Laser display system

A technology of laser display and laser light source, applied in the field of laser, can solve the problems of low luminous flux and efficiency of red light, and achieve the effect of solving the problem of light color cast, improving stability and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

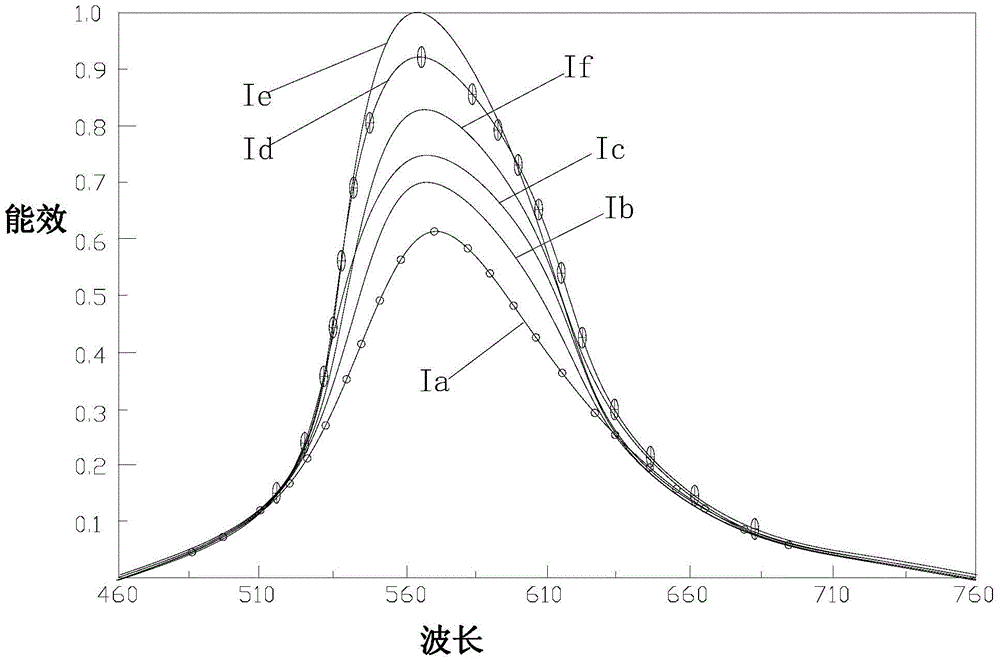

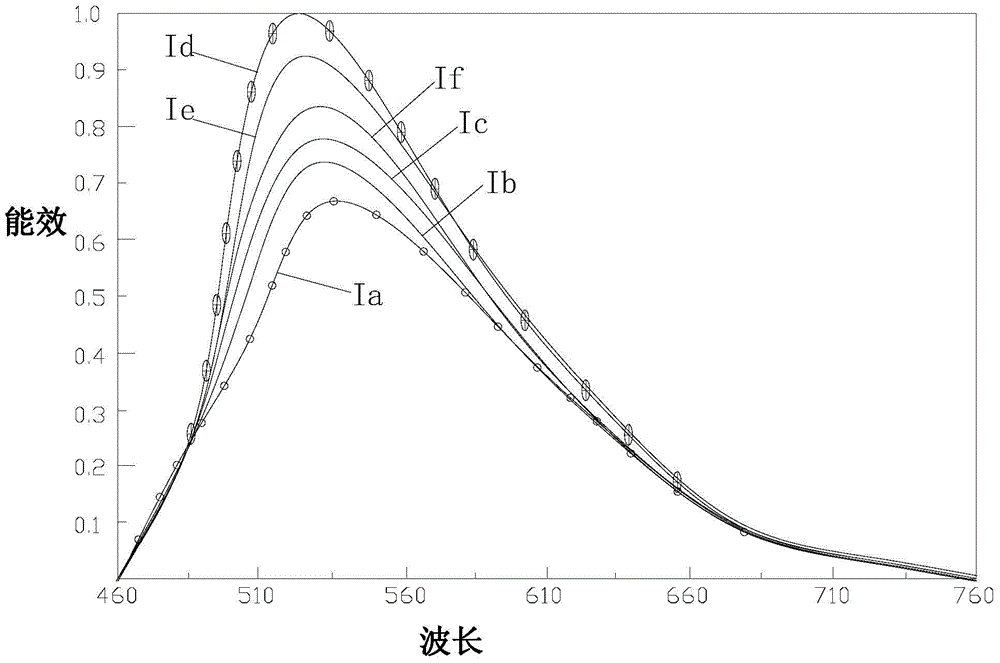

[0021] Embodiment By simultaneously coating yellow, green, and red three-color fluorescent powder layer color segments on the fluorescent wheel, and adjusting the driving current of the blue laser light source module to irradiate the fluorescent powder layer of different colors on the fluorescent color wheel in real time, the problem of laser light is solved. It shows the problem of light color cast after the product is used.

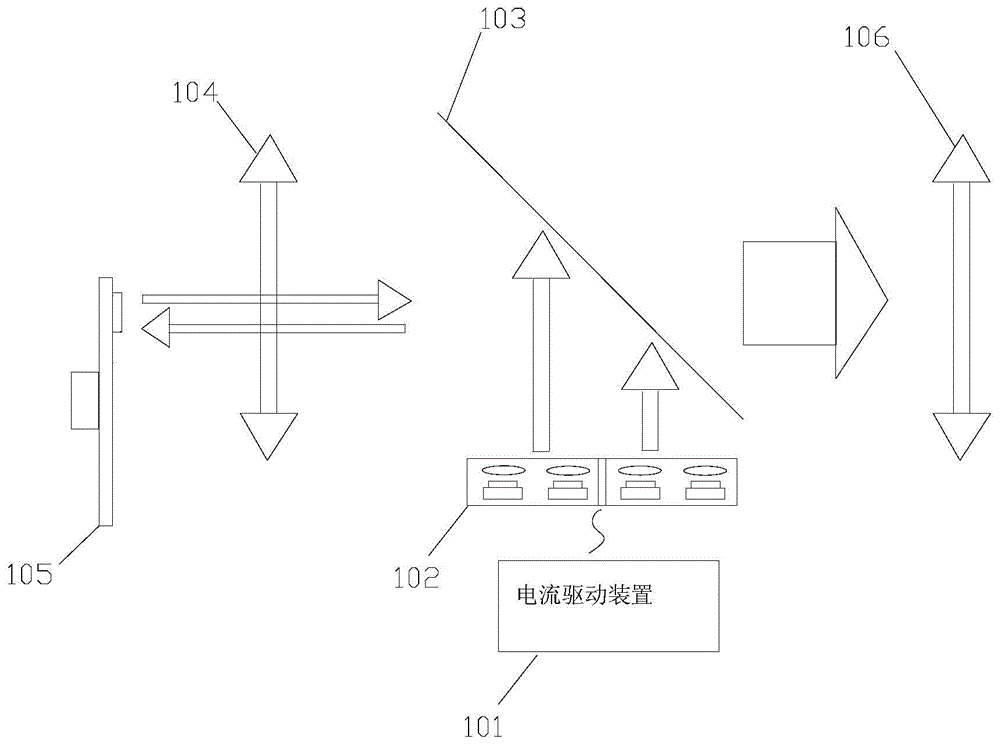

[0022] see figure 1 , this embodiment includes: a current drive device 101, a laser light source module 102, a fluorescent wheel 105, a light combining mirror 103, an optical lens 106 assembled in front of the fluorescent wheel 105, and at least one optical alignment component 104. Wherein, the fluorescent wheel 105 is used as the color conversion device of the system, including a substrate and a phosphor layer coated on the substrate in a ring; the optical lens 106 is used to converge the light generated by the excited phosphor layer; The optical coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com