Co-production method for extracting idesia polycarpa oil and idesia polycarpa whitening essence with multi-enzymatic and wet processes

A whitening agent and oil technology, which is applied in the direction of oil/fat production, oil/fat refining, fat production, etc., can solve the problems of Jatropha jatropha oil consumption time, no simultaneous extraction, bitter taste of oil, etc., and achieve high production added value and economic benefits, reduce energy consumption, and facilitate the preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

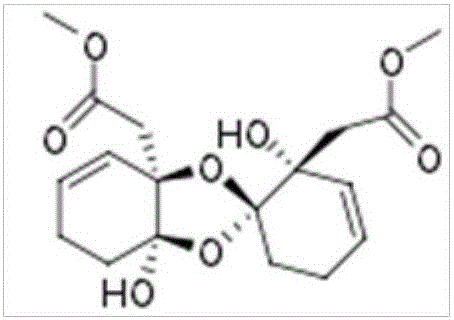

Image

Examples

Embodiment 1

[0026] Embodiment 1: A kind of multi-enzyme method wet method extracts the co-production method of Jatropha oil and Jatropha tomentosa whitening element, it comprises the following steps:

[0027] S1. Pretreatment: remove the fruit stalk and impurities of the fresh Jatropha tomentosa fruit and then crush it until the particle size of the slag is ≤2cm;

[0028] S2. Boiling: adding water to the slag to boil, the boiling time is 25min to obtain the slag mixture;

[0029] S3. Enzymolysis: Add neutral protease, pectinase, cellulase and carboxymethyl cellulose after the slag mixture is cooled to 50°C, the concentration of the neutral protease is 350U / ml, and the concentration of pectinase is 480U / ml, the concentration of cellulase is 170U / ml, the addition of carboxymethylcellulose is 0.1% of the weight of the debris mixture, and the pH value of the mixed solution is adjusted to 6 by citric acid with a mass percent concentration of 0.5%. Enzymolysis at 45°C for 1.5h;

[0030] S4. C...

Embodiment 2

[0036] Embodiment 2: A multi-enzyme wet extraction method for co-production of Jatropha oil and Jatropha tomentosa whitening element, which comprises the following steps:

[0037] S1. Pretreatment: remove the fruit stalk and impurities of the fresh Jatropha tomentosa fruit and then crush it until the particle size of the slag is ≤2cm;

[0038] S2. Boiling: adding water to the slag and boiling, the boiling time is 35min to obtain the slag mixture;

[0039] S3. Enzymolysis: Add neutral protease, pectinase, cellulase and carboxymethyl cellulose after the slag mixture is cooled to 60°C, the concentration of the neutral protease is 450U / ml, and the concentration of pectinase is 550U / ml, the concentration of cellulase is 230U / ml, the addition of carboxymethylcellulose is 0.3% of the weight of the debris mixture, and the pH value of the mixed solution is adjusted to 7 by the sodium citrate of 0.5% by mass percent concentration. , Enzymolysis at 55°C for 2.5h;

[0040] S4. Centrifug...

Embodiment 3

[0046] Embodiment 3: A kind of multi-enzyme method wet extraction method for co-production of Jatropha oil and Jatropha Jatropha whitening element, it comprises the following steps:

[0047] S1. Pretreatment: remove the fruit stalk and impurities of the fresh Jatropha tomentosa fruit and then crush it until the particle size of the slag is ≤2cm;

[0048] S2. Boiling: adding water to the slag to boil, the boiling time is 28min to obtain the slag mixture;

[0049] S3. Enzymolysis: Add neutral protease, pectinase, cellulase and carboxymethyl cellulose after the slag mixture is cooled to 54°C, the concentration of the neutral protease is 400U / ml, and the concentration of pectinase is 510U / ml, the concentration of cellulase is 200U / ml, the addition of carboxymethyl cellulose is 0.2% of the weight of the debris mixture, and the pH value of the mixed solution is adjusted to 6.5 by citric acid with a mass percent concentration of 0.5%. Enzymolysis at 48°C for 1.8 hours;

[0050] S4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com