Breakdown protection device for sterilization of high-voltage pulse electric filed

A high-voltage pulsed electric field and breakdown protection technology, which is applied in the protection of overcurrent, output power conversion devices, electrical components, etc., can solve problems such as excessive size and equipment damage, and achieve damage prevention and stable working performance. , Strong anti-electromagnetic pulse interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

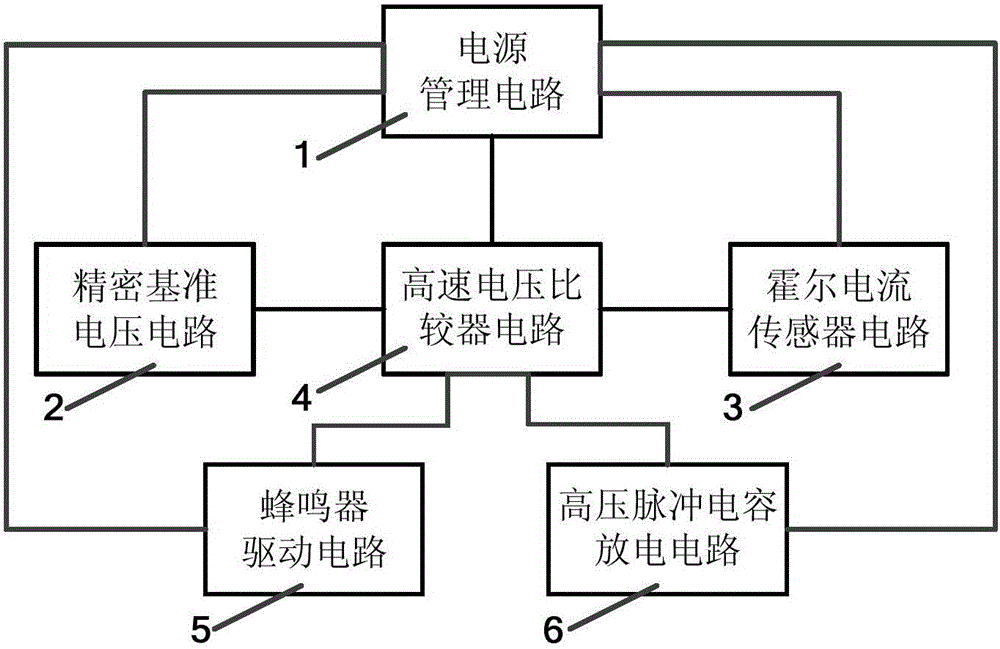

[0032] like figure 1 As shown, the present invention includes a power management circuit 1, a precision reference voltage circuit 2, a Hall current sensor circuit 3, a high-speed voltage comparator circuit 4, a buzzer drive circuit 5 and a high-voltage pulse capacitor discharge circuit 6; wherein the power management circuit 1 They are respectively connected to the precision reference voltage circuit 2, the Hall current sensor circuit 3, the high-speed voltage comparator circuit 4, the buzzer drive circuit 5 and the high-voltage pulse capacitor discharge circuit 6 for power supply, and the high-speed voltage comparator circuit 4 is respectively connected to the precision The reference voltage circuit 2, the Hall current sensor circuit 3, the buzzer drive circuit 5 and the high-voltage pulse capacitor discharge circuit 6 are connected.

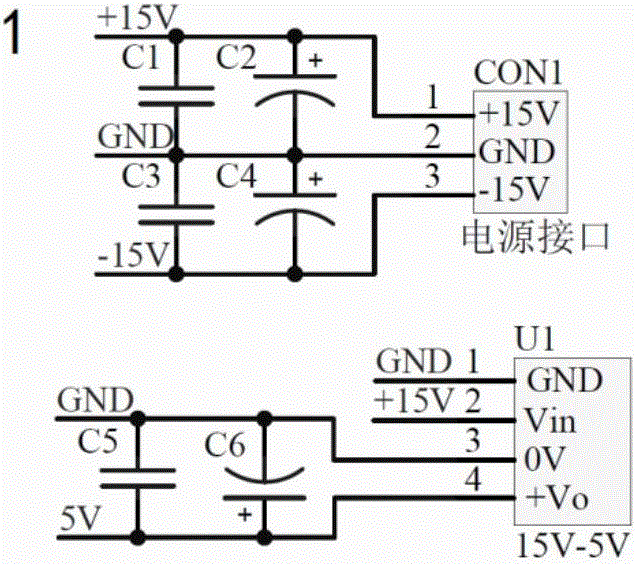

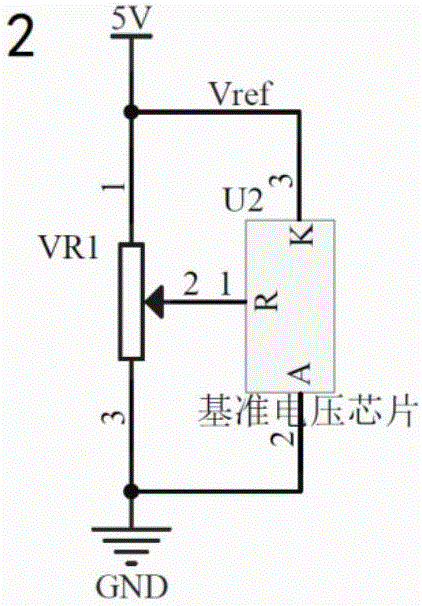

[0033] like f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com