Segment composite structure in water-rich formation and its construction method

A water-rich stratum and composite structure technology, which is applied in the direction of earth drilling, underground chambers, shaft equipment, etc., can solve the problems that the waterproof effect of the secondary lining cannot be expected, and the lining is prone to water leakage and cracks, so as to protect the surface Ecosystem, mitigation of soil erosion, reduction of damage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

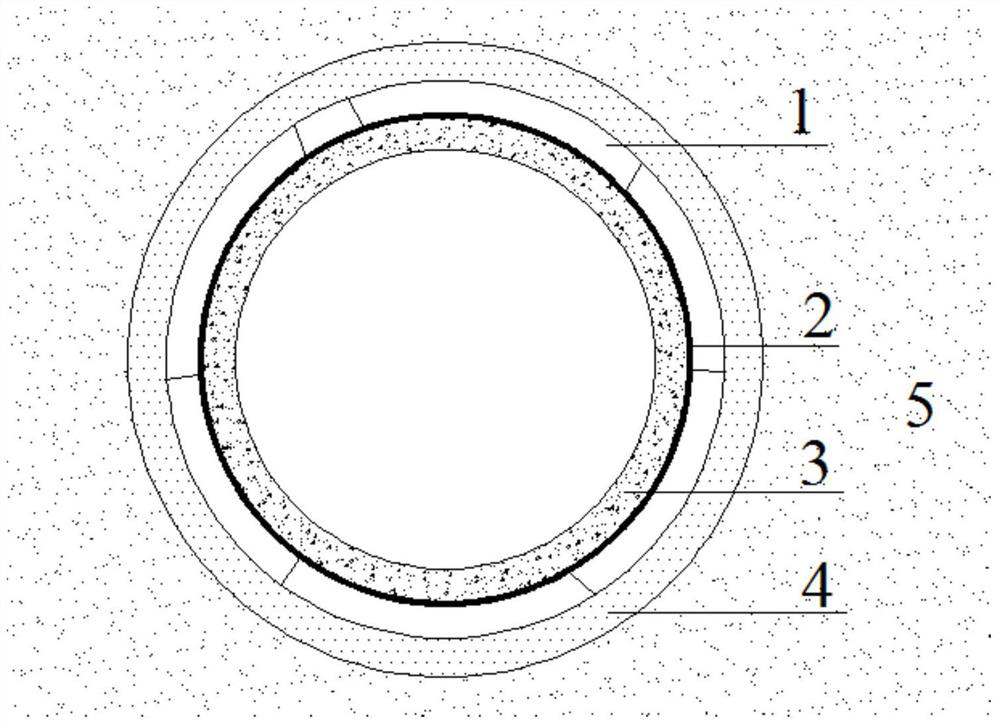

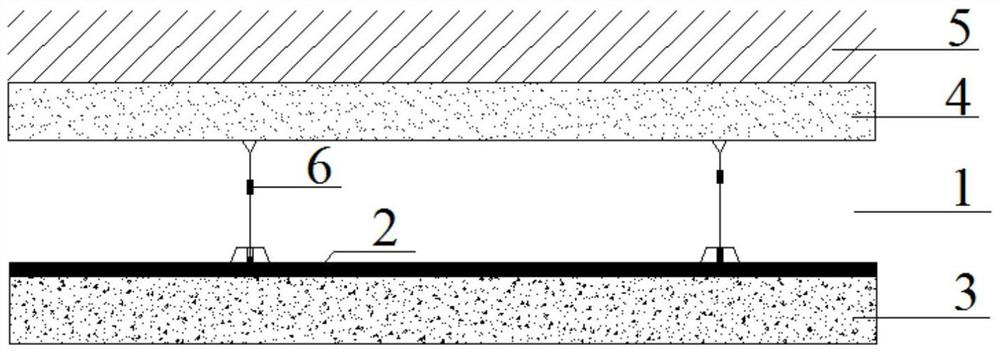

[0035] Such as figure 1 As shown, the special segment combination structure in water-rich formation includes segment structure 1, secondary lining concrete 3, waterproof board 2 and permeable grouting material 4 around the segment.

[0036] Among them, the construction joints in the segment structure 1 are provided with rubber waterstop strips 6, which are processed into closed rectangular frame strips in the factory according to the actual size of the waterstop grooves of each segment. It is inserted into the water-stop groove of the segment, and after assembly, each segment squeezes the rubber water-stop strip 6 mutually to achieve the purpose of water-stop. In order to increase the rubber compression and improve the water-stop effect, the cross-section of the rubber strip ado...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com