Infrared optical thin film protective film and preparation method thereof

An infrared optics, protective film technology, applied in optics, optical components, ion implantation coating, etc., can solve problems such as increasing the difficulty of preparation, increasing operating costs, film cracking or peeling, etc., to achieve high hardness, cost reduction, coating low temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

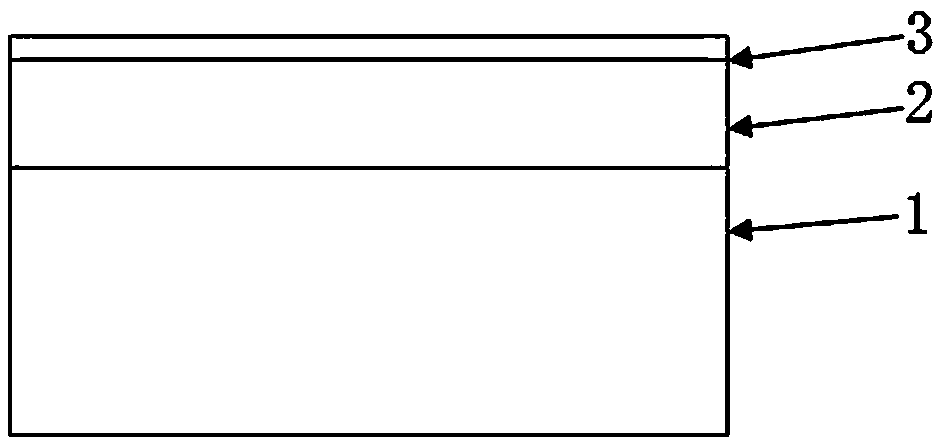

[0022] Example: such as figure 1 As shown, the infrared optical protective film 3 in this embodiment is coated on the outer layer of the multilayer infrared optical film 2 to protect the infrared optical film. A multilayer infrared optical film is plated on the substrate 1, where the substrate is a silicon substrate.

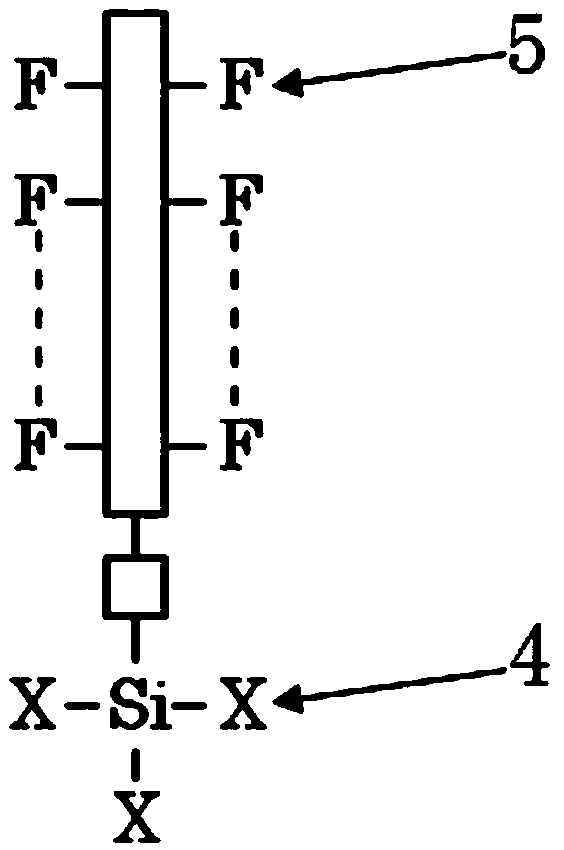

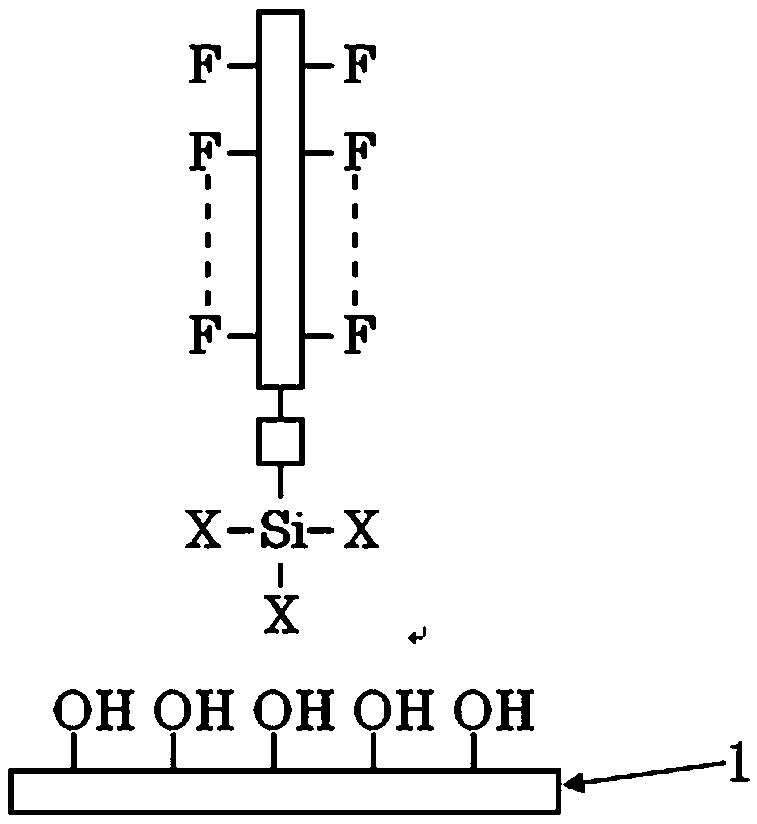

[0023] The protective film 3 in this embodiment uses fluorine-containing silane and its polymer. Such as figure 2 As shown, the fluorine-containing silane and its polymer have a silane 4 which is a hydrolyzable group and a fluoroalkane part 5 which is a non-hydrolyzable group. When the fluorine-containing silane and its polymer are used as the protective film 3 to be coated on the outer side of the multilayer infrared optical film 2, the fluorine-containing silane and its polymer and the coated substrate 1 Figure 3 to Figure 4 The chemical reaction shown; specifically, silane 4 can shrink reaction with the hydroxyl group on the coated substrate 1 and be combined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com