Metal/air battery pack

An air battery pack and metal technology, applied to battery pack components, circuits, electrical components, etc., can solve problems such as difficult sealing, cumbersome drainage process, short circuit of the battery pack, etc., and achieve the effect of improving recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

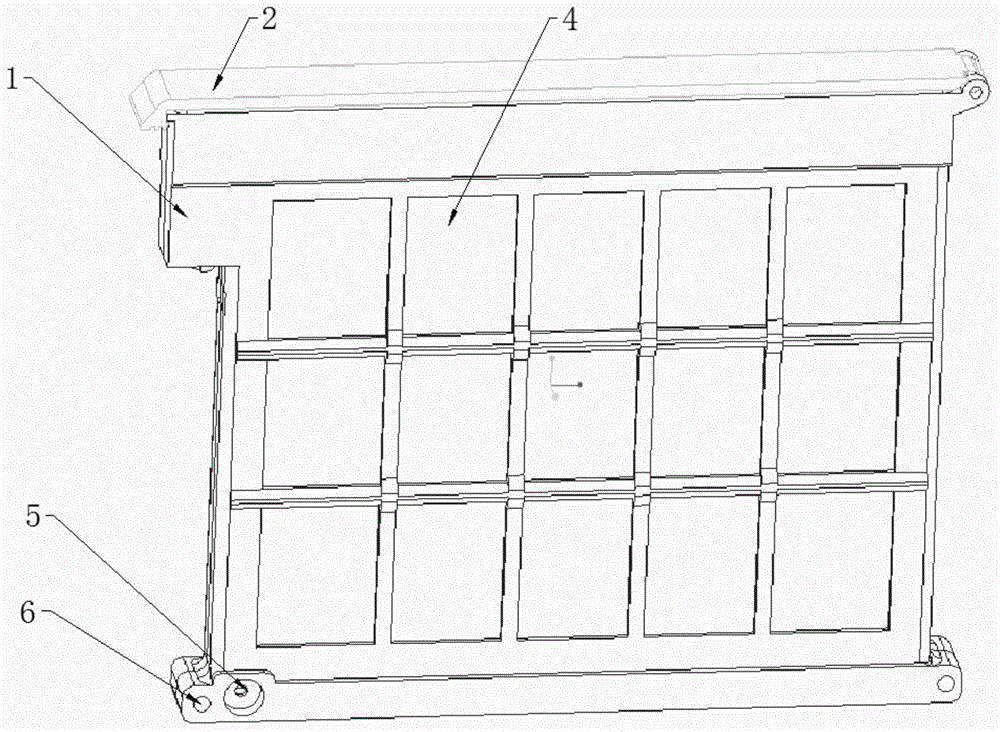

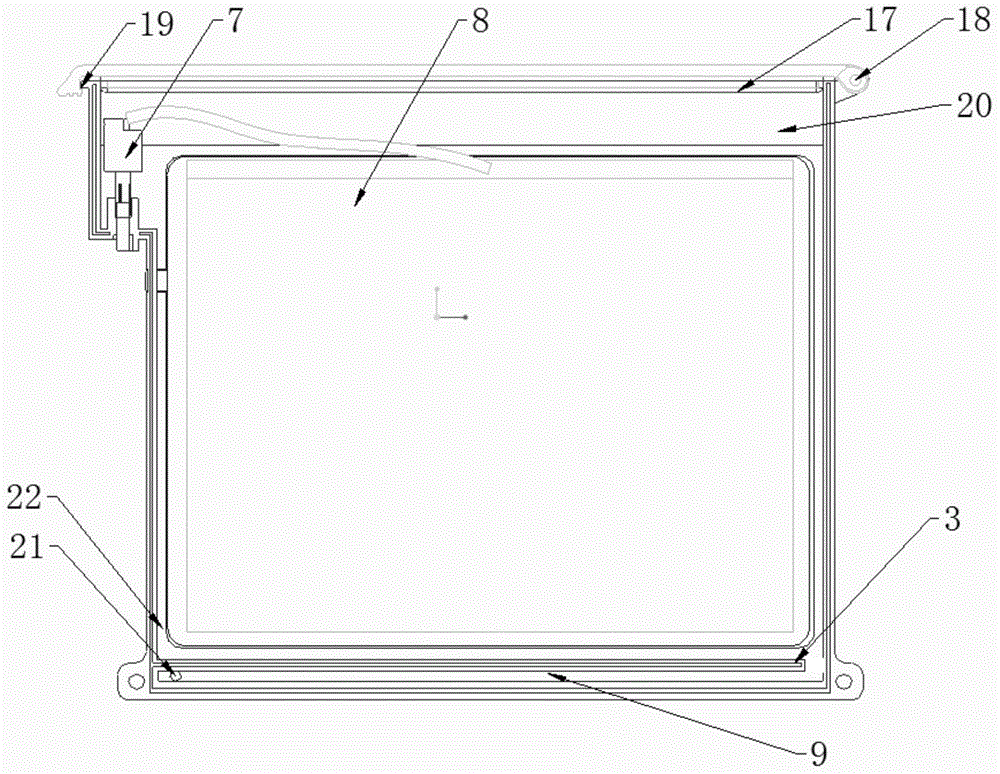

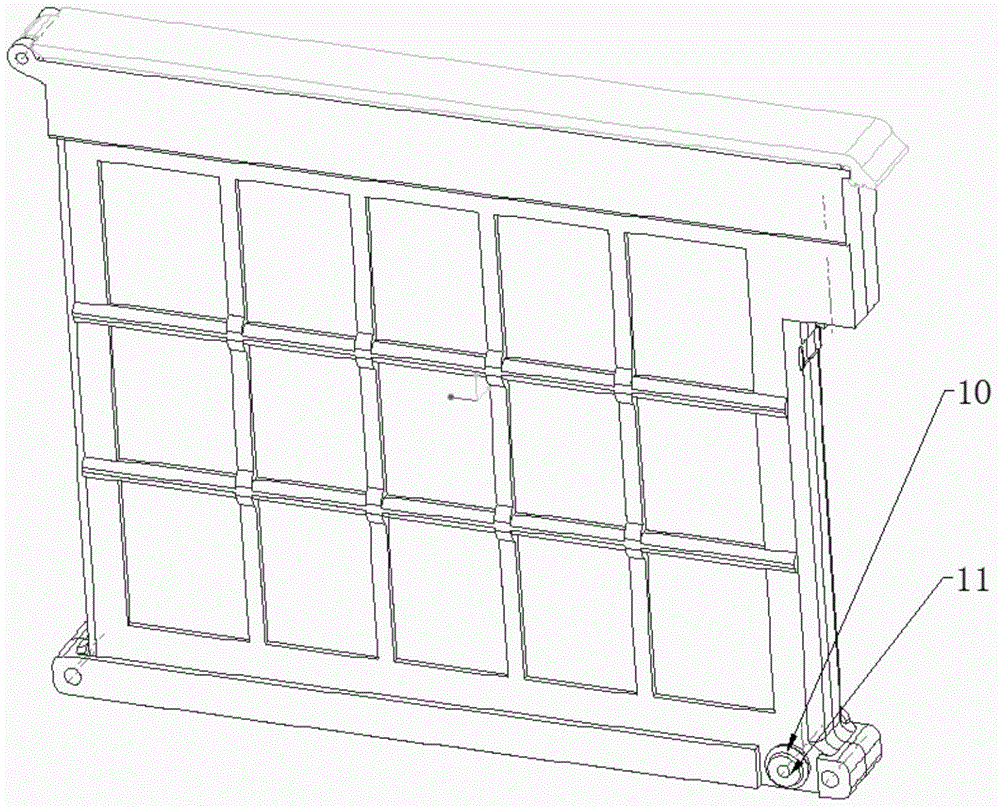

[0041] Figure 1-4 It is a structural schematic diagram of a zinc / air single cell and a battery pack in a zinc / air battery pack in Example 1.

[0042]A zinc-air battery pack consists of six cells connected in series. The zinc / air cell includes a single cell casing 1, a zinc anode 8 perpendicular to the bottom of the cell casing, two air cathodes 4 placed on opposite sides of the battery casing 1 and parallel to the zinc anode 8, and a Electrolyte chamber 22 composed of single cell housing 1, zinc anode 8 and air cathode 4; the bottom of said electrolyte chamber 22 has an electrolyte separator 3, said electrolyte separator 3 separates electrolyte chamber 22 into one end The electrolyte reaction chamber 20 is connected to the electrolyte flow chamber 9; the electrolyte reaction chamber 20 is connected to the electrolyte flow chamber 9 at one end; the injection / drainage hole 21 is located between the electrolyte reaction chamber 20 and the electrolyte flow chamber 9 The far end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com