallate technology, applied in the field of aluminum gallate-based fluorescent materials and its preparation, can solve the problems of low production efficiency, emission spectrum drift, harsh synthesis conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

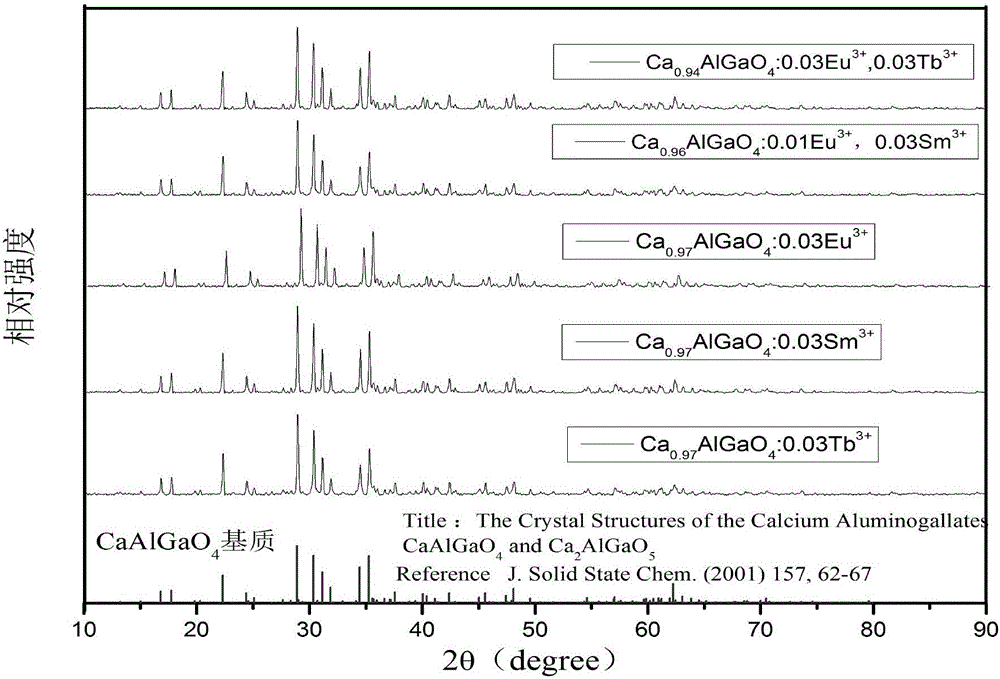

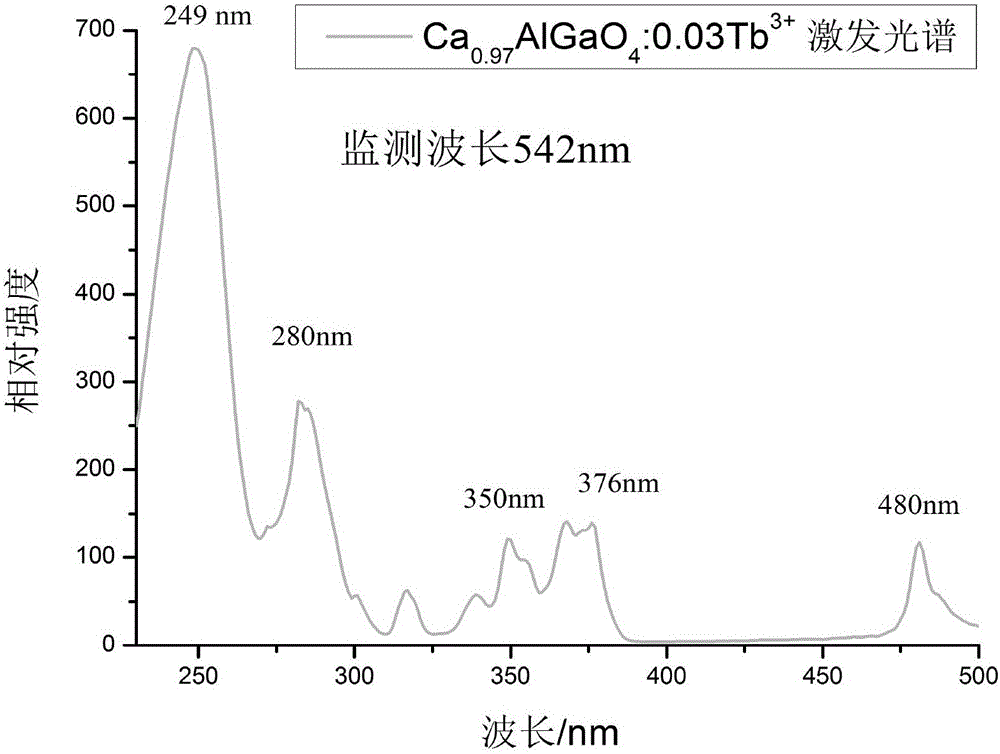

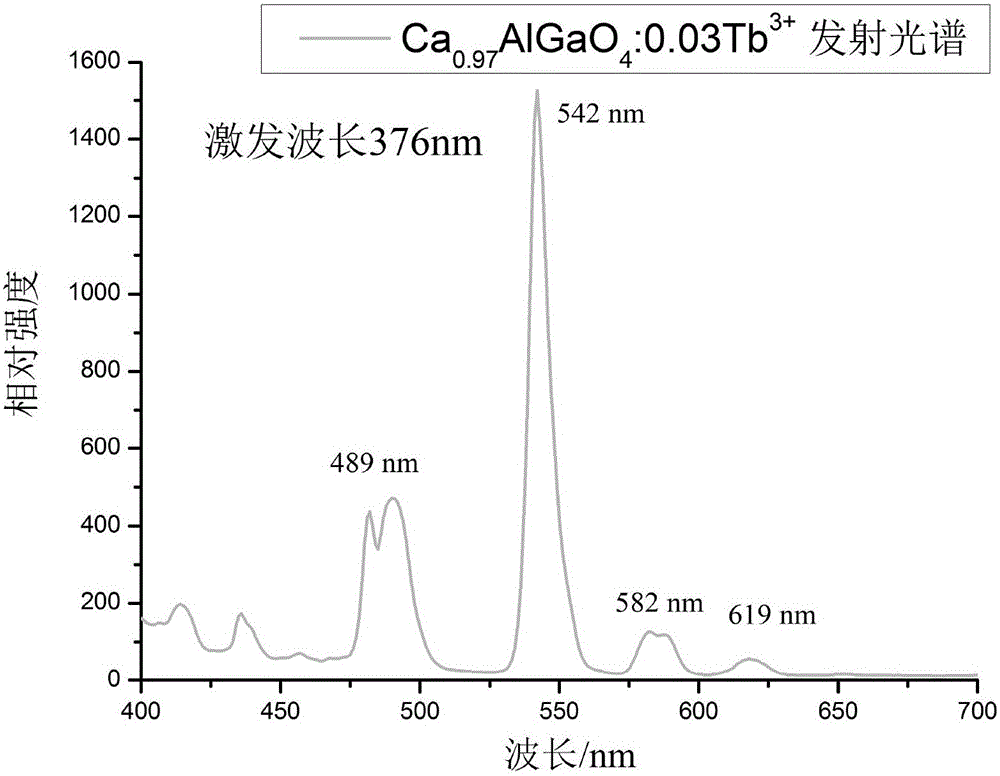

[0033] The chemical formula of the aluminum gallate-based green fluorescent material prepared in this example is: Ca 0.97 AlGaO 4 :0.03Tb 3+ .

[0034] Weigh raw material CaCO 3 1.9612g, Al 2 o 3 1.0196g, Ga 2 o 3 1.8744g and Tb 4 o 7 Put 0.1120g into an agate mortar, grind it sufficiently to pulverize and mix evenly to obtain a mixture, then put the mixture into a corundum crucible, place it in a tube furnace for calcination, keep it at 1250°C for 8 hours, and heat up The rate is 2-10°C / min, and the entire calcination process is carried out in an air atmosphere. After the heat preservation is completed, it is cooled to room temperature, and then taken out and ground until the particle size reaches 3-60 μm to obtain a finished aluminum gallate-based green fluorescent material.

[0035] From figure 2 It can be seen that the excitation peak of the aluminum gallate-based green fluorescent material prepared in this example is located at 230nm-500nm, and its main excitat...

Embodiment 2

[0038] The chemical formula of the aluminum gallate-based red fluorescent material prepared in this example is: Ca 0.97 AlGaO 4 :0.03Eu 3+ .

[0039] Weigh raw material CaCO3 1.9612g, Al 2 o 3 1.0196g, Ga 2 o 3 1.8744g and Eu 2 o 3 Put 0.1055g into an agate mortar, grind it sufficiently to pulverize and mix evenly to obtain a mixture, then put the mixture into a corundum crucible, place it in a tube furnace for calcination, and keep it at 1400°C for 5 hours, the heating rate The temperature is 2-10°C / min. The whole calcination process is carried out in a weak oxidizing atmosphere. After the heat preservation is completed, it is cooled to room temperature, and then it is taken out and ground until the particle size reaches 3-60 μm, and the finished product of aluminum gallate-based red fluorescent material is obtained.

[0040] From Figure 4 It can be seen that the excitation peak of the alumino-gallate-based red fluorescent material prepared in this example is locate...

Embodiment 3

[0043] The chemical formula of the aluminum gallate-based orange fluorescent material prepared in this example is: Ca 0.97 AlGaO 4 :0.03Sm 3+ .

[0044] Weigh raw material CaCO 3 1.9612g, Al 2 o 3 1.0196g, Ga 2 o 3 1.8744g and Sm 2 o 3 Put 0.1051g into an agate mortar, grind it sufficiently to pulverize and mix it evenly to obtain a mixture, then put the mixture into a corundum crucible, place it in a tube furnace for calcination, and keep it at 1350°C for 7 hours, the heating rate The temperature is 2-10°C / min, and the whole calcination process is carried out in an air atmosphere. After the heat preservation is completed, it is cooled to room temperature, and then taken out and ground until the particle size reaches 3-60 μm, and the finished product of alumino-gallate-based orange fluorescent material is obtained.

[0045] From Figure 6 It can be seen that the excitation peak of the alumino-gallate-based orange fluorescent material prepared in this example is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com